Hello everybody! It's been some time, but I didn't want to bore you all with fotos showing puttying and sanding.

Steve - thanks a lot, I appreciate it!

holdenmaniac - welcome aboard! Well, to be true, it was more my fault than my merit... I just used tube glue many years ago on some places and then I didn't scrape the paint away in other places... So these joints can be pried apart pretty clean, as long as you use some "feeling" doing it. Having assembly instructions at hand is helpful, to know exactly where the part joints are. Where the glue holds like it should, a razor saw is most helpful. I made mine myself, by filing an old razor blade (you can hardly find one nowadays). Other than the "feeling" you also need luck, and then it can be done.

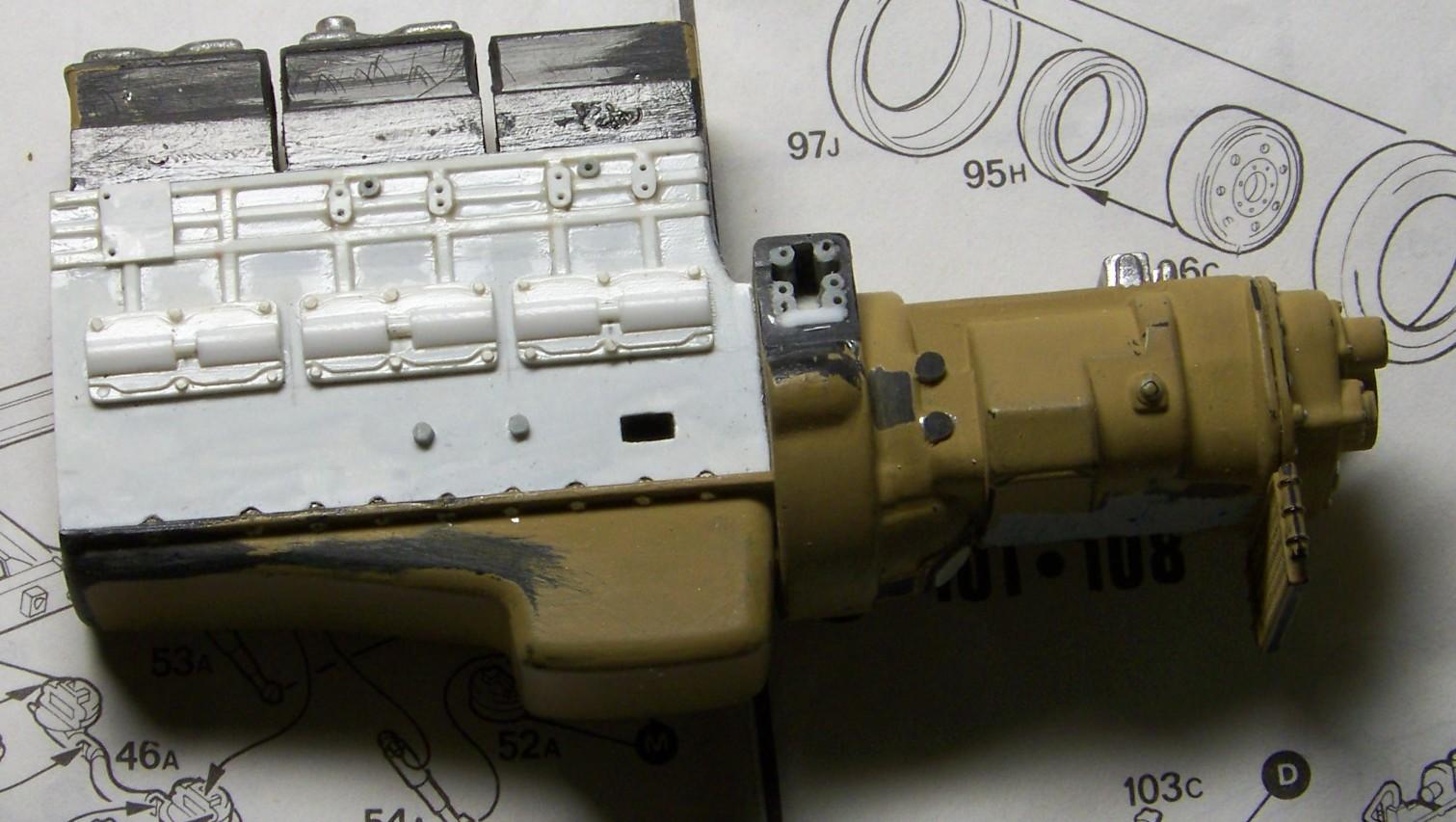

But I also have a bit of an update for you! This time I put some more work in the engine and the rear suspension. I added yet another casting details on the motor block and I also depicted the motor mounts taken off the flywheel housing - on Macks the power pack hangs by the tranny, by the clutch housing to be exact. This way the torque is carried better by the pack and by the frame too. Here's a picture

