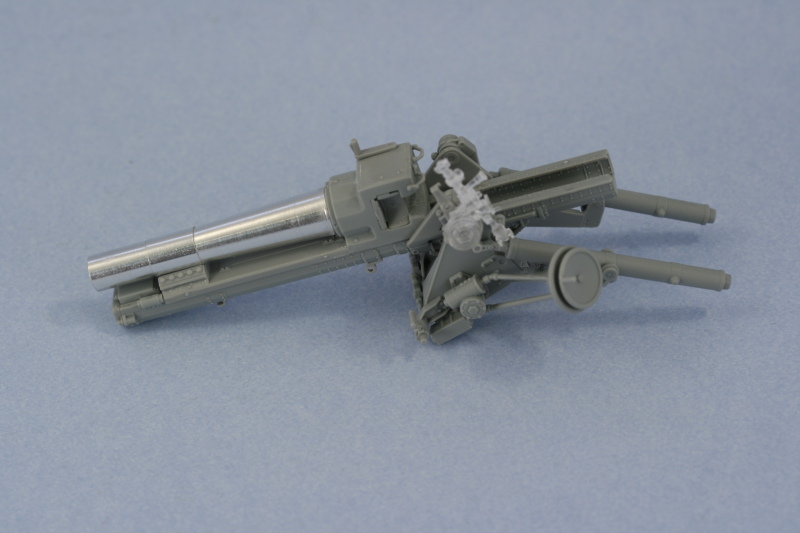

Since I will be out of town this weekend, I decided to get in as much time as I could squeeze in here and there to at least get the final pre-paint steps done. The biggest item of business was the sIG 33 gun, so work began there in Step 21. The step calls for assembly of the breech block first and has two halves for the breech and 4 parts for the sliding block. The instructions are a little vague when it comes to part B14 and indicates that you should glue this directly to the sliding block part B5...but I found it was better to glue it into the assembled block halves and leave the sliding block able to move freely. The assembly uses an insert for the top of the block to avoid a large seam but some sanding was still necessary around its edges to get a seamless look. The same was true of the interior of the two halves which I carefully sanded with a round needle file to avoid damaging the detail there.

The second portion of the step adds the front part of the recoil sled along with the aluminum barrel. I added the recoil sled portion first so that it would have a solid/level connection with the breech block and let that dry. The small join with the block was lightly sanded and then the barrel added using CA gel at the base as well as the front where the barrel hoop attaches to the sled.

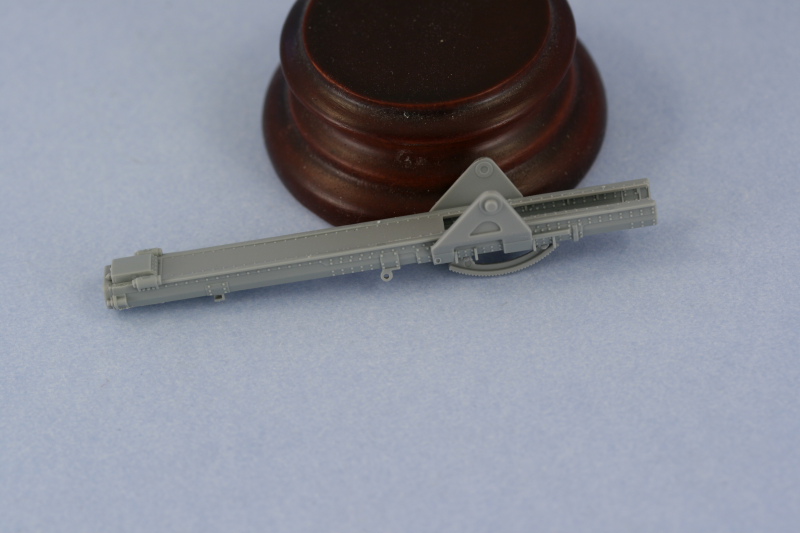

Next came the gun mount and tray in Step 22 and 23. This is a complex step with a lot of sub-diagrams, so you need to decide your angle of attack first. I started with the tray, which assembles out of 3 parts to avoid the longitudinal seam common in other kits. The contact surfaces for this approach are small though, so I glued the bottom piece first to one side using regular glue and then repeated for the other side once the glue had set up a little. I used the recoil sled from the previous step to test-fit and make sure the width was correct. Then I added the insert that completes the top portion of the tray using liquid glue to get it to align properly since the thin rear portions in particular needed to be aligned very carefully. The two small grab bars on the breech block were also added...a feature that wasn't always present on sIG 33 guns but which matches the style of this particular one that DML included.

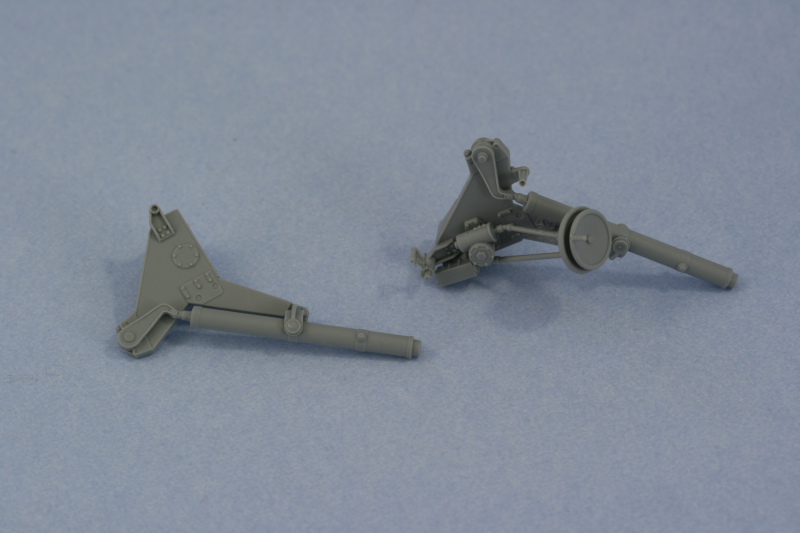

Next up were the two halves of the mount and the recoil cylinders. The right side of the mount is pretty simple while the left one is more complex since it also includes the elevation gears and gun sight. The sub-assembly diagrams for the elevation gears asks for a nearly impossible construction sequence where you add the different components to the wheel box and then install to the side of the mount. I ignored this except for the parts number call-outs and instead installed the two different gear elements, parts C13 and C7, into their proper positions on the mount side first. Then I added the gear box C10 and it's connection conduit part C6 to insure the proper alignment and fit of all the parts. Last but not least the hand wheels were then added.

