I started building this model by setting up the initial scene in Blender:

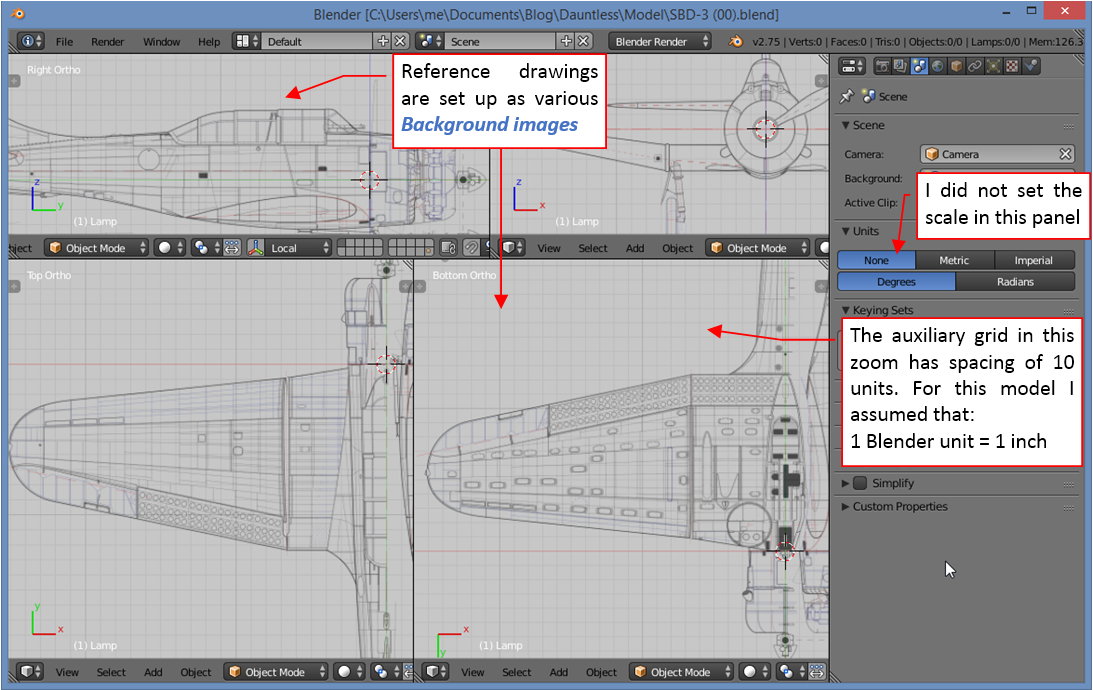

Although Blender allows for arranging the reference drawings on the three perpendicular planes like in the 3D Max, I prefer the alternate way: the Background images feature. Using them, I can assign appropriate image to the corresponding view, and simultaneously use all the six views (bottom, top, left, right, front, rear). They appear just when I set appropriate projection.

This is also the moment to determine the “scale” of this model. Because on the SBD drawings that I have all the dimensions are in inches, I decided to assume that 1 unit in this Blender scene = 1 inch on the real airplane. However, I have no experience with the Blender Units setting, so I left them set to None. If you want to check details of this setup, here is the original *.blend file.

