Made a lot of progress today on the little stuff...since this is an open topped vehicle and the interior will be largely visible, I focused on that and skipped around in the steps as a result.

First up was the completion of the items in Step 2. This installs the return roller mounts and final drive housings to the exterior. It also calls for the installation of the idler mounts but I'm leaving that off until later to allow for more flexibility when the time comes to mount the tracks and get the proper position/tension. This step also calls for the installation of the ends of the final drive shafts, something that after I had installed them I think would've been better to wait on due to the way the brake housing and actual shafts install into them, more on that in just a bit.

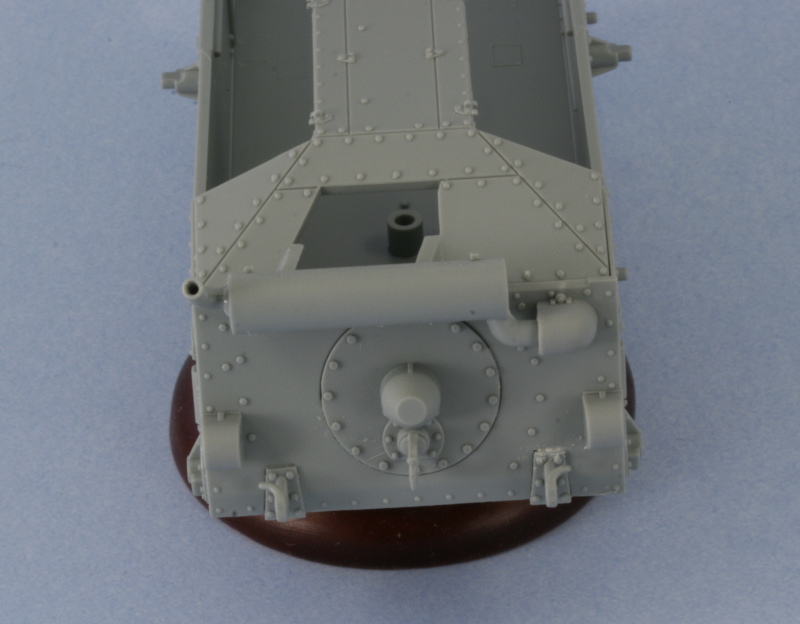

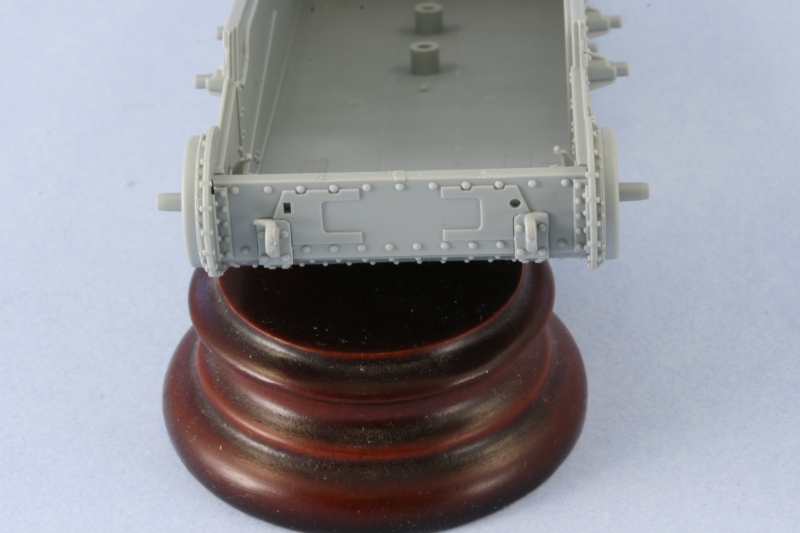

Step 3 deals with the assembly of the rear hull plate details but since the plate itself doesn't get installed to the hull until Step 5, I decided to rearrange things a bit and installed the plate first, then added the details. This proved to be a wise approach especially in regards to the muffler mounts as they have a very small surface area to mount to and it's best done on a stable platform.

