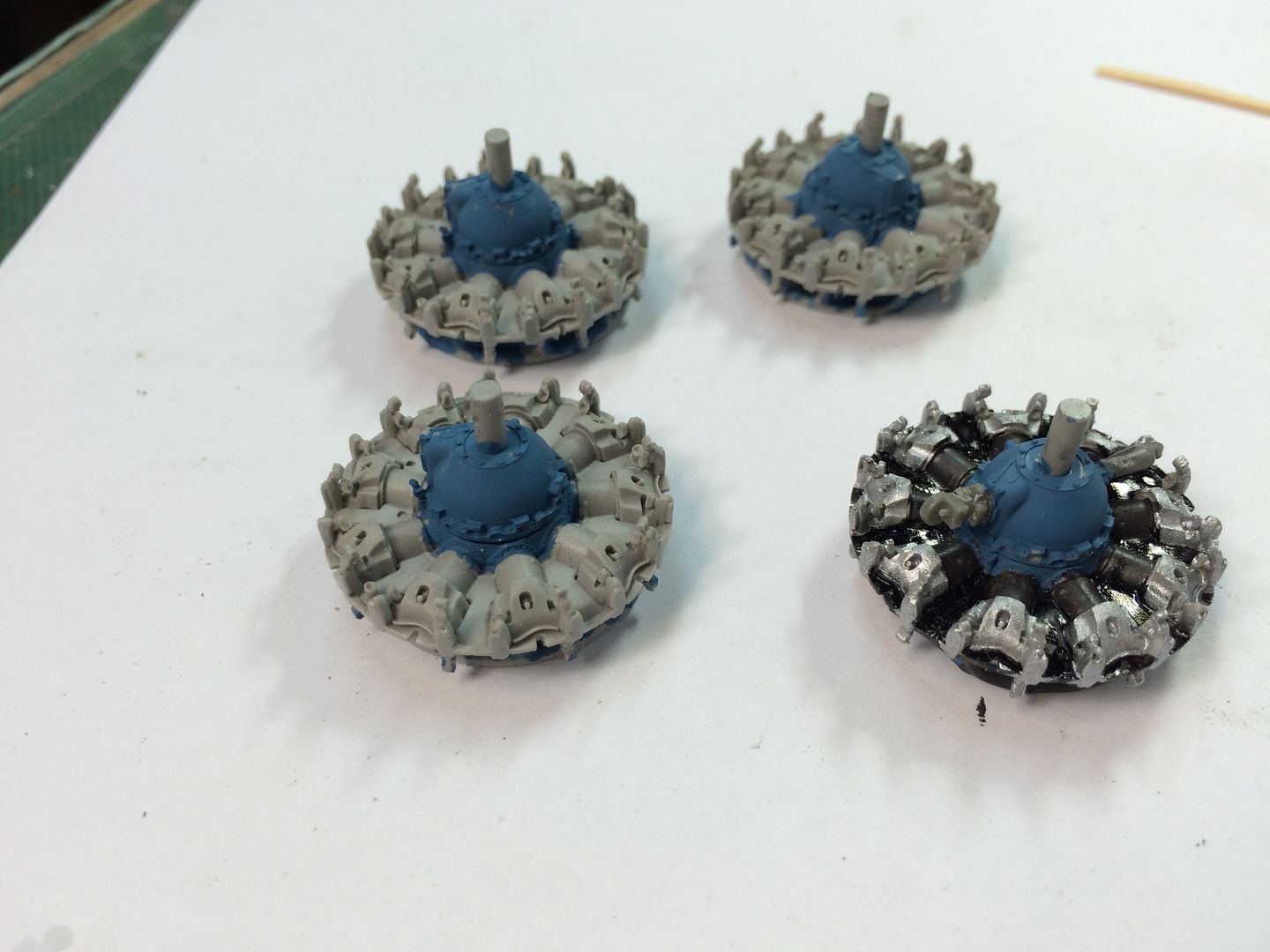

After a light sanding on the gear cases, I CA'd them into the engine block. At this point I need to paint the engines. If you wait until later, everything is blocked by the ignition wiring. After studying some pictures of the R-1800 in B-17s, I chose to paint the cylinder barrels burnt iron, heads flat aluminun, between cylinder baffles flat black and gear case intermediate blue. I think that mix is a little darker than it should be and I may adjust it lighter.