Everything was then brought together to complete the mount assembly. The instructions do not tell you this, but if you don't glue the tops of parts F46 and F47 to the trunnion points on the recoil tray, the gun can remain positionable for later installation. If you do glue them into position, be sure you've got the right elevation set or you'll be stuck otherwise. I also assembled the gun sight, opting for the short neck version since the Grille H has a cut-out in the front superstructure whereas the long neck is more common on the Grille M and Bison I that didn't have that type of cutout available. The elevation arms on the gradient gear had two small holes molded into them, these are not ejector marks but should be there however DML didn't mold them all the way open for some reason...so this was cured using a pin vise and drill bit.

I've left the recoil sled and gun dry fit for now to facilitate detail painting later on...it's a very tight fight as is, so no glue is actually required unless you choose to use it for a permanent join.

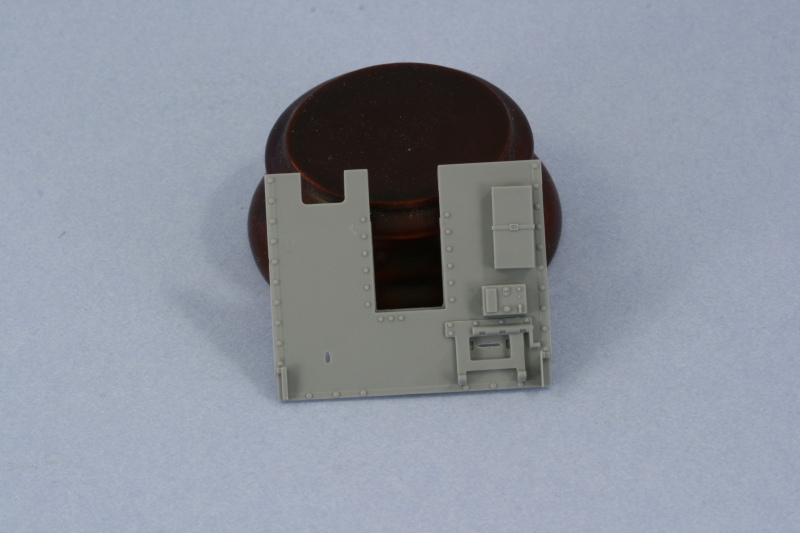

Returning back to Step 19, I added the details to the interior and exterior of the front superstructure plate. The driver's visor had a very tiny slit molded into it, so I opened this up a bit more using the tip of a needle file and then cleaned it up with a #11 blade. No armored glass block is provided for, I'm not sure if one was supposed to be fitted or not on this particular vehicle but it seems strange for it to be absent.

Details were also added to the front of the superstructure plate and a word of warning is appropriate here. The diagrams direct the installation of the sliding heavy additional front plate, part F60, and it's spring-loaded hinged plate F69 in the position that's appropriate for the gun in the travel level elevation position. If you decide to pose the gun in an elevated or firing position, you will need to adjust the position of both parts, not just the spring-loaded hinged part. I'm going to have mine in the level position and may or may not engage the lock, so that's not a problem for me but it is a trap for the unwary if you're doing a dio or similar where you decide on something different elevation-wise.

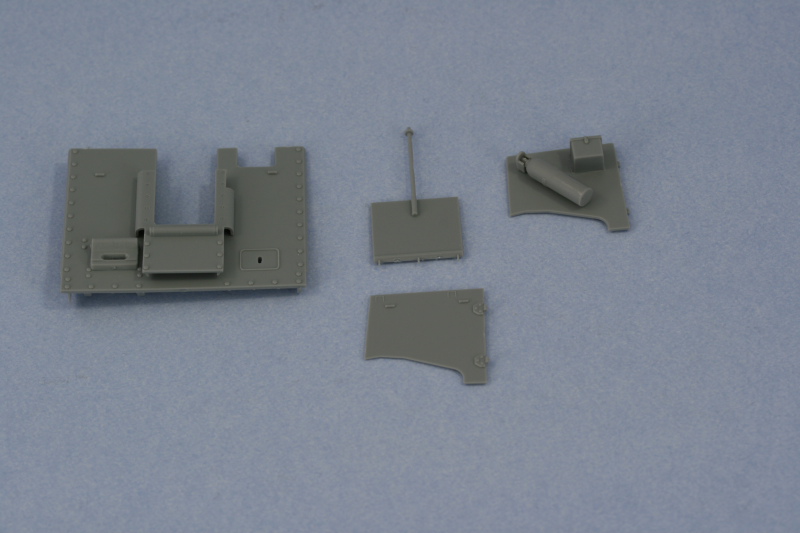

I also cleaned up the rear compartment doors and installed the fire extinguisher and small box to the left door. The rear fixed panel received the canvas cover pole while the right door was cleaned up in preparation for paint and didn't have any parts required.

That's all the construction that will be completed before the superstructure interior is painted.

Total Session Time: 4.5 hours

Total Time to Date: 32.75 hours