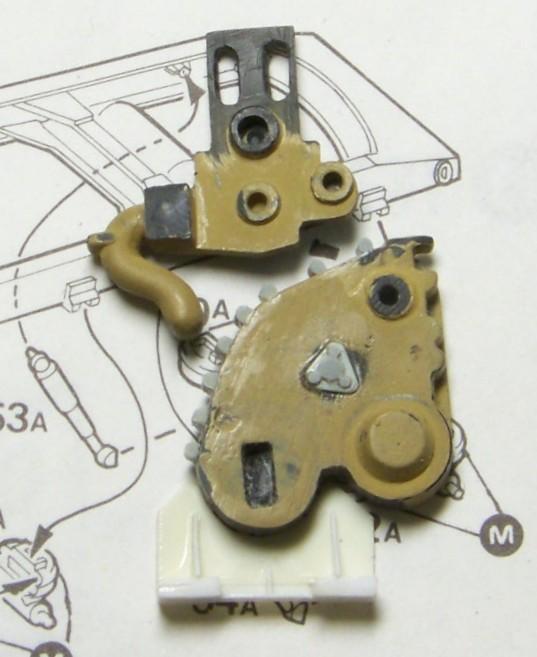

I also worked on parts mounted on the front of the block - the chain cover, the motor mount, which I scratchbuilt, and the upper part containing the water pump and the radiator fan bearing:

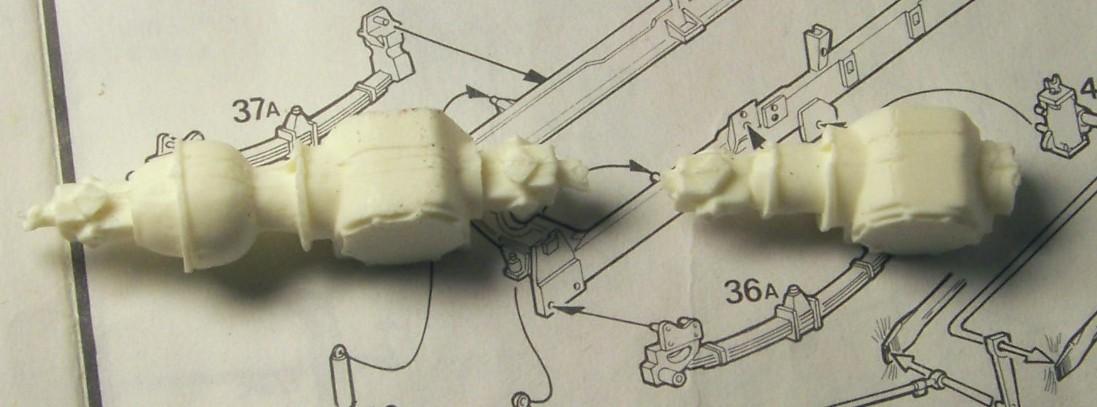

Moving over to the rear suspension, here are the gears as I got them:

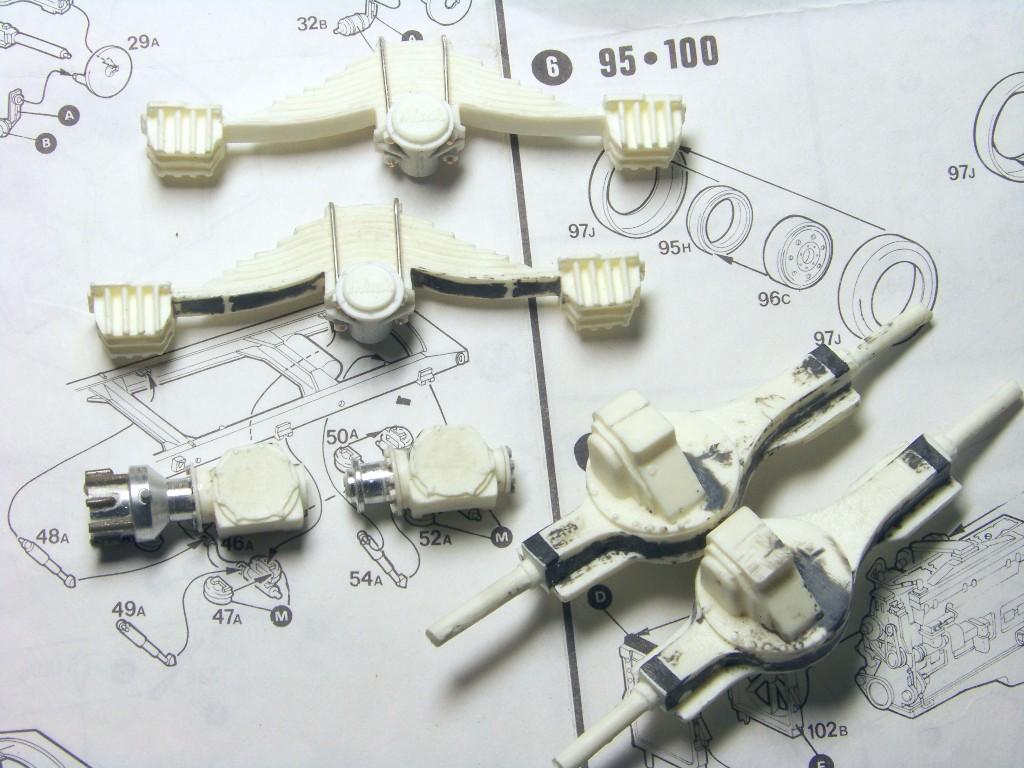

Instead of cleaning them up intensively, I decided to build a portion of the gears myself, using turned aluminium parts I fabricated myself. After it was done, I finally had all the parts for the rear suspension:

I still need to do the brakes, but I hope to have a complete rear bogie soon, so please stay tuned and have a nice day

Paweł