Thanks Bufflehead, I usually store the completed model in the shop covered up with a tarp or old bedsheet to keep from getting dusty.

I've been slow with updates recently, with all of the orders and commission builds going on I have had little time for my own projects :S

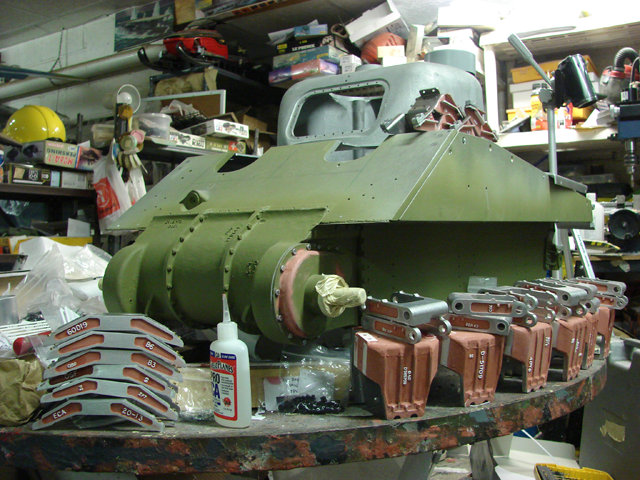

I was able to complete and install the tank's suspension.

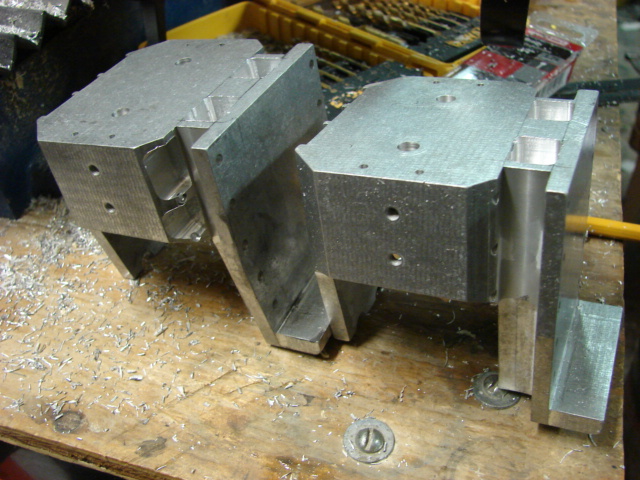

Like I mentioned in the last update post several surface mods were made to the armortek VVSS suspension.

The VVSS suspension on this version on the armortek sherman has almost the exact same layout of their first offering, but with a few minor differences. The biggest is that the bogie housing and the wheels on the first release was made out of cast aluminum, while this release utilizes CNCed Aluminum it their place.

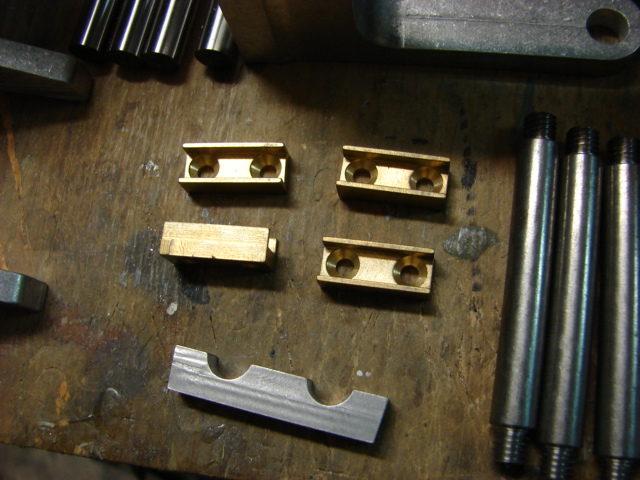

The CNCed parts are just as, if not more durable as their cast alloy predecessor. Some other improvements include Brass CNC slide rails for the H frame mount, as well as limit restricted swing arms and spring tension bolt cover caps. All of these were not present on the first release.

