Sherman II at El Alamein: Construction (Upper Hull)

Let’s pickup with my build of Dragon Model’s El Alamein Sherman with the upper hull. Ultimately, construction involves adding detail – lots of it – to the one-piece upper hull.

The instructions provide two steps in which dozens of small plastic and photo-etch parts are installed. Interestingly, these are steps 5 and 7. Step 6 has you building the commander’s hatch for the turret but turret construction doesn’t really start until step 8. So, for now, I’m going to skip step 6 and just focus on the upper hull.

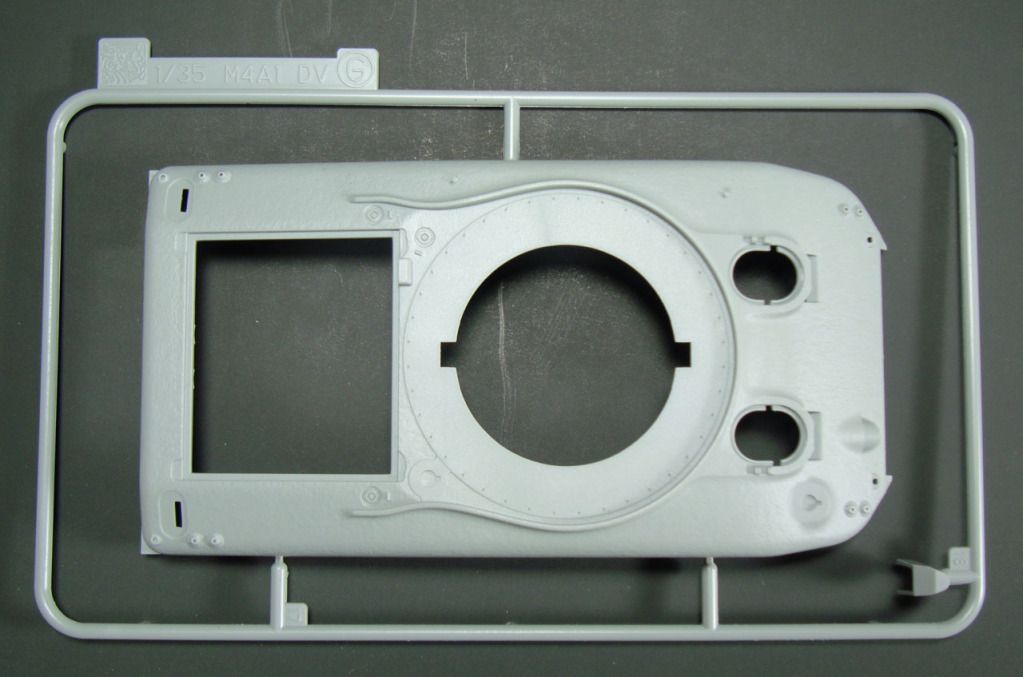

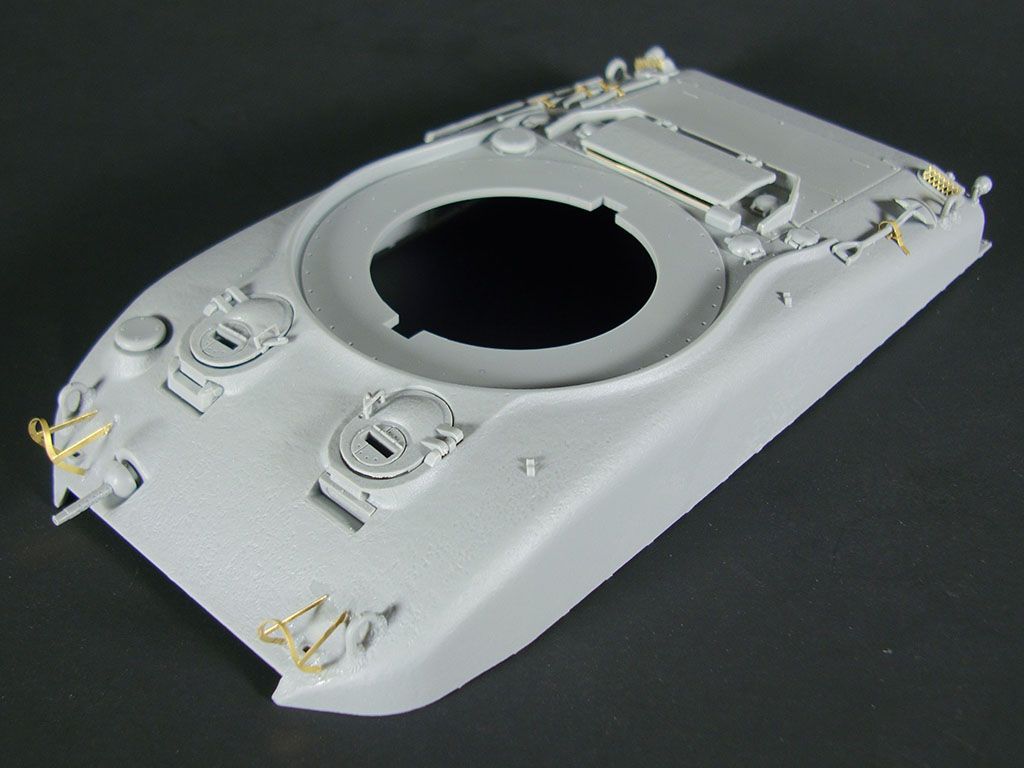

The upper hull itself comes mounted on a sprue with three attachment points. I carefully scraped and sanded the nubs