Dan, you are racing along there, good to see the Mustang going so well. You should have 3 or 4 done by year's end!

Trabi, looks like you have a bit of wrangling to get the 154 into shape, but the results are good so far.

Matt, Like the scheme, and especially the touch with salvaged panels.

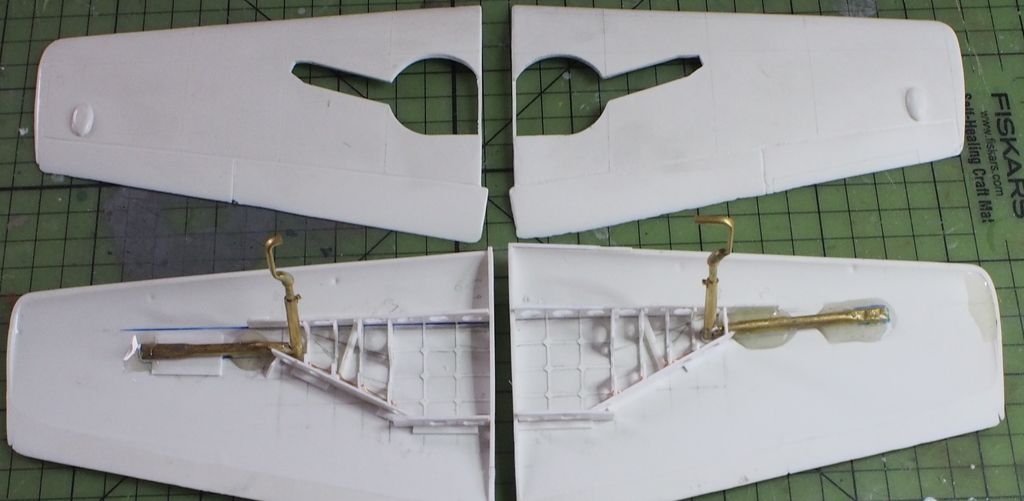

On the MB5 the wheel wells have now been completed, here with the undercarriage sat (not fixed) in place. Managed to break one of the sockets during the fitout, so had to make another one. This time it was much better as I used jeweller's silver solder, should be stronger too. Both sockets were epoxied in place:

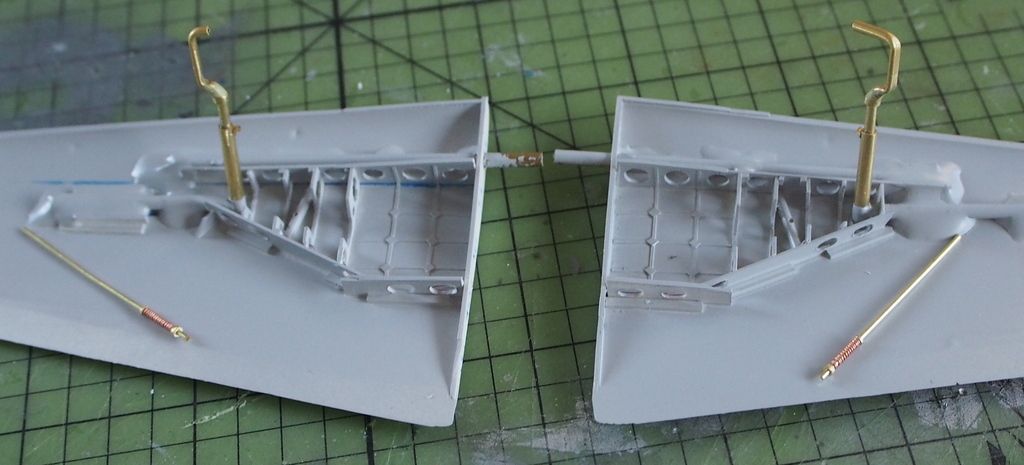

Next the spars were put in to stiffen the wing and give a good attachment. The wings were then primed. Now I have noticed I have not put in the spar details on the wing root internals, have to fix that up. Also in here is the early stage of the retraction mechanism. Last details, painting and then it can be closed up:

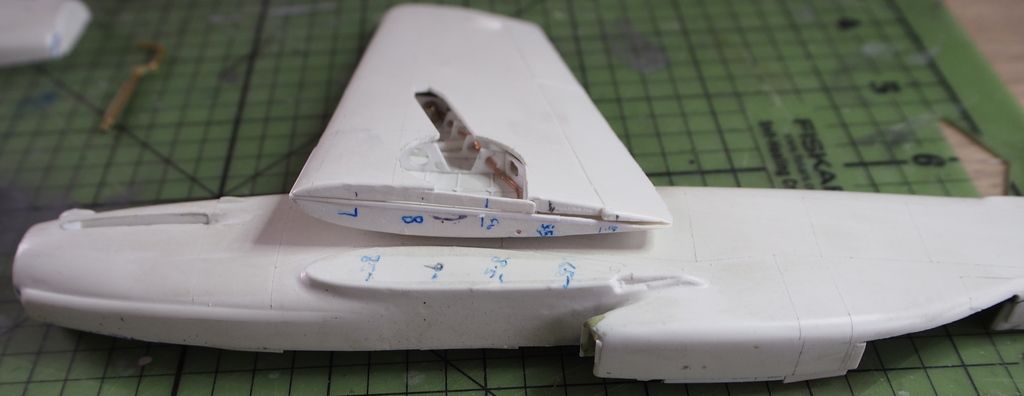

BUT a BIG shout out to Dan and the photo of his work to get the Mustang wings to fit. I thought - that's poor moulding - that could never happen on a vacform...

So I immediately went and measured the wing root and the mating part on the fuselage, and yes they are well out and different on each side. So some shimming has solved the worst of it and the rest willl be dealt with in construction, but thanks Dan, it could have been real ugly.

Also thanks Mustang, that rivet tool is exactly what I need to get all the prominent fastener heads (not rivets) on the MB5 - there are a lot of them. My order is in.