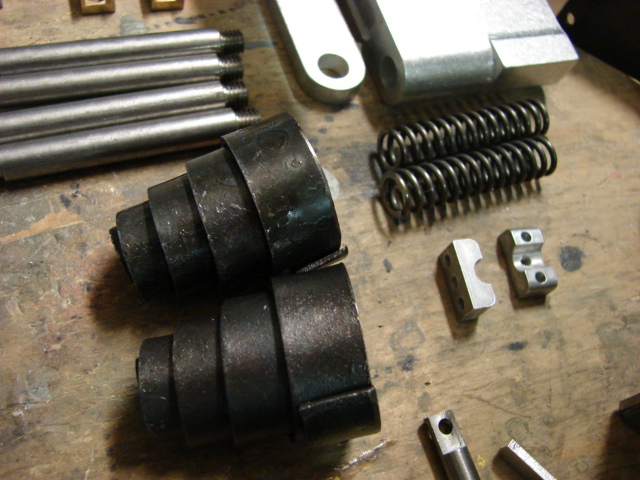

Besides the listed above the rest of the suspension parts were kept the same, and worked very well on the first release. This includes the Volute springs, return roller, skid rail, and H frame.

The armortek kit VVSS suspension is a solid well designed and proven unit, The unit is the right shape and scale, and assembles easily. You can mount the unit to the model OOB, and it will give a lifetime of reliable trouble free service. The unit was also a good base to start with to add the surface details resulting in the completed unit below.

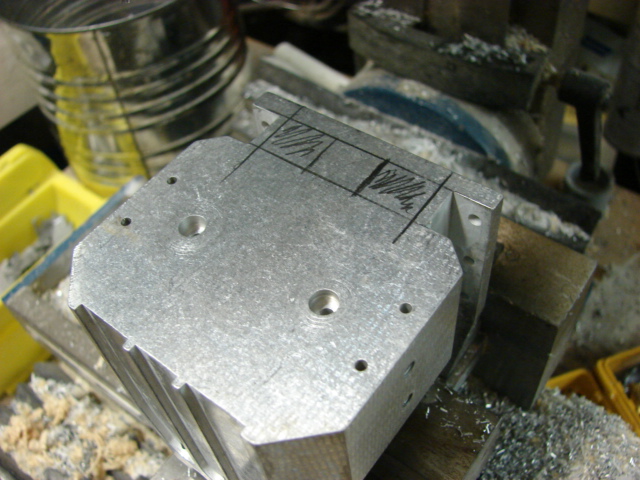

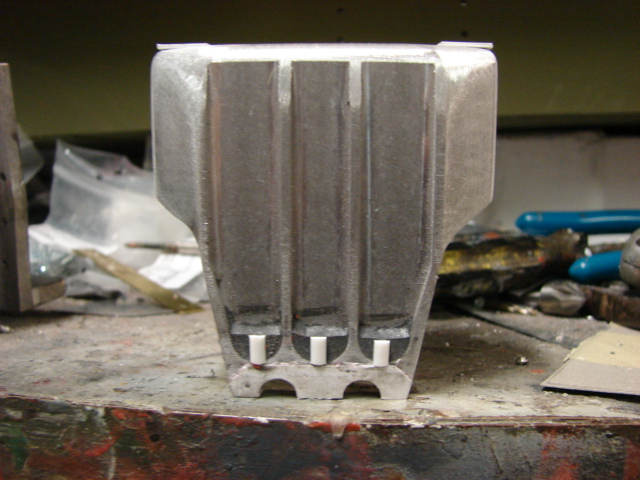

To start the transformation I wanted to add the top bogie fastener wells.

On the real sherman bogie the bogie casting had two rectangular squares integrally casted into the top rear portion of the bogie to allow two fasteners to be fitted in to bolt the unit to the tank.