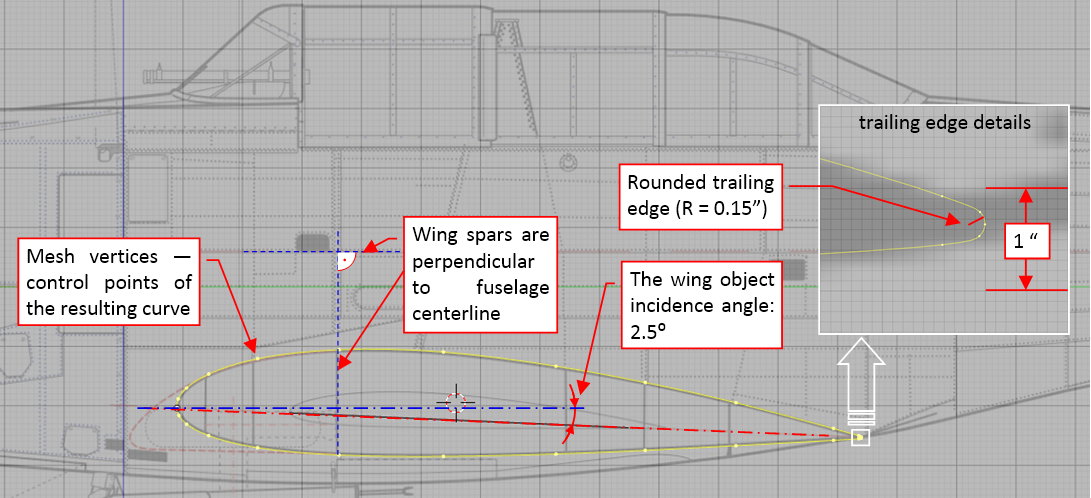

I started modeling the wing by forming the contour of its root rib. (For this purpose I draw the shape NACA2415 airfoil on the reference drawing). I smooth most of the model meshes with Subdivision Surface modifier (it uses the classic Catmull-Clark scheme). The shape of a single edge loop smoothed by this scheme is a piecewise Bezier curve (or, if you wish, a NURBS curve – this is just an alternate math representation). The edge vertices are its control points, so I can easily shape this contour. You can see the result in teh figure below. (In this image you can see that the vertices lie on the rib contour, because the mesh drawing mode there was switched to draw the resulting surface):

The theoretical shape of the NACA-2415 airfoil has a thin, sharp trailing edge. However, in the real airplane it was rounded because of the technological reasons. I tried to determine its radius from the photos. As you can see in the enlarged fragment of the picture above, it forms a small wedge with rounded corner. It is shaped using five vertices. (Their number corresponds the number of the leading edge vertices — I will explain the reason further in this text). The Dauntless inherited many solutions from its Northrop Delta lineage. For example — its wing spars are not perpendicular to the wing airfoil chord. Instead, they are perpendicular to the fuselage centerline. (In the SBD, like in the earlier Northrop designs, the center wing panel and the fuselage form a single unit. I suppose that it was easier to put together the wing spars and fuselage bulkheads when they shared the same technological bases).

To provide as many “technological bases” for my model as possible, the X axis of the wing object is parallel to the wing chord. I can set it “in the Northrop way” by setting the object incidence angle to 2.5⁰. In this position I can work with the wing mesh, moving vertices along the global coordinate axes (i.e. the axes of the fuselage), and then switch to the local wing object axes when needed.

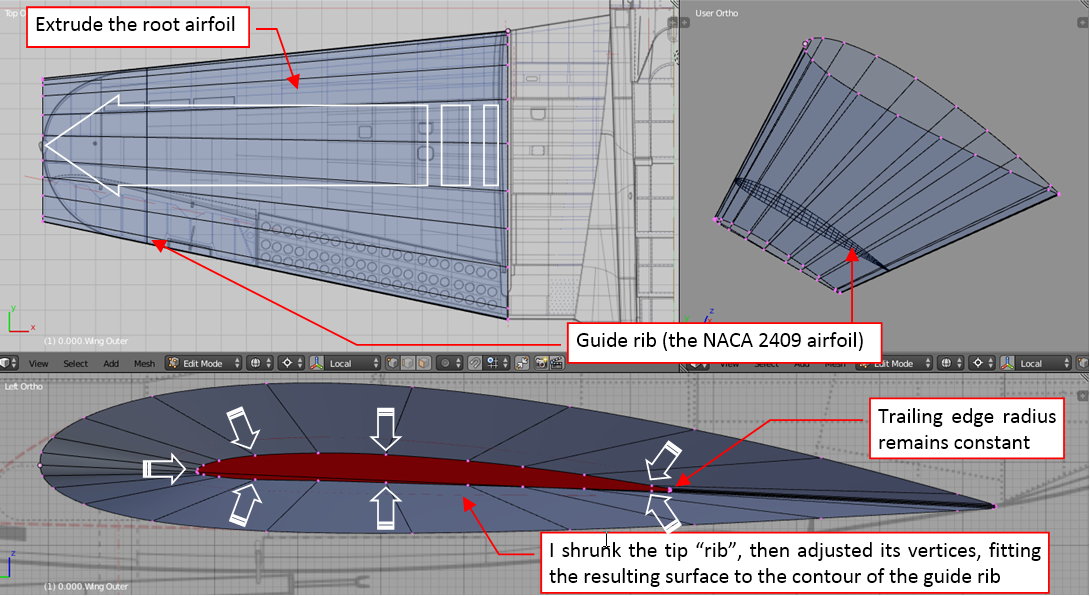

In the next step I formed the basic wing trapeze. I did it by extruding the wing root edge, and shrinking the airfoil located at the wing ti:

