UPDATE29 – 3/29/2014

Hi Everybody!

Before doing the decals, I decided to add the VOR/LOC antenna on the vertical stabilizer, as show below.

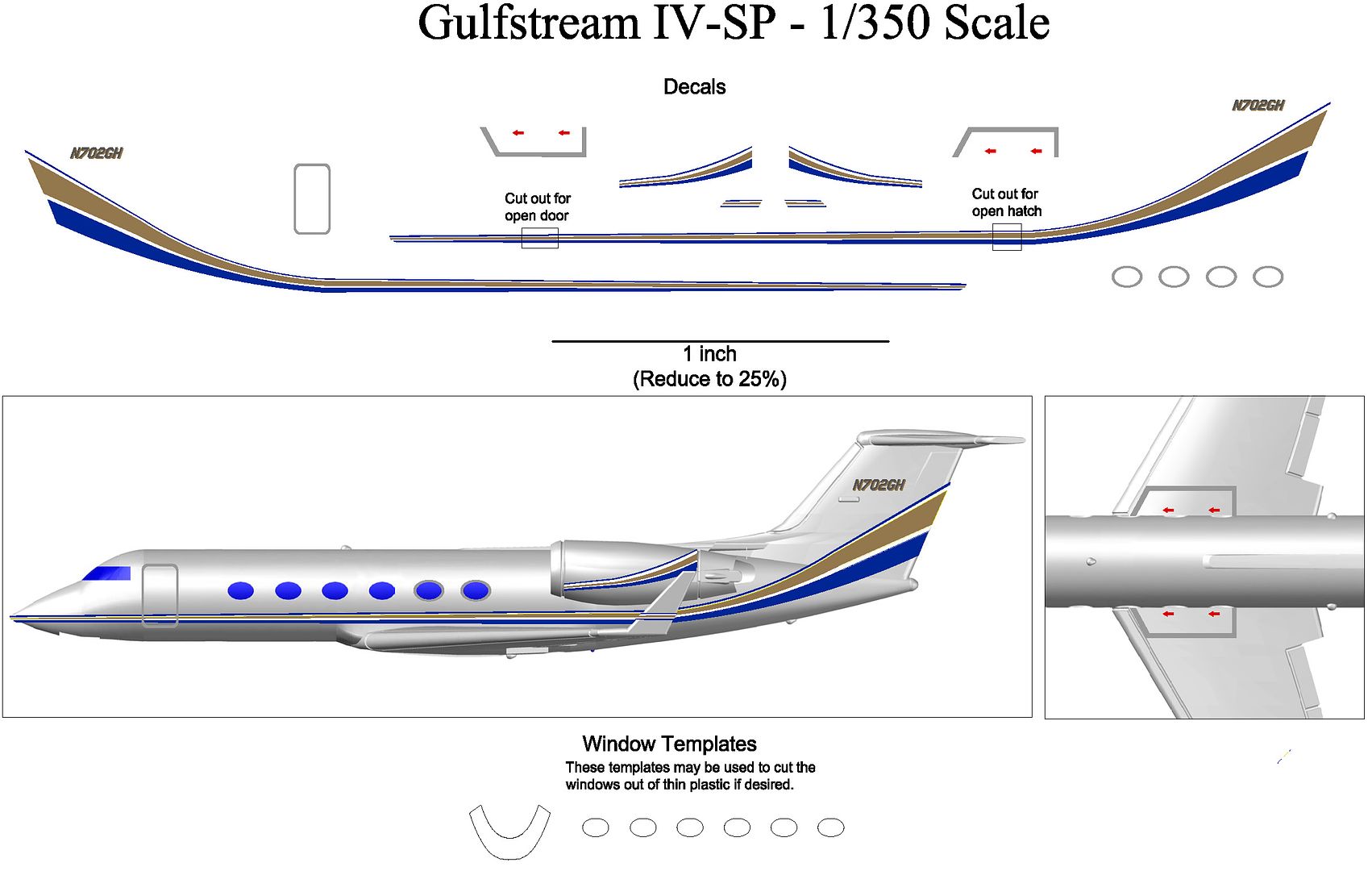

To make the decals, I used this side view of the aircraft.

I did the decals in Paper Space with the model in a view port so I could draw over it easier. I started with the fuselage markings which consist of 5 enclosed polylines, 2 blue, 2 white, and a tan. Note that the markings are above the winglet. Next I added the letters using Amarillo USAF font that I italicized. I then traced the letter outlines of the letters and numbers, modifying the 7 and G slightly in the process. The tracings were then copied twice (down at a 45 degree angle) The outlines were then diced, sliced and rejoined to form the tan shadow, seen below.