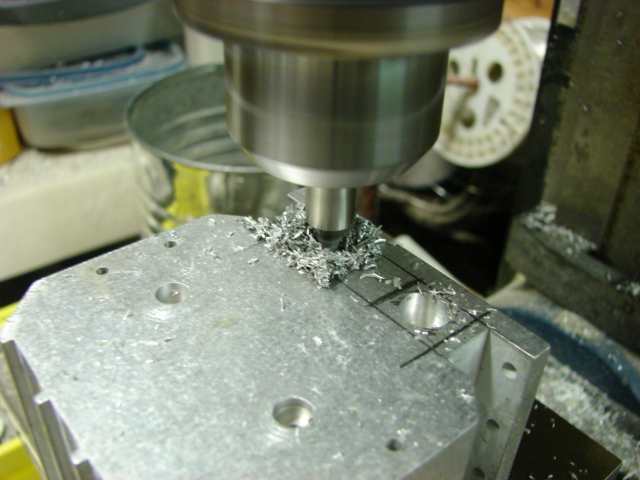

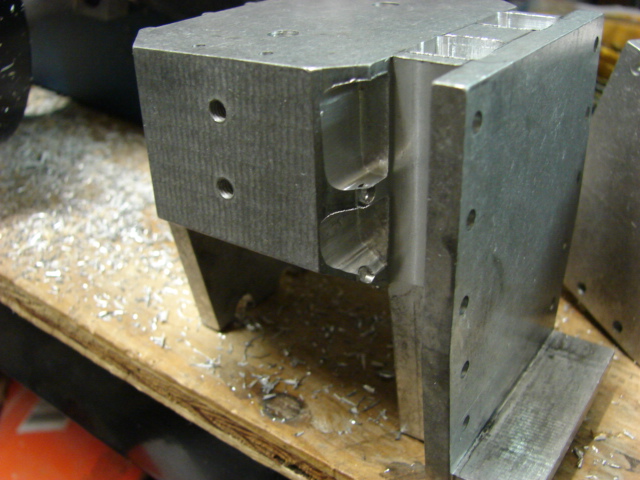

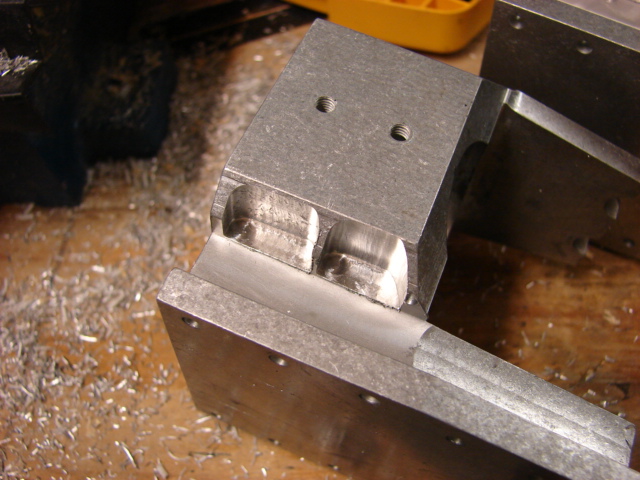

After marking the locations I first drill a hole to the proper depth, once the hole is drilled I then square off the round hole on the Mill.

The drill bit that I use is the same diameter as the hole which also saves time in squaring off the recess.

After the holes were added two small hex bolts were fitted. These bolts are for detail purposes only and are not needed for structural strength.