left by these attachment points so that I would not hurt the cast iron effects molded on the hull. While the hubs are still visible, they should be hidden by the photo-etch sand shields that will be installed later.

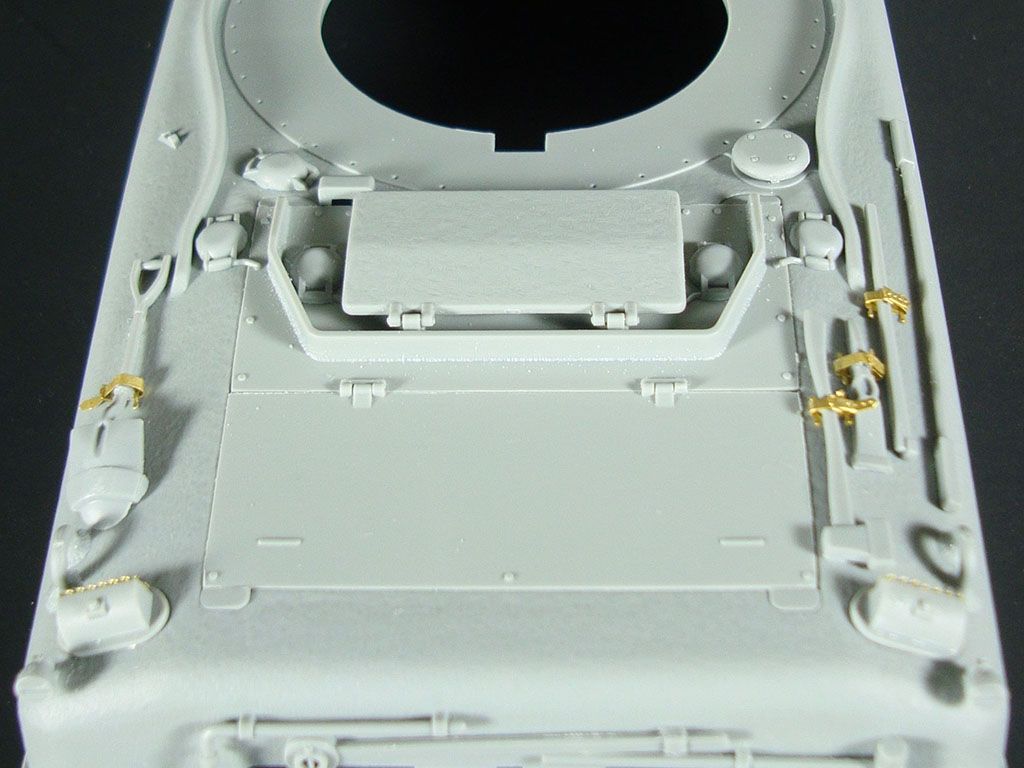

I started my work with the driver and assistant driver’s hatches. These consist of five parts each, including a clear periscope. Due to their small size and difficulty masking them, I chose to leave the periscopes and their covers off for the time being. I decided to use the kit provided hand grabs as they seemed to scale and I was able to successfully clean up the small parts without breaking them. (Please note, the hatches are not attached, yet. I’ve just positioned them in place for the picture below.)

