Sherman II at El Alamein: Construction (Final Assembly)

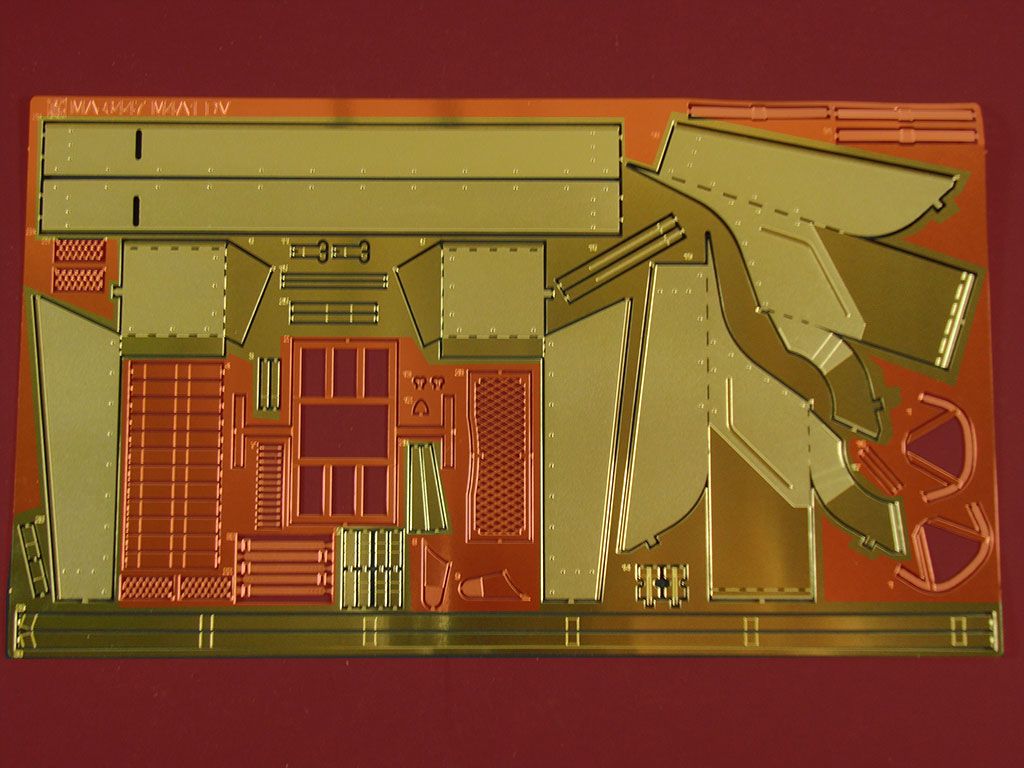

I’m in the home stretch for assembly now. The last things on the list – and they are big things – are the photo-etch sand shields.

The sand shields consist of many PE parts but the main structure – and there is one on each side – consists of three large pieces: the front “fender” which curves around from the transmission cover to the side, a flat panel which runs about three-quarters of the length of the tank, and the rear “quarter panel” which covers the last quarter and takes a sharp 90-degree turn around the back to the air filters and exhaust. In addition to the big pieces, each shield gets a handful of details.

If you’ve read any other modelers posts on these beasts, they sound quite intimidating. Still, I thought, “How bad can it be? I’m sure some thick CA and CA accelerator can handle this.” But, after I started folding them, I had second thoughts. Of all the parts, the ones that had me most concerned were the front fenders which need to be rounded something less than a perfectly round arc. After playing with it, I realized that the only way to get it all to fit together nicely and stay was to solder it.

Being my first foray into soldering, I read about how to solder PE on the internet, went to RadioShack buy a soldering iron and supplies, reread the internet articles, and plunged in at my first attempt at soldering. After the fact, I found this great article about soldering Sherman fenders from Dragon kits which I highly recommend to anybody about to embark on a similar project.

For those that haven’t soldered before, there are two approaches to it:

The first – which is the “correct” way according to the internet authors – is to apply flux and a small piece of solder to the joint that you want to assemble and then heat the part with the soldering iron. Eventually, the part will get so hot that the solder will melt. When, it does, you simply remove the soldering iron. The solder hardens as it quickly cools and the joint is secure.