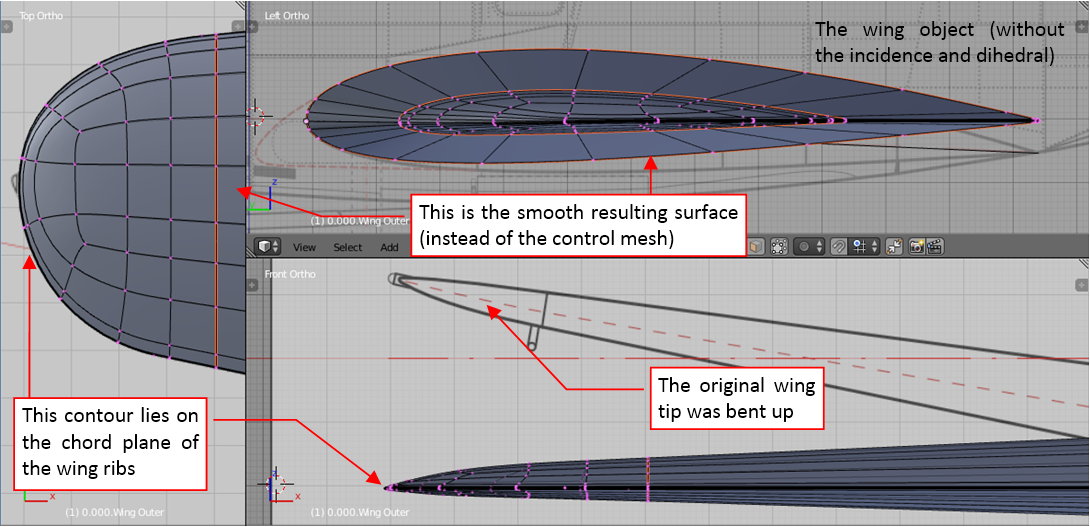

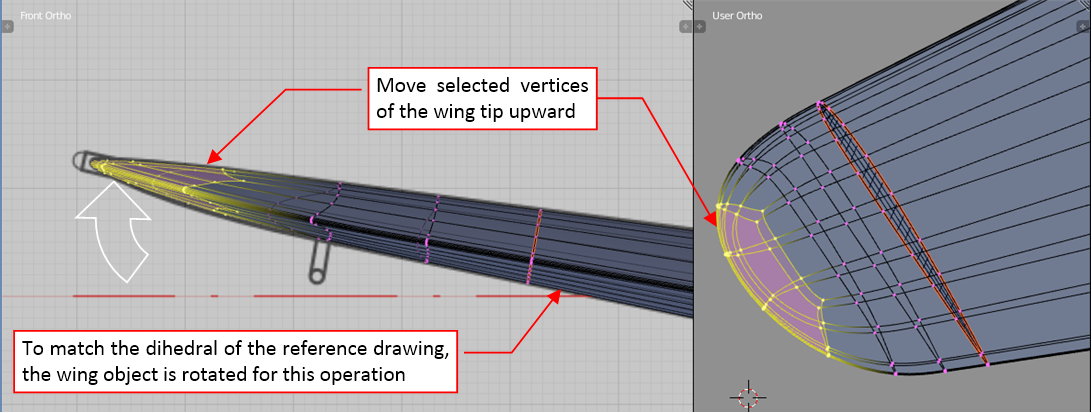

Now you can see why I draw this wing section on the plans without dihedral. This drawing would be useless if it depicted the wing “properly”! From the reference images and descriptions it seems that the wing tip had the NACA-2409 airfoil. In the first approximation I scaled down the rib of the tip, fitting it to the reference drawing. (To fit this mesh to the front view I temporarily rotated the wing by its dihedral angle — 10⁰ 8’ — as in the picture below). However, although scaling down the original NACA-2415 coordinates produces the NACA-2409, it does not work precisely for the airfoil shape recreated with the Bezier curves. To fix these small differences I prepared an auxiliary “guide” rib of the NACA-2409 airfoil and placed it in the tip. (see the picture above). Then I modified the wing tip airfoil, fitting the wing surface to the contour of this guide rib (you can see on the picture that it minimally protrudes from the wing – as a very thin line).