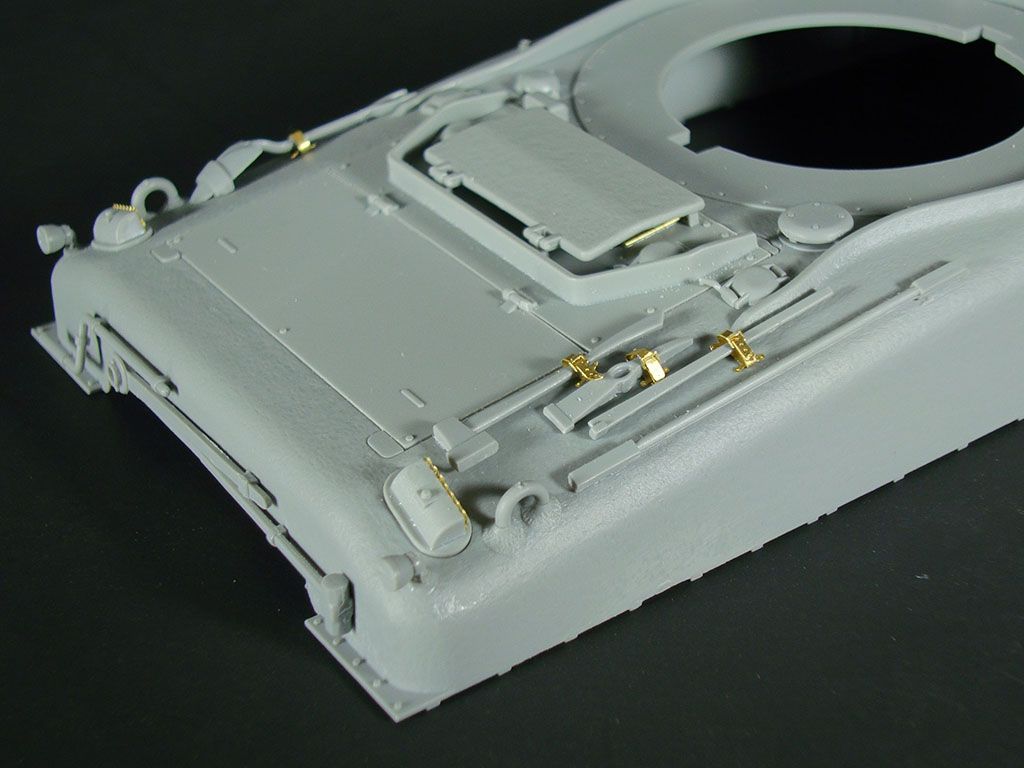

Next, I built the rear panel. This consists of two large pieces of plastic which represent the engine cover, a small photo etch screen (not visible in the picture below), plastic cover for the screen and a few small caps/covers. Unfortunately, I was too aggressive my sanding one of the panels, taking the panel out of square. I considered replacing it with plastic card but after test fitting it, the mistake was not too noticeable.

At this point, I also added the exhaust pipes, tail lights, and two vents with photo-etch screens to the rear of the tank. Dragon gives you options for these vents: rounded and angled. Each version has its own photo etch. I decided to use the rounded vents as I didn’t see any reference photos of the other but, while I chose the rounded vents, I found the angled screen fit best. Go figure.

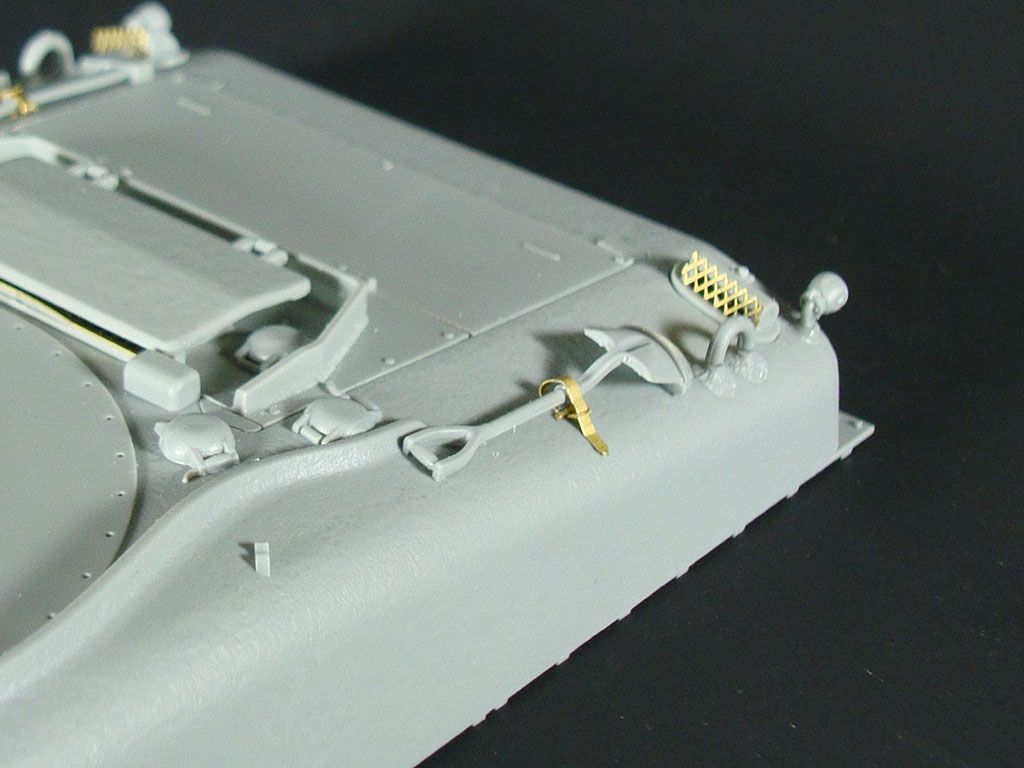

With most of the plastic attached to the upper hull, I now had to muster the courage to install the photo etch headlight guards. This requires curving a flat piece of photo etch into the shape of the guard and attaching it to the front of the upper hull.

