Brandon, that is a right bang on job on that Bristol.

Would never have guessed this was your first bipe, will you be building more?

Hello Nick, thanks!

LA, thank you. Man that looks to be quality control issues on that Airfix Lightning, reminds me of the missing engraved detail on a new tool Emil I had.

---------------------------------------

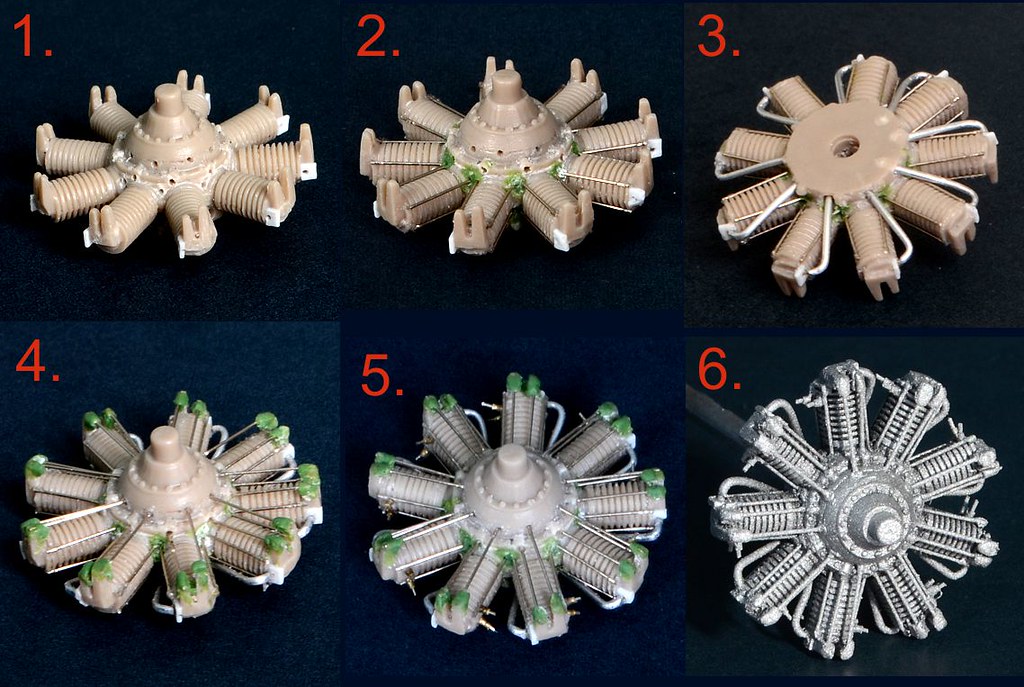

The Bently BR1 engine construction is complete, and already has a coat of paint. I've further outlined the steps I took to build it if anyone is interested, but just some quick numbers:

- total number of holes drilled: 54

- total number of sections of cut rods in various diamaters: 99 (11 pieces per cylinder)

1. - all push rods removed, drilled location holes in their place. Also added small sections of plastic sheet to the top sides of the cylinder heads. These also had location holes drilled for the piping that reaches out from the backside.

2. - each cylinder is surrounded by four rods, using 0.2mm size (same diameter as push rods). Decided to just drill one large hole to fit two rods as they come down into a V - but each hole was first packed with green putty.

3. - piping added in the rear, using 0.5mm rod. To aid in attaching to the cylinder, the curved end of the piping also had 0.3mm rod inserted to fit into the sheet plastic added in step 1.

4. - push rods finally added (0.2mm). The green putty was added afterwards for additional strength, but not really accurate in terms of detail.

5. - pair of spark plugs added to the top sides of each cylinder - no holes drilled for this. Basically just a 0.2mm rod inserted into 0.4mm section and super glued in place.

6. - Base coat of black followed by aluminum, ready for further detail painting.

regards,

Jack