The second – which is the “incorrect” way – is to apply solder to the soldering iron and “paint” the solder against the joint that you want to assemble. Again, when you remove the soldering iron, the solder hardens as it cools and the joint ends up being secure. Apparently, this is “incorrect” because it can foul your tip and, based on experience, it is less precise.

I tried both approaches both out of curiosity and out of necessity. I definitely prefer the heat-the-part method but I struggled with it. I think I struggled for three reasons. First, I bought a 25-watt soldering iron and had a tough time getting my solder to melt by heating the part. I may want to try a 30- or 45-watt soldering iron in the future. Second, I used silver solder which, as I read later, is more difficult to use than traditional lead solder. It has a higher melting point (which may have been exacerbated by my first point). Third, I had very thin solder which tended to leak between the gap in the joint rather than fill the gap which I had expected/hoped. I think a thicker lead solder may have filled the joint better even after it melted. All of these hypotheses can be put to test later on because I’m excited to try soldering again in the future.

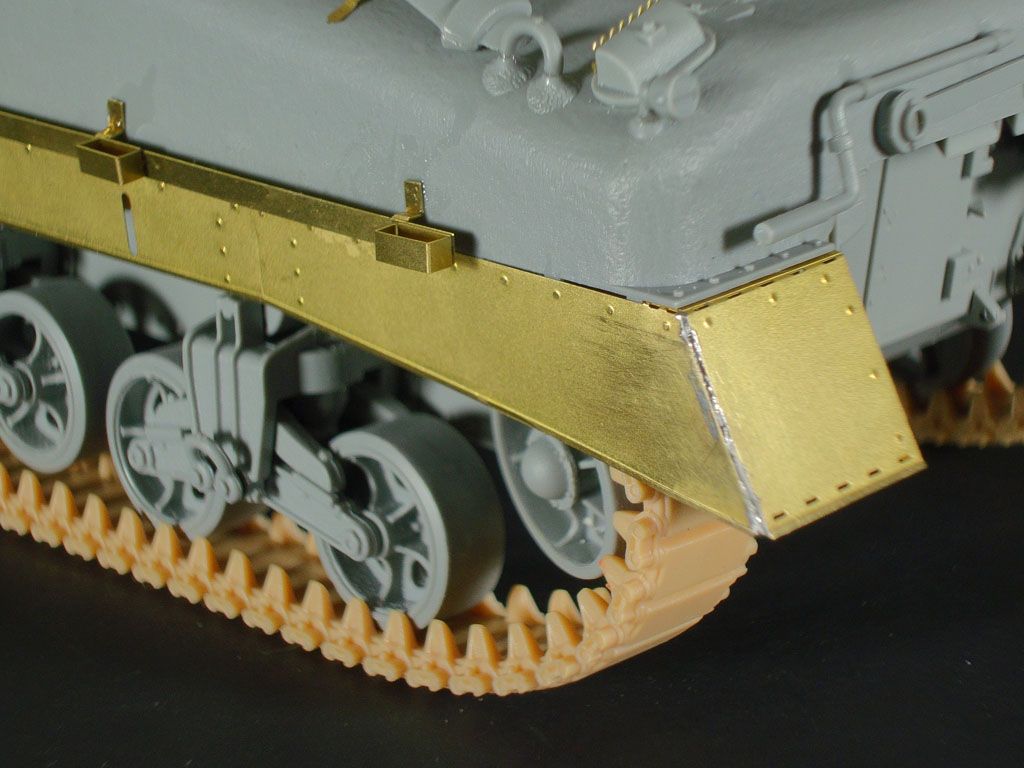

Back to the build: since this was my first time soldering, I started with the rear quarter panels. The shape was square, and the fit was better. So, I figured it would be easier. I was right. I tried each method with the quarter panels with some success. I had quite a bit of solder leak through the joint in my first attempt in which I tried the heat-the-part method. I tried the paint-the-solder approach with the second piece and ended up with a better looking joint but used a lot more solder. Still, the joint was secure and looked pretty good.