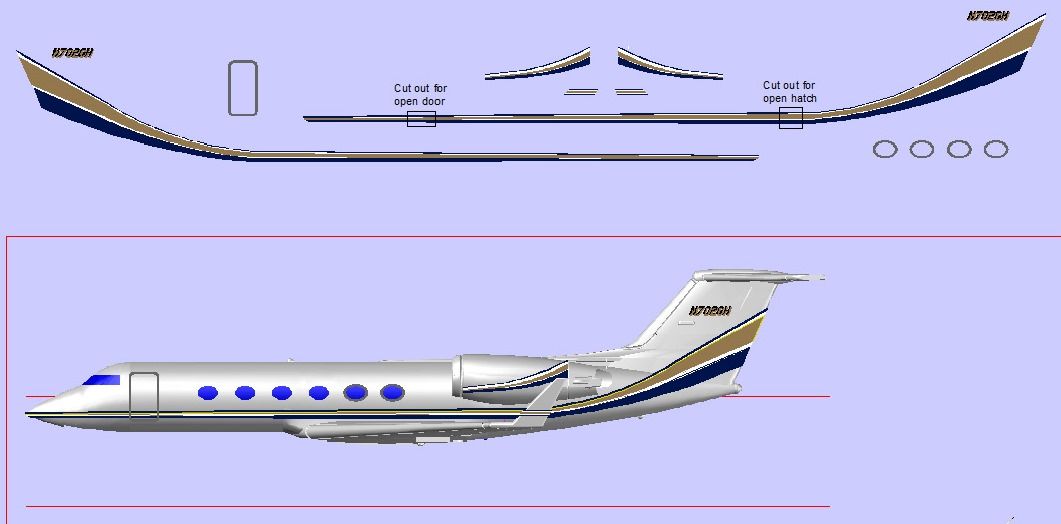

The image below shows the decal sheet in progress. I have mirrored the port side decals for the starboard side decals and marked where the door openings would be. I also made the gray outlines for the aft four windows and the door. Note that I made the background light blue and changed the color of the aircraft to white. After all, that’s what color it is in real life. I also trimmed the decal set over the model, so it would look better. The actual decals are not cut. Last, I copied the port side engine just below the airframe.

In the image below, I have completed the markings on the engine and winglet, mirrored them and copied them all up to the decal section of the sheet. Note that I then trimmed the engine decal on the aircraft side view so it wouldn’t cover the winglet.

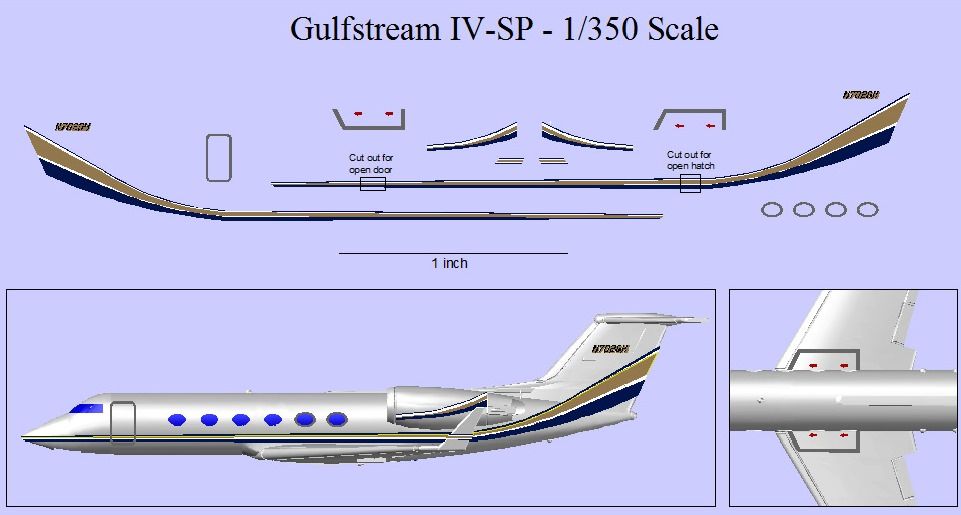

At this point Ron sent me a picture showing the wing walk outlines, so I added them, as seen below. I also added what appeared in the picture Ron sent to be Red arrows, which may or may not be correct.

For those who may wish to cut the windows out of thinner plastic than the 3D printer can do, I added templates that may be used for this purpose. The first draft version of the sheet is shown below. It was designed to fit on an 11”x17” sheet of paper and needs to be reduced 25% for proper scaling.

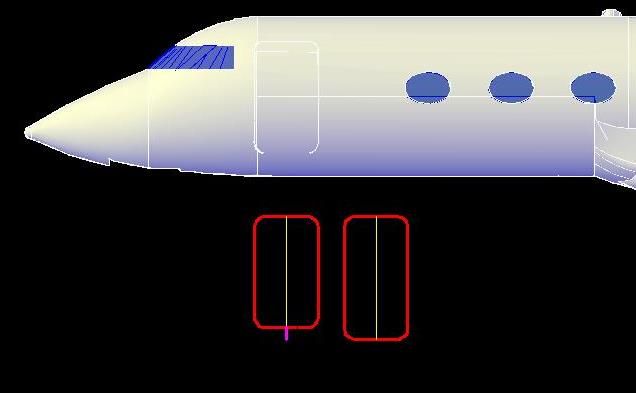

Note that I said first draft. This is because I know it is going to need modification, because curved lines are longer than straight ones. Consider the door shown below. The outline of the door that I used to cut it out of the fuselage ison the left, and the outline of the gray door decal is on the right. Note the extra length, 0.02" to be exact. This is because the decal is on the circular surface of the door. The length of the decal is the arc length associated with the chord length of the airframe diameter.

