As others mentioned, great work going on here! It really puts the boot to the heinie for slow turtle-folk like myself!

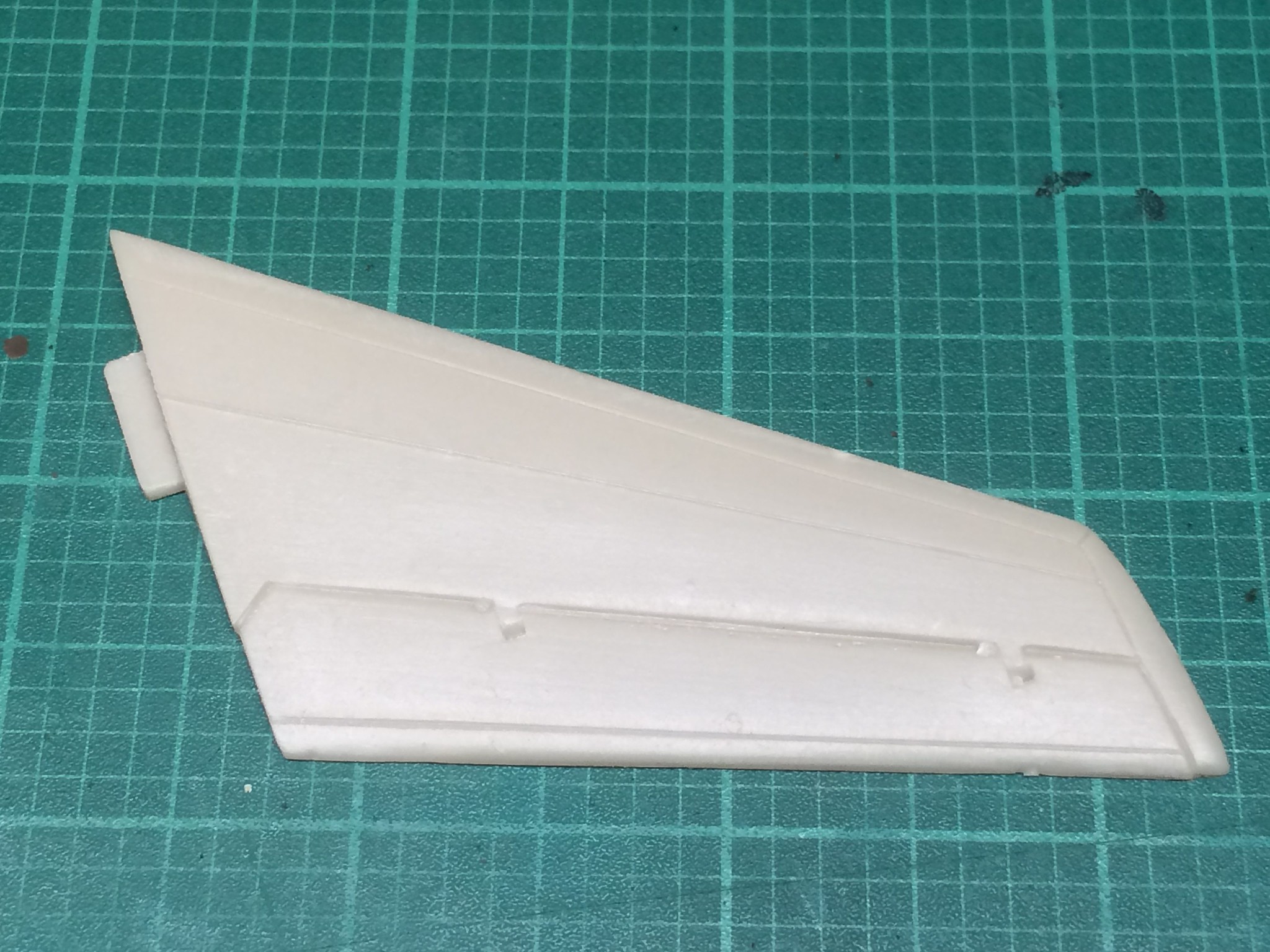

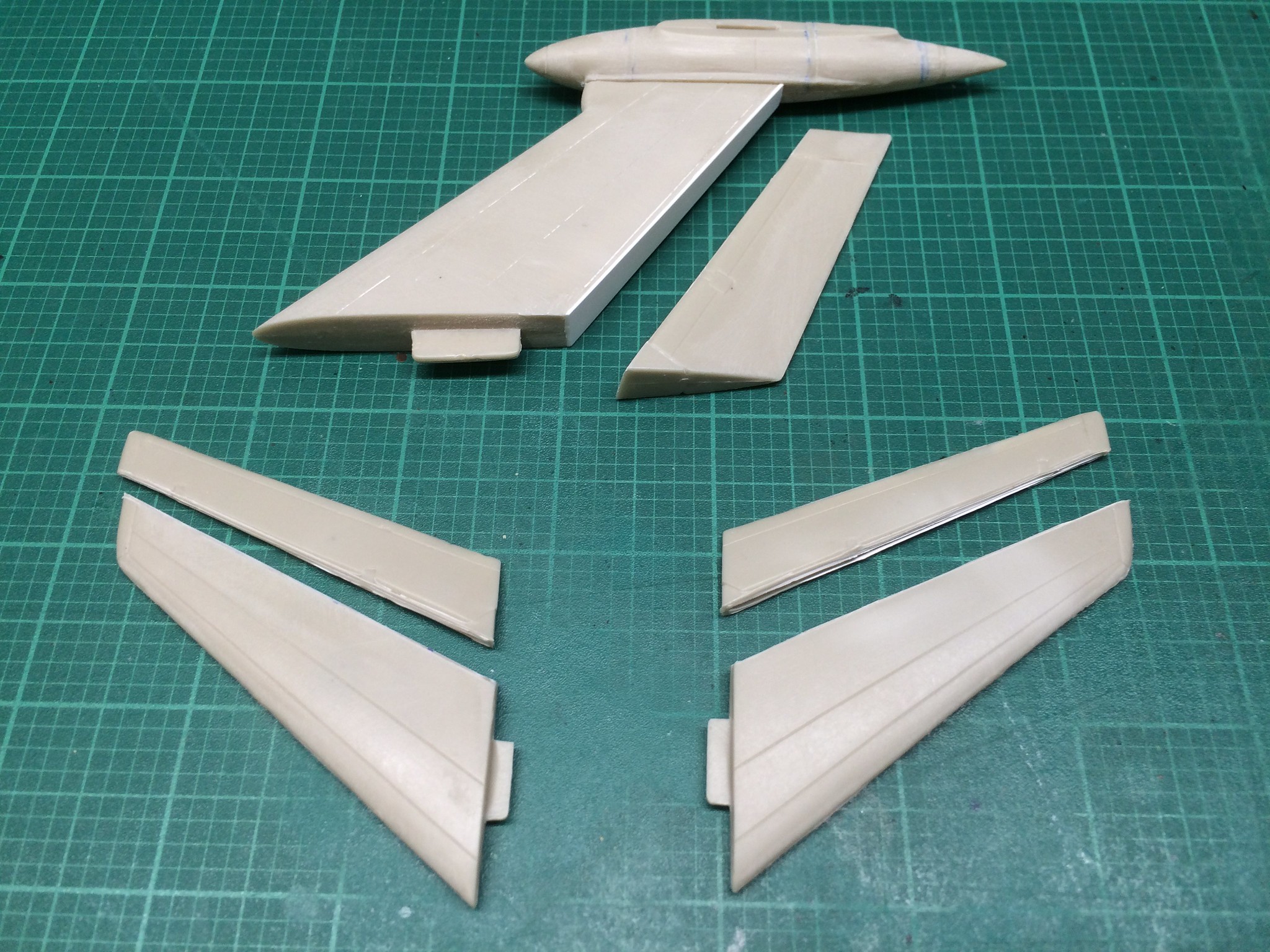

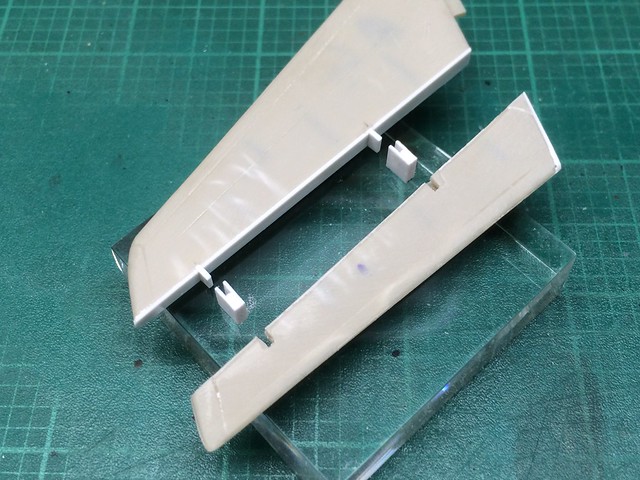

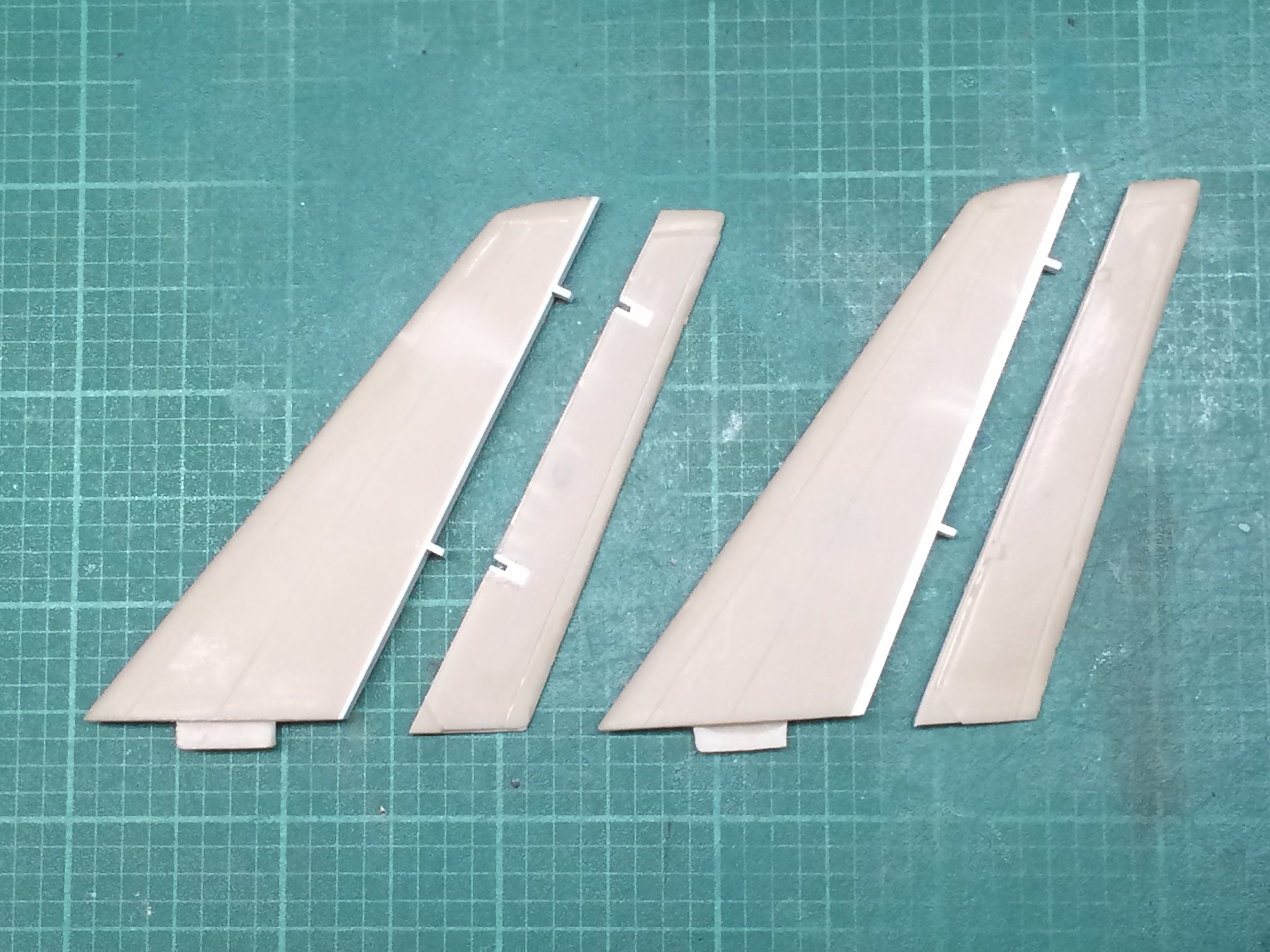

I'm still working on the tail group of the Seamaster. For a Mach 0.92 aircraft, it has very WW II-ish control surface hinge lines, with the fin and stabs having 90 degree edges. Mach-2 just provided deep, uneven recesed lines for these, plus added some globs of plastic in the recesses