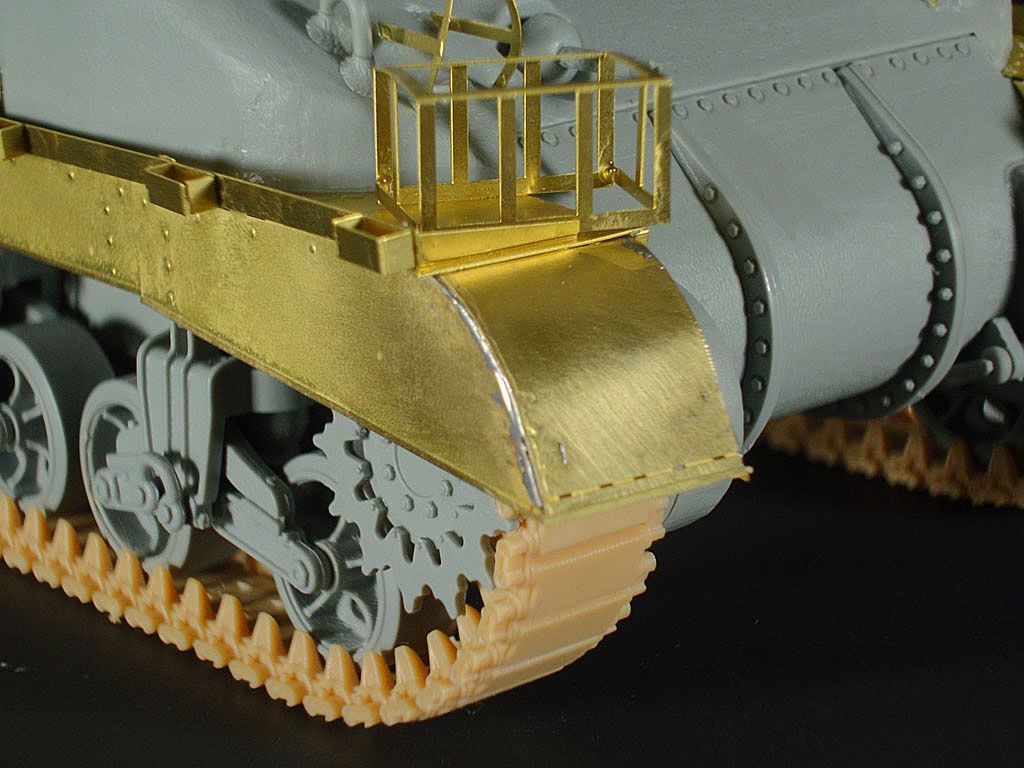

With a little confidence under my belt, I started work on the front fenders. As I mentioned the fenders need to be curved. I ended up taking a dowel and rolling the PE against the dowel to get the approximate shape. Then, I tried to make small adjustments to fit the top, curved piece to the sides. Finally, I took thin strips of low-tack blue tape to hold the part as I wanted it.

The fenders have small tabs which help align everything. I tried to tack down with a small piece of solder. Unfortunately, I couldn’t get it to stay. As I applied more solder and heated the part, the small piece of solder would melt again, and the part would pop apart. In the end, I painted the solder into the joint on both parts. Even this was a trick because as the part heated up, the glue melted on the tape and the joint would pop unless there was some solid solder in critical sections of the joint.

With the soldering done, I used CA to glue small rails/guides to the front fenders that created a horizontal lip to cover the seem between the fenders and the lower hull and to provide a place for the fenders to rest on the hull, providing them with necessary strength.

Next, I glued the three-pieces of each sand shield to the upper hull. The contact point between the PE and the hull is very small. So, to join these parts together, I used small amounts of thin CA to tack each part in place. Then, I applied a liberal amount of thick CA to the underside of the upper hull to strengthen the joint and let it dry.

My two disappointments were:

- The seams between the panels are fairly conspicuous. While I can see similar seam in reference photos, they do not look as pronounced as on my model. In hindsight, I wonder if I should have soldered all three pieces together before attaching them to the model. I chose not to because I was concerned that the three pieces would not fit perfectly but I’m still not sure what the right answer is.

- The front left fender is not squarely attached to the upper hull and appears to dip a little compared with the right one. This is user error and nothing wrong with the kit. And, while this arguably looks like it may be worn and make it more authentic, I would have preferred it to look a little more symmetrical.

Finally, with the sand shields secure, I was able to add the final PE details.

Now, while things look mostly finished, I still have a punch list to which glue needs to be applied:

- the bogies, sprockets and idlers are not glued to the lower hull

- the track is not yet installed

- the lower and upper hulls have not been joined,

- the “a” and “b” antennae for the radio need to be cut and glued in place, and

- I have several periscopes to install.

However, I need to get paint on this bad boy before I stick all that stuff together. So, next time: paint. Can’t wait!