The door was easy to do, the fuselage decals, which are curving on a surface that is curving in two directions, is another matter. I know that the decals need to be lengthened in both directions, but I have no idea how much. You can break it down into 4 sections, the nose (from the door forward), the body (where the sides are straight), the aft end, and the tail. The body and tail surfaces are essentially straight so no length adjustment is necessary, but the nose and aft end are a different story. The increased length on the nose, I think I accounted for by adding some length up front. It may or not be enough.

The aft end starting at about the winglets in the side view, is essentially a cone, so it curves on 2 planes. If the markings were straight, it would be difficult but with them curving too…, Man, I can't figure out how to do it. I know that it needs to be at least 0.02" longer in the vertical direction, but how much longer in the horizontal direction, I don't know. And the really hard part is that the stripes don't all need the same amount of stretching. This is definitely a thought provoker. Does anybody have any tips on how to approach this issue? Any and all comments would be appreciated.

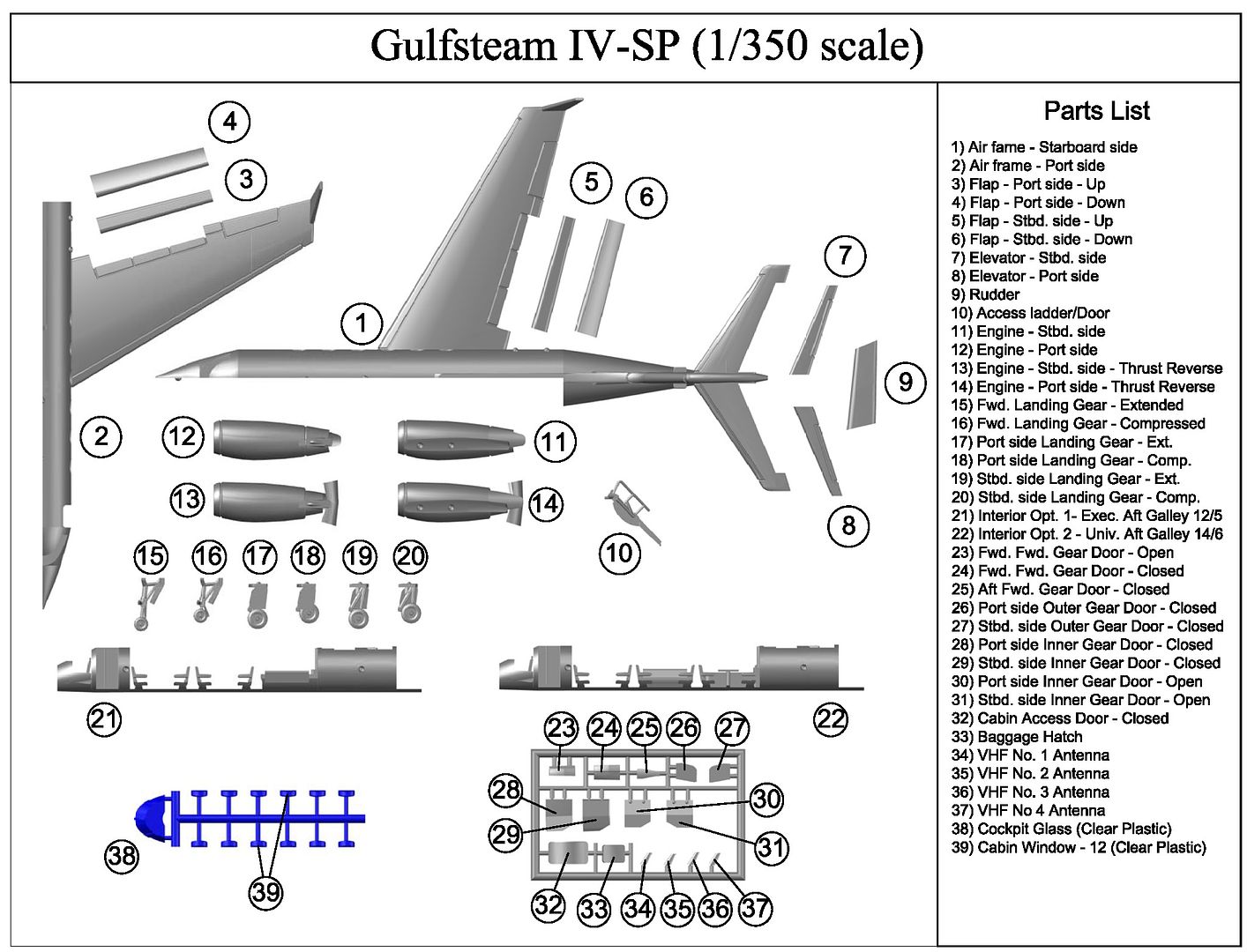

In the meantime, I made some minor modifications to the Parts List and Diagram. The final version is shown below.

CHEERS!!!