just to give us something else to fix! To correct this mess, vac-form techniques apply - cut control surfaces away, back the cut lines with sheet plastic, rebuild hinges, then sand everything down until it looks right.

https://flic.kr/p/HRYvUS] [/url]Seamaster-22 by N.T. Izumi, on Flickr

[/url]Seamaster-22 by N.T. Izumi, on Flickr

https://flic.kr/p/HBLBHs] [/url]Seamaster-31 by N.T. Izumi, on Flickr

[/url]Seamaster-31 by N.T. Izumi, on Flickr

https://flic.kr/p/Hibyaf] [/url]Seamaster-36 by N.T. Izumi, on Flickr

[/url]Seamaster-36 by N.T. Izumi, on Flickr

https://flic.kr/p/J7Gizi] [/url]Seamaster-37 by N.T. Izumi, on Flickr

[/url]Seamaster-37 by N.T. Izumi, on Flickr

https://flic.kr/p/J2kvLp] [/url]Seamaster-33 by N.T. Izumi, on Flickr

[/url]Seamaster-33 by N.T. Izumi, on Flickr

It is tedious, but extremely easy and does not require a lot of measuring or precision. Easy-peasy Japaneesy!  But day-um, the parts sure are wavy!

But day-um, the parts sure are wavy!

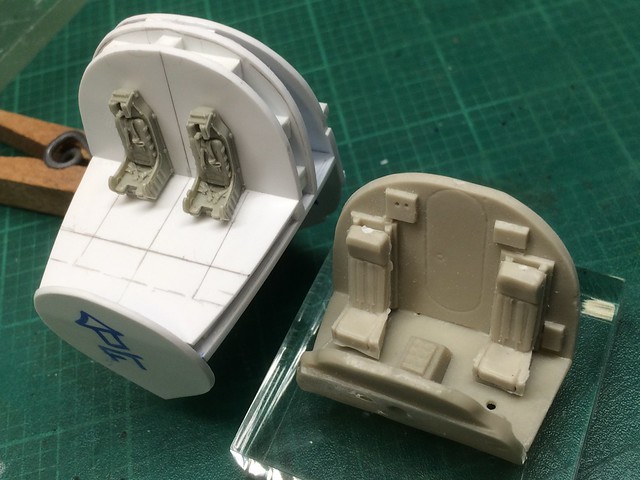

I also started looking at the cockpit. Laying out the positions of the seats and consoles reveal a marked difference in what Mach-2 provides.

https://flic.kr/p/J5oWry] [/url]Seamaster-38 by N.T. Izumi, on Flickr

[/url]Seamaster-38 by N.T. Izumi, on Flickr

The way the Mach-2 kit is, the pilots would be squinting through the small curved triangular side windows (of which Mach-2 thoughtfully molded an extra frame going through them), rather than through the large flat-paned windscreen. But make no nevermind, as a new canopy will be vac-formed. I also noticed the real seat in the Seamaster had their backs extended a bit, so the True Detail seats will be modified accordingly.