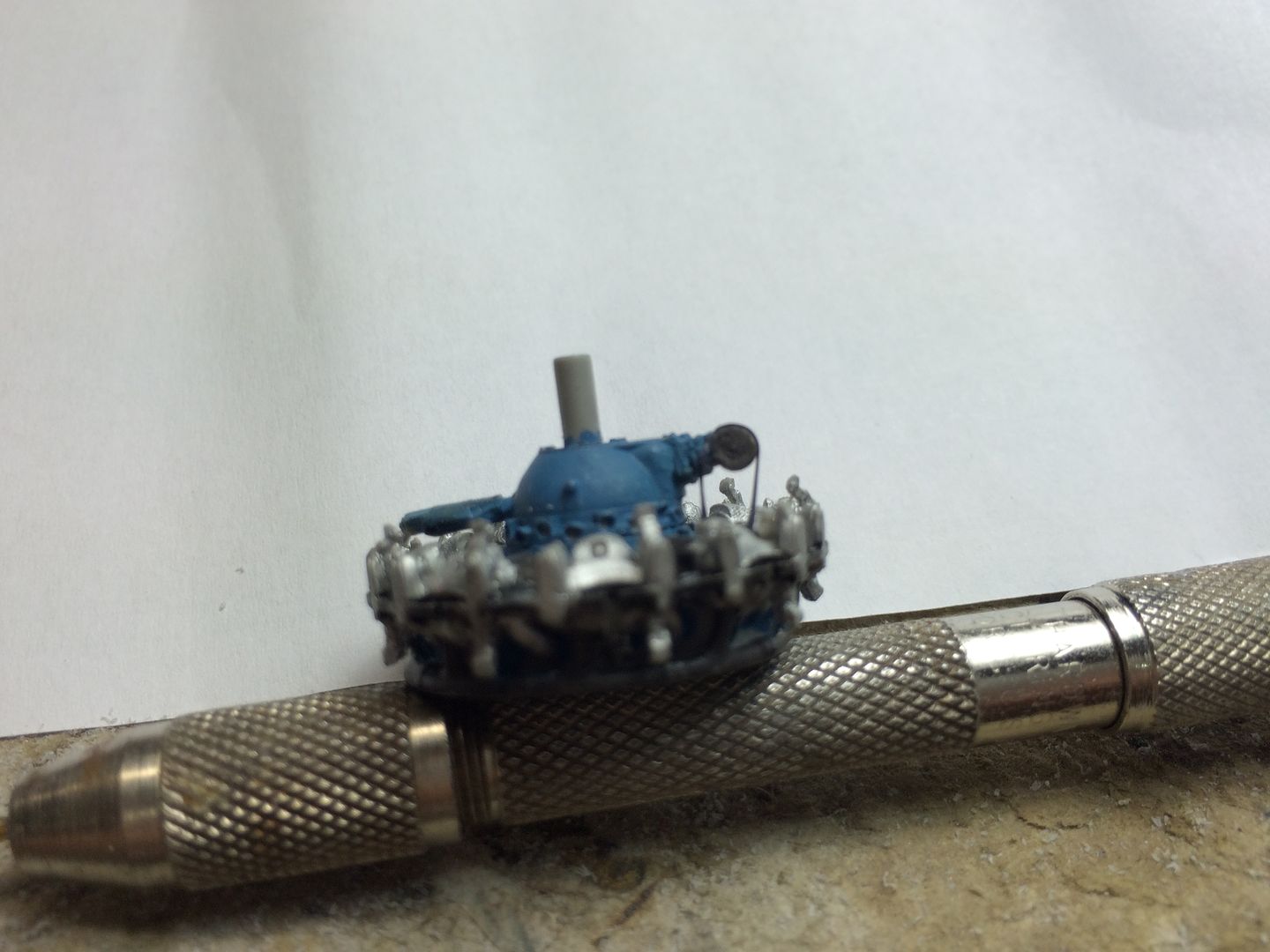

On the right front engine, I glued the magneto and some other component onto the gear case. These are painted the same blue. I made two mistakes here. First, the magneto has a belt drive pulley on it. It's not supposed to face directly back, rather it's supposed to face between those two cylinders. I popped it off and reglued it. Second, neither of these parts should be put on before the pushrod tubes are in place since they partially block where those tubes go and make a tough installation even tougher.

I decided to completely finish one engine to see how to do it before building the other three. Just like the RC model, four-engine aircraft require you to do a lot of things four times. It was really onorous when I had to hand shape 24 balsa blocks for the four nacelles. Ugh!

The magneto has a tiny piece of PE that simulates that belt. It just wasn't cooperating. It was taking close to a half hour to get this one piece on and it just didn't get done. So I needed to find another way. I have the wide and narrow E-Z Line for ship rigging and other cool stuff. One of the nice things about E-Z Line is its instant affinity for CA. I was able to affix it to the baffle, run it around the pulley and then glue it back to the baffle. I added a little tension so it looked like a belt.

I realized that I better start getting those pushrod tubes. They're cast in a block of 18. They're very small... ridiculously small. I'm 71 and need a lot of magnifcation to do this stuff. They also had a propensity to disappear into the quantum rift. For those that don't know about the "Rift". It's the place that small parts go when they pop out of tweezers or leave the work surface for whatever reason. I firmly believe that objects of certain mass or below can actually zip out of our universe and go somewhere else. They may or may not decide to reappear in our space. I've had parts drop right in front of my eyes straight down to the workbench and then... simpy not be there, or anywhere. Then the next day, there's the part sitting right in fron to me. Don't believe there's a rift? Then you explain it.

