Building on yesterday's foundational paint work, today was all about painting and installing the various details. I spent virtually the whole day painting and detailing items and it was only as I got to the end of the session that things finally started to get installed.

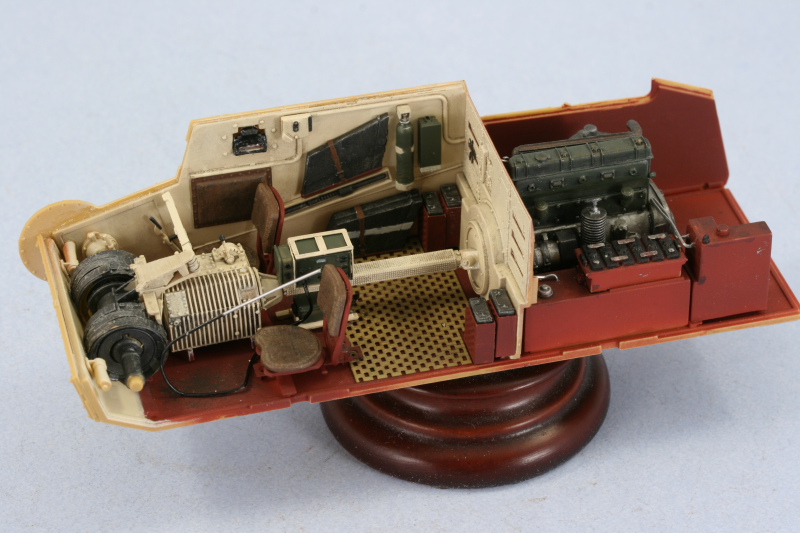

The first set of details to get installed were on the driver's side. I added the crash pad, the signal staff, main gun ammo can, and fire extinguisher after hand painting them prior to installation. The Interior Set neglected to provide a first aid kit that is supposed to be next to the FE, so I scrounged around in my spare PE fret bin until I found a box shape of suitable size/dimensions to use. I used the old artist trick of "trompe leoil" by painting in the "rack" that it's supposed to be sitting in on the base so it looks like it has a holder. I applied a wash of Raw Umber to weather the elfenbein and then dry brushed some of the enamel Panzer Interior Buff over that to blend it back in and give it a slightly grungy look.

The radio operator's side got a similar treatment and the two ammunition holders were installed. Getting them into the right position required a careful check of my interior reference photos in PT-13 since the Tristar Interior Set instructions are vague at best as to their exact placement. Since they have to clear the MG ammo bins attached to the firewall and the radio operator's seat, the tolerances are very tight with no room for error. To insure I got them in the right position, I used the masking tape trick again to hold the hull side to the floor with the firewall dry fit in position and then carefully glued the racks in place with CA gel. The white stripe on some of the ammo cans is something that shows up in the PT 13 interior photos, my guess is that it distinguishes between HE and AP rounds but I can't be sure. I added the stripe using masking tape and careful application of Light Gray by brush.

Next up was the transmission/brake housing/drive shaft. Even though the brake housing won't be seen, I still painted it up just to be sure that there wouldn't be any bare plastic viewable. The transmission was given a wash of Raw Umber and then dry brushed just like the hull sides. The Interior Set provides two different radio sets but since this is a normal vehicle and not a command tank, I only used part H48 for the receiver that a standard tank would be equipped with. PT 13 indicates in the text that the receiver was mounted to the drive shaft so it was positioned that way deliberately. The Tristar Interior Set instructions don't provide any advice/help at all on where the radio is supposed to go since it's a generic set meant for any of Tristar's 38(t) vehicles including the command variants. I also wired it up with some 1mm diameter solder that will connect up to the antenna pot on the hull front plate once that's installed.

I also painted and installed the seat cushions for both crew positions. The driver's cushions had to be adjusted slightly to clear both the hull side and the transmission while the radio operator's went on just fine with no issues. The MG bins were added to the firewall and then the flooring for the area below the turret added to get it aligned properly. The transformer for the radio receiver was added, the rack for which I cut down since it was designed to hold transformers for both a transmitter and receiver. It too was wired up so that it could be connected to the receiver once it was installed. The double ammo bins for the driver's side were detailed and installed with the outer can receiving a white stripe as well. I also weathered the exposed floor areas with dry brushed Steel and Burnt Umber but I don't think very much of it will be visible in the end...but at least I know it's there!

The superstructure front plate also received some attention. It received the same wash and dry brush treatment as the rest of the interior and the driver's periscope was detailed with Flat Black and the green-red-blue signal lights added using regular Testors enamel Beret Green, Flat Red, and Sea Blue. The MG will get added later once the plate is installed to avoid the possibility of damaging it.

With all that taken care of, Franklin needed to start getting assembly...so the driver's side was added first to the floor using regular glue and finger pressure to get a good join.

Same thing was repeated for the radio operator's side.

The final act for the day was to add the glacis plate and the rear hull plate to insure that the hull sides were lining up properly. The glacis plate required the use of some rubber bands to get it to sit down flush at the front due to the fact that it needed to align in three different directions to sit at the right angle. After about 15 minutes the bands came off and the hull was together.

Next up will be working on the turret details and then it will be time to do some cutting and fitting of the remaining external details.