The muffler assembly requires a modification to the exhaust pipe to allow it to be positioned at the correct angle instead of vertical and the instructions point out that the pipe needs the tab cut away to do this, easily done with sprue cutters and cleaned up with a #11 knife. The instructions include a helpful diagram to get the pipe aligned at the correct angle and the easiest way to achieve this is to glue the pipe into the muffler then use the diagram like you would any line drawing and rotate it to match the angle. I also enlarged the hole in the pipe with the point of #11 knife as it appeared too small for my liking. The seam from the two part assembly was sanded down and a test fit of the pipe that enters the hull showed the hole in the hull was too small...so I used a round needle file to enlarge it to the right diameter. The armored cover also required some adjustment with the needle file to have sufficient clearance to mount flush to the hull.

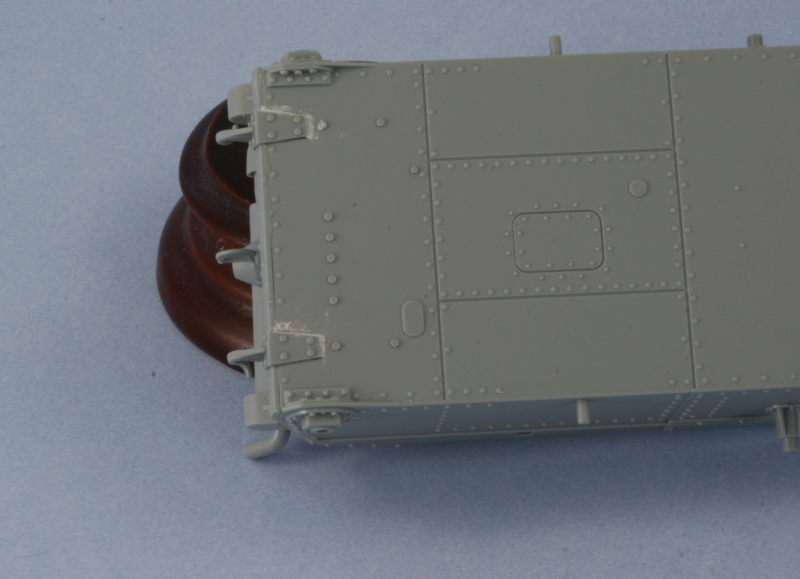

The rest of the details were added, the step gives you the option of armored or unarmored idler covers but only the armored are appropriate. An option is provided for the tow hitch and I chose the one with the rectangular latch vs. the open hook based on reference photos. The armored cover was added to the round transmission hatch and the rear tow hooks installed. Some putty was required to fill gaps on the molded in slots, more on the bottom than on the top. The tow hooks also had to have their tabs trimmed down as they were too large to fit the cutouts provided.

Step 4 deals with the fenders and I skipped that for now but will come back to it shortly. Step 5 calls for the installation of the rear hull plate (already done) and the fenders, so it too was skipped. It's important to note that this step shows the driver's knee pad already installed on the right hull side but doesn't have a part number assigned to it. It's A17 and I will paint and install that separately. This is an error/oversight on DML's part in the instructions and is an easy one to miss if you aren't paying attention.

I skipped over Step 6 since that installs the suspension and I'm not ready to do that just yet. Step 7 deals with the interior details beginning with the brake housing and transmission. The brake housing is only visible if you elect to have the glacis hatch open but it's still a necessary component to get the transmission and drive-shaft placed properly. Because the end mounts were installed in Step 2, it's imperative that you DO NOT glue parts D46 into the brake housing at this step...if you do, you cannot install the brake housing in place because there isn't enough clearance to achieve that. Parts D46 have a d-shaped end that must be perfectly aligned with the ends in the hull...so I left them off for now. I opted for the styrene version of the driver's controls and assembled and attached the transmission and drive shaft. The drive shaft is a little loose on the transmission square peg so I used the rear bulkhead dry-fit to help it set up in the proper position and alignment.

Also included in this step is the driver's seat. I must say I'm extremely disappointed in this area...the seat mount is 100% wrong...and it's something DML has known about since this came off the 38t G sprue and yet they've perpetuated it into this kit. Probably too expensive to correct the entire sprue mold, but that doesn't excuse the fact that the mount is pure fantasy. The seat itself is also very inaccurate...it doesn't have a cushion for the bottom but does provide one for the top. There are no straps for that cushion on the back portion of the rest but they do replicate the ratchet details for the seat adjuster correctly...go figure.