Well, I lost four of these pushrod tubes and broke a fifth, forcing me to make my own out of .032" brass rod. The model's measured out to .027". I have 0.021 and 0.032 brass so the thicker had to work. I would like to know how Eduard creates these parts in the first place. I suspect they're working in a much larger scale and then using CNC mills to reduce it when making molds. There are details are the rods base that I found difficult to reproduce.

The resin parts should snap into a tiny pocket on the gear case and another under the rocker arm. I found that in most cases I had to remove a tiny amount of stock so they would just snap in without bending too much (that's how I broke one). I had to measure and cut the brass replacements, and then keep adjusting their length and round their ends so they too would just snap into position. A drop of CA at each end secured them.

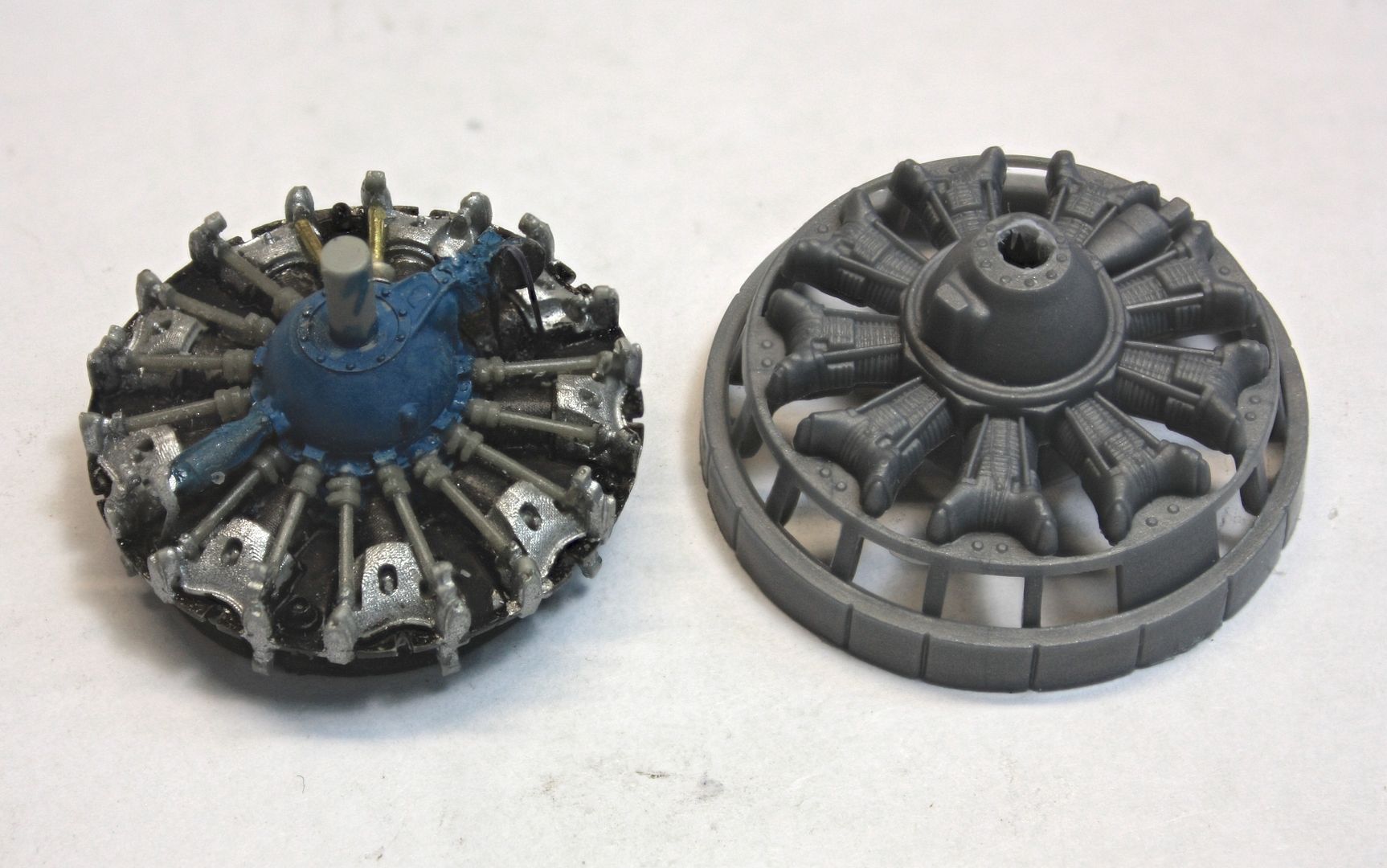

So here's where I am after today's work. I put the kit's plastic part next to this motor for comparison. So much of this cool stuff will not be seen, but I'll know it's there. There are still more pushrod tubes and all the ignition harnesses.

Pushrod tubes will be painted black with aluminum trim at the bottom. Once painted, my brass replacements won't be so noticeable. For the next engine, I'm going to cut all the pushrods off their block first and put them in a container. Some of the parts loss came when my tool bumped the block and a bunch separated and took off.

While building this model I'm also working on my extensive model railroad. Working on little details is a nice break from building an 8 foot mountain out of cardboard and plaster.