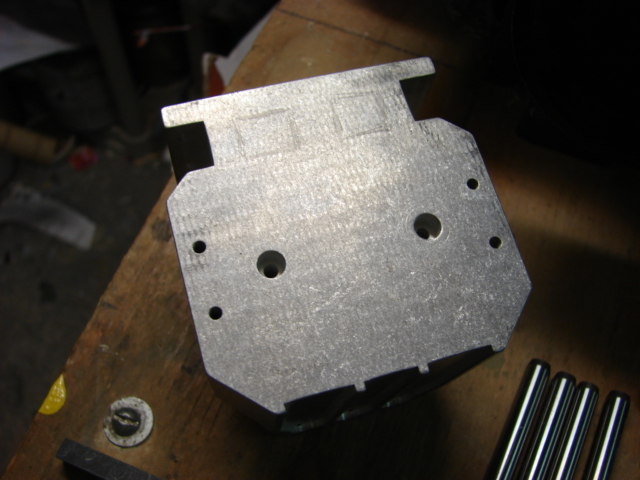

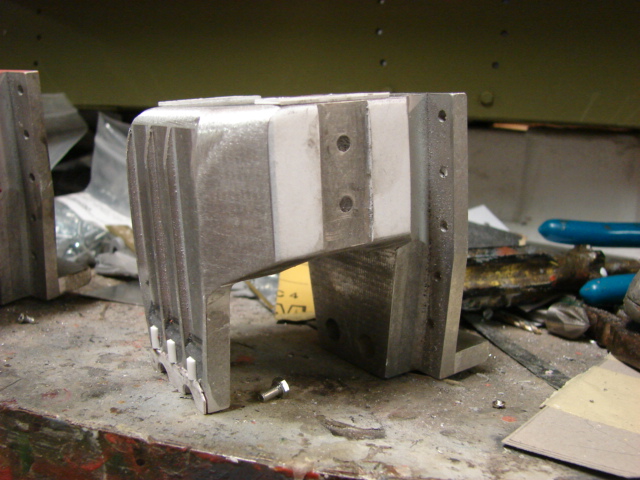

Another mod that was made to the bogie housing was adding the rear wrench wells. On the real sherman the rear portion of the bogie housing had recess casted into the housing to allow the mounting bolts and the wrench more clearance when installing the unit. To add this feature I milled away the needed material.

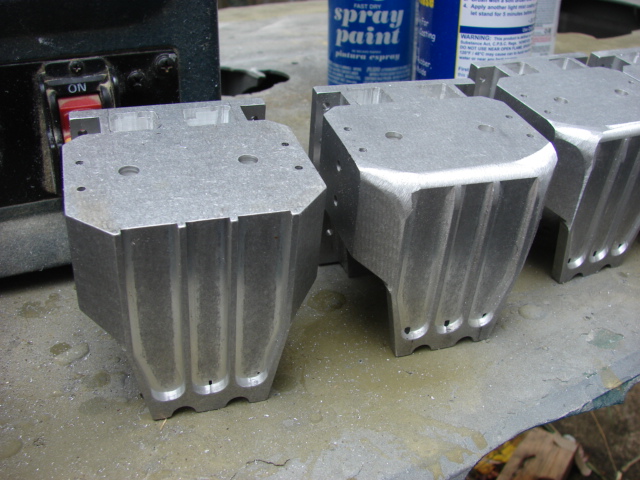

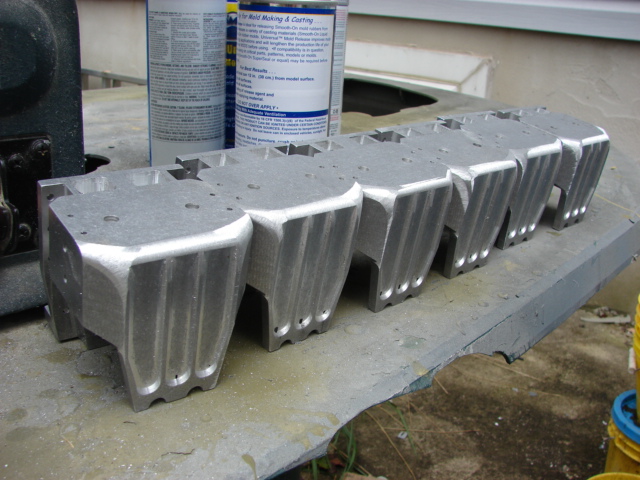

Because of the CNC machining process the bogie bodies have a squared off appearance to them. I decided to round off the bogie bodies on the belt sander to give them a more rounded edge look to them.