Dragon provides a jig to help you get the right shape. The jig includes a small ridge. By lining up the piece with the ridge, enough PE will be exposed on the back of the jig to attached it to the model. Unfortunately, the ridge was too shallow and my fingers too stubby to make this work effectively. Still, the jig was useful to get the correct rounded shape.

The next challenge was getting the glue to set while I held the curved piece and jig against the model. After several tries with small amounts of thin cyanoacrylate, I eventually used thick CA with an accelerant to bond the PE to the plastic.

Finally, I turned my attention to the tools. There are several tools mounted to the back of the Sherman II. The tools are nicely molded but several have locator pins on them. Since the upper hull in this kit does not have any locator holes, I removed the pins before getting into the fun stuff.

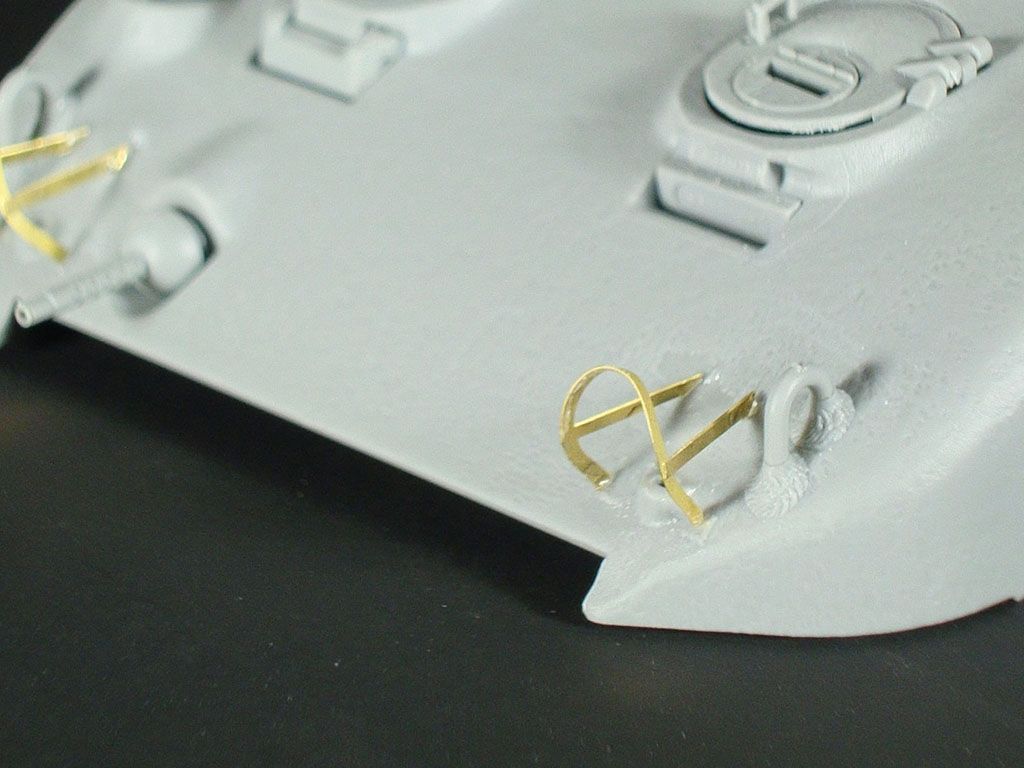

The instructions call for four of the tools to have photo-etch straps attached to them. Each strap has two small PE parts that mimic the bolts that hold the strap to the tank. The directions are not particularly clear. I found a nice blog of another El Alamein Sherman build. After examining his pictures, I eventually figured out how to wrap the PE strap loosely around the tool and mount it with thin CA, pinch the sides of each strap and slide a small hanger into each pinched-corner. These hangers were also glued with thin CA.

Once the PE straps were on the tools, I attached all the tools to the hull using plastic cement for plastic-on-plastic contact and thin CA to attach the PE to the hull.

At this stage, I’m happy with my project. While there are lots of parts, the kit has really gone together well and it has been rewarding to see how my skills have improved since I built the USS Marsh last winter.

In the next post, I’ll construct the turret before turning my attention to final assembly and the piece de résistance of this kit: the large, photo-etch sand shields.