Hi Indy,

OK, you have shamed me into posting a progress report. Nothing as glamorous as the fenders I hewed out of the very living rock....uh, wait, I mean that I folded out of sheet brass and bent a bit.

Against my nature, i bring you a words only update, no photos. I took a few, mind you, but last night got away from me and I didn't get a chance, here we go

This was a non "sexy" progress week.

My former experience with black “magic” tracks has led me in a quest away from those freakishly difficult items which are really the only part of the hobby I do not like. I read the tutorials, they made sense to me, and I followed them to the letter, twice. Both times I had a disaster, separations, weird kinks in the track runs, too short, too long, cursing, sweating, it was not cool. At all. Then I did it again. And it was nasty AGAIN.

First I fled to model kastens, after seeing our own WBill use them with such success. These were far better than the type whose name shall not be spoken, but were still super fragile.

Enter Fruils. Pure, pot metal karmic perfection. METAL! Held together with METAL!! I grabbed a set for my IS3, they are HUGE, heavy, appear to sag realistically, they are tough, it’s everything I ever dreamed of. BTW, I only assembled the IS3s, I haven’t even started on that model yet, let alone weathered the tracks.

(To those kind souls who will chime in that I could get another whole kit for the price of Fruils, those who know me know I am a frugal shopper, I got both a KV-1/and a KV-2 last week, delivered, for $40.00, I am a cheap boy. But if I have to use magic tracks, I am out of this hobby, it is truly that bad for me. It’s as simple as that. I am not kidding)

So naturally, when the rubber band tracks on this tractor appeared as featureless as, well, rubber bands, I did some homework and determined that this tractor has Vickers tank running gear. Fruil makes Vickers/T26 tracks, so I grabbed some.

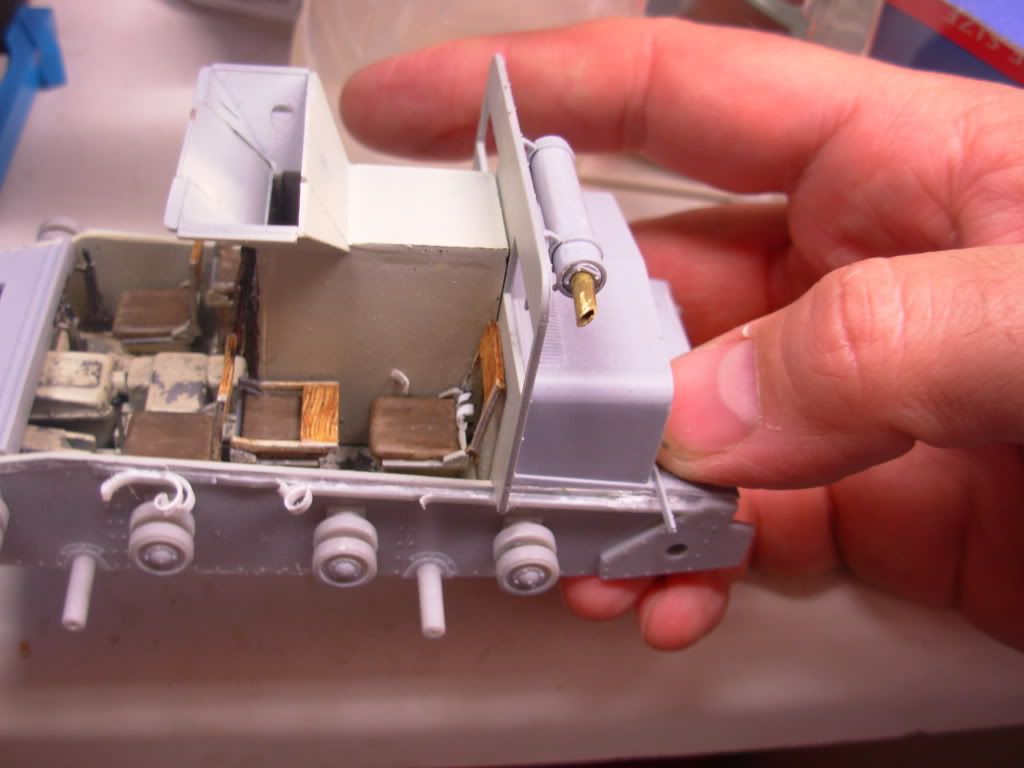

Let me start with the relative difference between an IS3 and this tractor thing. Look at this thing in my hands in this thread. It is TINY.  How did it not occur to me that the fruils would be TINY? They replace the rubber band tracks, those would seem to indicate to any rational person that the tracks are small.

How did it not occur to me that the fruils would be TINY? They replace the rubber band tracks, those would seem to indicate to any rational person that the tracks are small.

So I guess a direct effect of the tiny tracks is the fact that I had to DRILL OUT every single pin hole. Not most, not a lot, but all. For the IS3, I chased maybe 6 holes, and did so by simply punching through with a bit. On these jeweler grade delicate tracks, I had to drill the holes because if they weren’t drilled, the bit would rip the channel open and it would go into the discard pile.

4 days of 1-3 hour sessions with my Optivisor and my thinnest drill bit, first one whole track run, then the next, I though it would never end, but it finally did Friday night. Saturday morning, I started my patented “substitute .020 brass wire instead of the stainless wire because someone told me is worked better” routine. It took forever, but, working between family obligations, I got two track runs done by Sunday evening. Then I washed them down with some dish soap,

and scrubbed them with e toothbrush

then I tossed them in a tub with some heated white vinegar, and let them sit for two hours.

I was going to Blacken it them, but by then it was 2300 on a school night, so I had to hit the bunk.

My plan is a single 10 minute or so application, followed by touch up with a brush to get the substance into any nooks and crannies that I miss with the first go around. I understand that two applications approaches black, which I think will look too dark.

Thanks for checking on me, Indy.