goldhammer

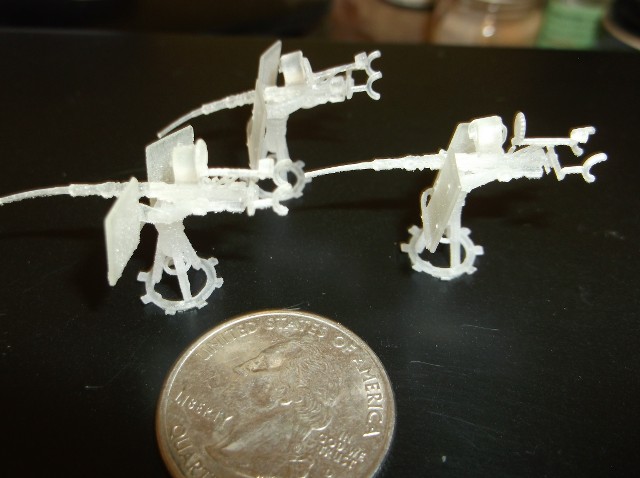

20mm's. Have to remove the shields and straighten the barrels.

If anyone has fooled with the 3D material and has suggestions I'm open to hearing them. Don't know if warming them up in warm water or a hairdryer will do the trick. I know they will harden up under UV in sunlight.

From Model Monkey's tips:

How can I fix warped acrylic plastic parts? Sometimes microscopic bits of uncured resin remain within the acrylic plastic. This is a normal characteristic of 3D-printing (this does not affect metal nameplates). The presence of uncured resin can permit acrylic plastic to warp when wrapped tightly for shipping. Should you receive a warped acrylic plastic part, no worries! Tape the part to a sturdy, flat surface with clear "Scotch" or cellophane tape in the desired flat or straight position. Set the part in direct sunlight (or place it under a UV lamp) for a few hours. Any uncured resin will fully harden when exposed to UV light. The now fully-hardened plastic will remain flat or straight when you remove the clear tape. Clear tape is recommended because it helps UV light reach all of the plastic and fully cure all of the resin.

I would think the above tip is dependent on the material used.

Maybe request replacements or inquire if a replacment can be sent if the above warpage is not Fixed by the Tape-UV light method.

Nino