Hope everyone had a great Labor Day holiday! Efforts today certainly lived up to the 'labor' part at least but I had fun working on the main mast and its components.

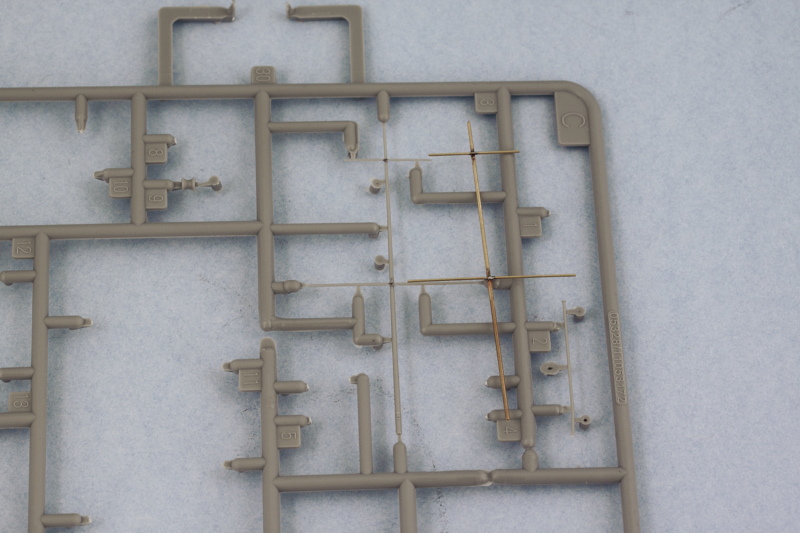

I decided to replace the kit-supplied styrene mast-crossarm piece, C3, with brass rod to provide added strength and durability for this critical piece of the superstructure. My LHS stocks several different diameters of brass rod in their R/C aircraft section and I picked out different lengths of varying diameters and brought them home to see which would do the trick since the cross arms are thinner than the mast itself. I used a Dremel cordless tool and a cone-shaped grinder tool to introduce a taper for the mast but left the cross arms as-is given their relative thinness to begin with. Once I had the main mast done, I cut out the three cross arms again using the kit part as a guide for their length, and then marked their center points with a sharpie. Using a triangular needle file, I notched the main mast in the appropriate places so the cross arms would have a solid contact point.

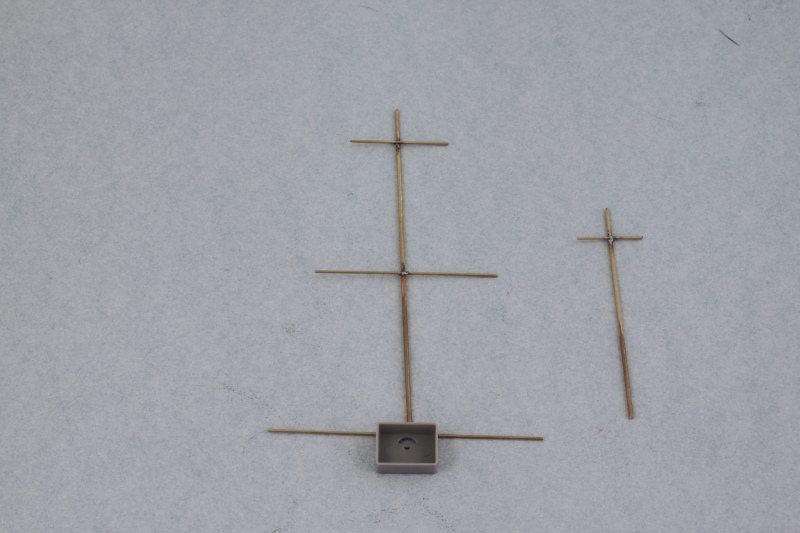

Once all that prep work was done, it was time to solder the cross arms to the mast. I have a Weller variable temp soldering iron and while it was warming up, I used a piece of fiber board and some T-pins to position the mast and cross arms correctly. I used silver-bearing solder paste to place small beads over the join, the soldering iron provided the heat, and voilà! Brass mast and cross arms.

While I was at it, I also created the rear mast and cross arm combo for the aft mast. The third cross arm for the main mast integrates directly with the fire direction platform, so it was secured in place with CA gel separately from the main mast. This also makes life easier when attaching all the PE bits for the underside as the cross arm becomes a convenient 'handle'.

Speaking of PE, the next steps require lots of patience and test fitting with the tripod to make sure the alignment is correct on all the underside supports for the fire direction platform. There are 5 separate parts and the locater marks that Trumpeter provides are a helpful guide but some adjustments are still needed to get the parts to line up correctly and play nice.

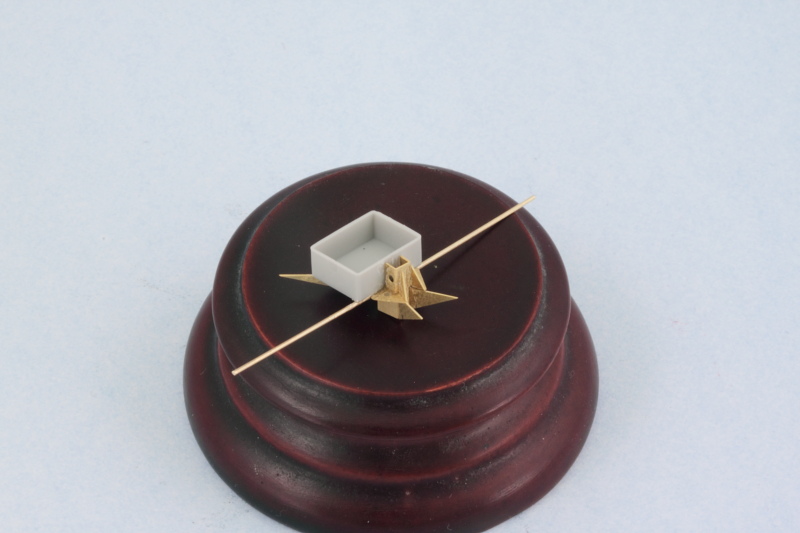

If using the styrene masts, Trumpeter has you secure the mast to the platform before adding the rear bracket and rigging extensions. I did the reverse for handling reasons due to the added weight of the brass masts and also to create an added support structure for the mast itself. The rear bracket is made up of 5 different PE parts that all have to come together just so to create the right effect and the Trumpeter instructions aren't super clear on how they all come together. Fortunately the Kagero 3D book includes a very nice look at this area and helped greatly in terms of getting it all lined up properly.

With that done, it was time to pair up the mast and cross arms with the platform. I flattened the rod with a square file so it could have a greater contact surface with the back of the platform and used CA gel to give me a little work time to ensure it was positioned at the right height and alignment with the third cross arm. Once the CA gel had grabbed hold, I used some Aves epoxy putty to stuff the base of the rear clamp structure so it would provide some greater stability and hold for the mast over the long term. A dry-fit test shows everything is lining up properly even though the angle on the camera isn't quite perpendicular.

Not a bad day's work, the second mast should go faster now that I've learned the 'tricks' of the PE from doing the first one.