Step 7 also calls for the assembly of the front hull plate. As with the rear hull plate, it's easier to install the plate first and then add details to it. The mounts for the tow hooks were installed first and, just as with the rear, the hooks needed their tabs trimmed down to fit properly.

The next little interior detail was the racks for the K98 rifles...there are two and are a combination of styrene and PE parts. The bases are styrene and mold locator lines are provided in the lower hull. The are locator lines for the PE top portions as well...but the kit doesn't provide any rifles. I scrounged around in my spares bin and located a pair, with some careful gymnastics, the rifles can be taken in and out of the racks so they will be painted separately and then installed. These racks aren't called out in the instructions until Step 18 and it's much easier to install them now rather than wait until then when there's a lot more in the way and a whole lot less room to maneuver the rifles.

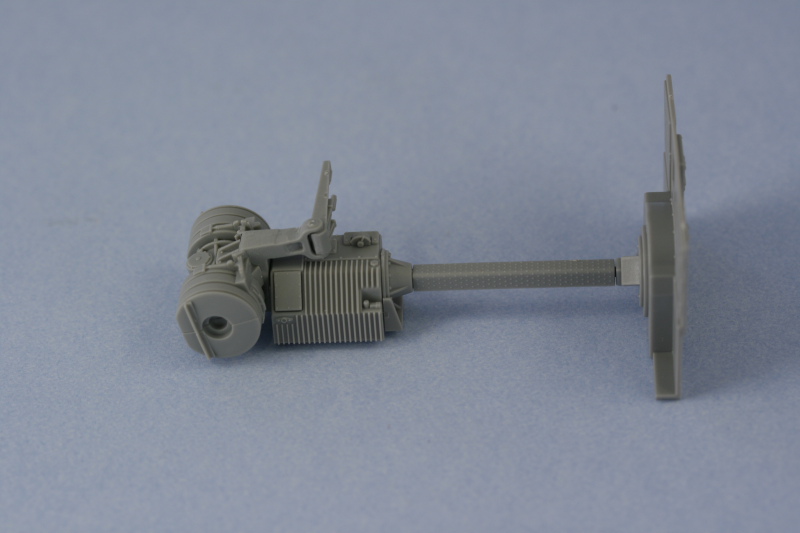

Another interior detail got attention at this point, the pedestal mount for the sIG 33. This is also called out in Step 18 but I went ahead and assembled it now so it could be painted before installation. The choice is provided for either the stacked stair-step style mount or simple I-beam mounts, I opted for the stair-step style. The assembly is a delicate one as the bases are free standing and the only thing holding them together is the pyramid shaped top portion...which is attached to two small base pieces in turn. I made sure to assemble this on a level surface and insured the bases were square as this is an integral piece for mounting the gun.

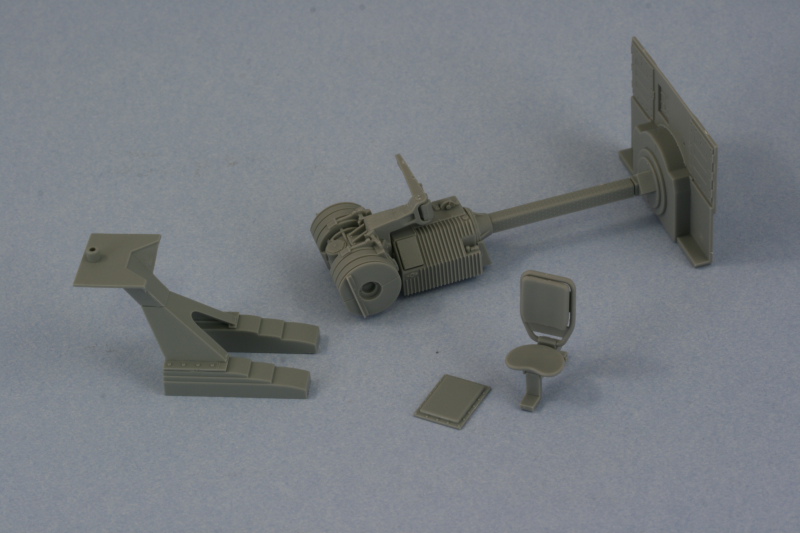

These are all the separate interior pieces assembled today...they will be painted separately from the lower hull and then installed after they've been detailed.

Total Session Time: 6 hours

Total Time to Date: 8.5 hours