Another common feature that the bogie housing has on the real tank is that the roller mounting area features a milled center, and on top two elevated casted in mounts for the skid rail / roller mount to mount to. Rather than milling these details into the housing I instead added sheet streyne strips to the alluminum housing, as well as adding the other integrally molded in detail (rigidity nubs) to the body.

After the plastic parts were all added they were all blended into the bogie face via the body work. In addition to blending in the surfaces the bodywork also gave the bogies the cast texture appearance. In addition to the bodywork cast and foundry numbers were added to the parts.

The casting texture and foundry marks were also added to the other suspension parts as well including the swing arms, H frame, and roller mount.

Another feature that is common on the sherman bogies is depending on the foundry some bogies have a cast seam line that runs along the top portion of the unit. I built both seamed and seamless units into my model as having different foundry marks / features was common on these vehicles.

As I mentioned above the return roller mount uses the same design as the first release. That design uses two cap screws to Bolt together the roller shaft mount, and sandwiches the rigidity strip to the roller mount. On my model I replaced the cap screws with counter sunk Allen bolts to lower the profile of the fasteners which will help them blend in better with the bodywork. I only did this mod to the axles that are on the visible portion of the mount.

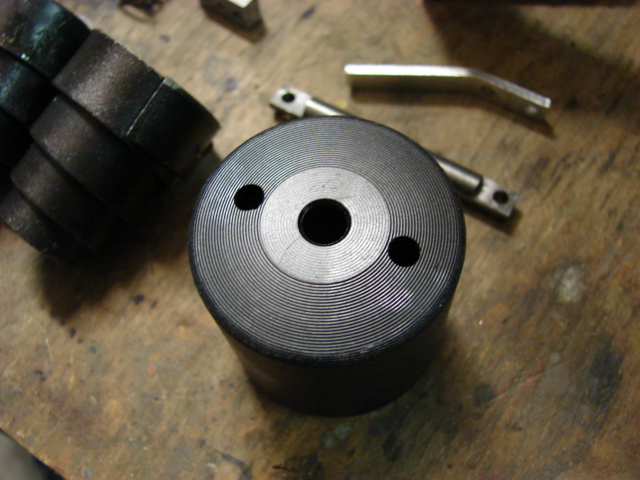

Once the bogie body mods were complete I turned my attention to the road wheels. The kit supplied wheels are all CNC and are very strong / durable.

Like the DML sherman the wheels have face detailing only.

Along with developing a DML wheel insert (coming monday ;) ) )I also tooled up and used a similar design for the Armortek sherman tank.

The pre sized insert simply drops into the wheel well filling up the space that was left in the kit. The wheel also has it's zerk fitting wells added.

![]()

Also included in the set are covers for the return roller fasteners, The set has been added to the sherman parts catalog, http://eastcoastarmory.com/m4.htm

Also added to the product line was the early war style mini rear fenders. The fenders are fabricated out of sheet metal, and are all soldered together. They will also work on other early war ear shermans such as the Viper.

The return rollers also had some detail improvements made to them. On the rollers I added the zerk fittings, collar detail, and I plugged the two plug holes. On the collar I recycled my resin Vantex bogie detail set collar for use on the armortek. To install I had to first machine in a recess into the wheel, to allow the resin collar to fit flush and out of the way from debris impact.

As for the plugs I snipped several lengths of 5/32nd brass rod and inserted the new pins into the pre drilled holes on the kit rollers.

Before everything gets assembled / installed the parts all get primmed, painted. In the case of the road wheels they also got their weathering as once they are installed getting access to them is more difficult.

Once all of the paint work is complete the suspension is affixed to the model.

A youtube video update was created showcasing the progress and discussing other details that I left out of this post, http://youtu.be/yQA4gP87SY0

Also more pics were posted on the facebook page,

http://www.facebook.com/EastCoastArmory

with the suspension now out of the way I can focus on working one the drive sprockets and the rear idlers. More progress to come!