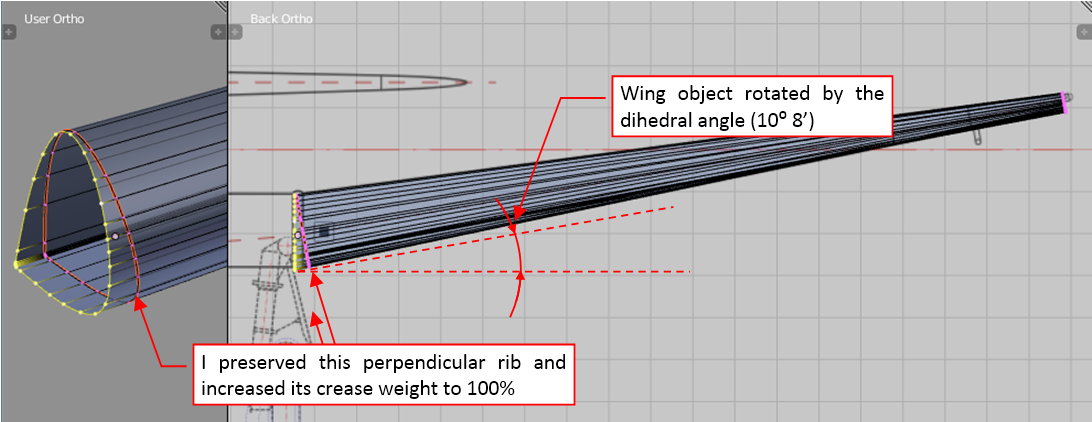

Then I rotated the root airfoil, adjusting it to the wing dihedral:

In the SBD Dauntless all the wing ribs were perpendicular to the wing chord plane, except the root rib of the outer panel. To easily insert properly oriented ribs in the middle of this wing, I inserted another rib after the skewed wing root rib. It is perpendicular to the chord plane. I marked this rib edge as “sharp” (by increasing its Crease weight to 100% —you can recognize it on the picture by different edge color). In this way I ensured that the skewed root rib has no influence on the new edges I will add in the middle of this mesh.

In the Catmull-Clark subdivision surfaces, you can use the Crease weights to obtain a local sharp edge or to separate a mesh fragment from the influence of the outer mesh vertices. I learned this method from a Pixar paper, presented on SIGGRAPH 2000 by Tony DeRose. (Before I started my first model, I studied the subdivision surfaces math, to know better properties of the basic “material” used in the digital modeling).

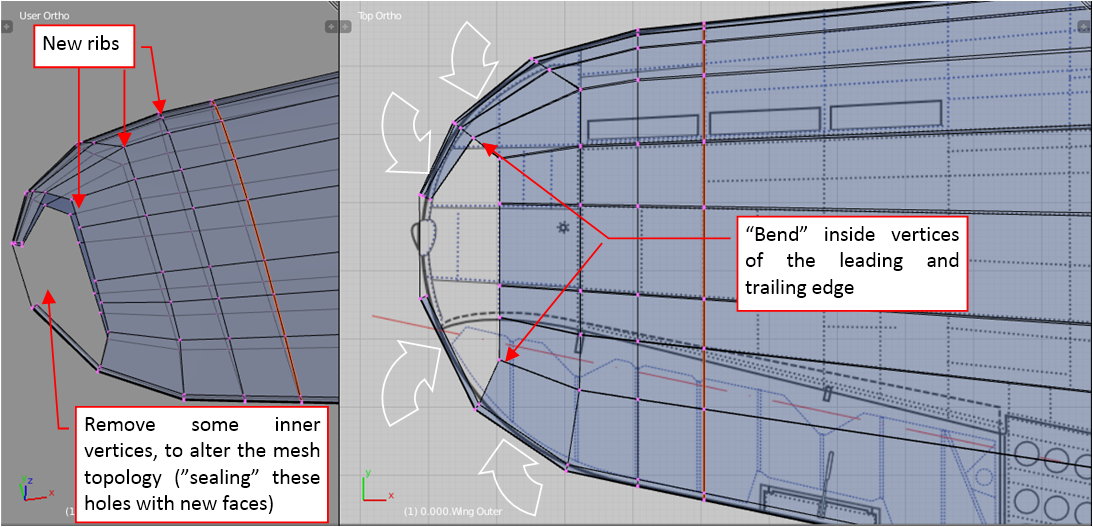

I had an occasion to learn that it works as expected in the next step: forming of the rounded wing tip. First I inserted into the tip area a few new ribs (using the Loop Cut command). Then I started bending their trailing and leading edges, to finally join them into an arch:

As you can see in this picture, I also removed some of the internal mesh faces. I did it because I had to alter the topology of this area. (It is easier for me to determine the new faces when the old ones are removed).

Note that it was a good idea to have the same number of vertices on the trailing and leading edge. Now I can easily join them at the wing tip.

Figure below shows the resulting surface:

Note that the wing tip edge lies on the wing chord plane. As we can see from the reference drawing, in the real airplane the wing tips were slightly bent upward. We can easily obtain such an effect by moving upward (and slightly rotating) last vertices of the tip:

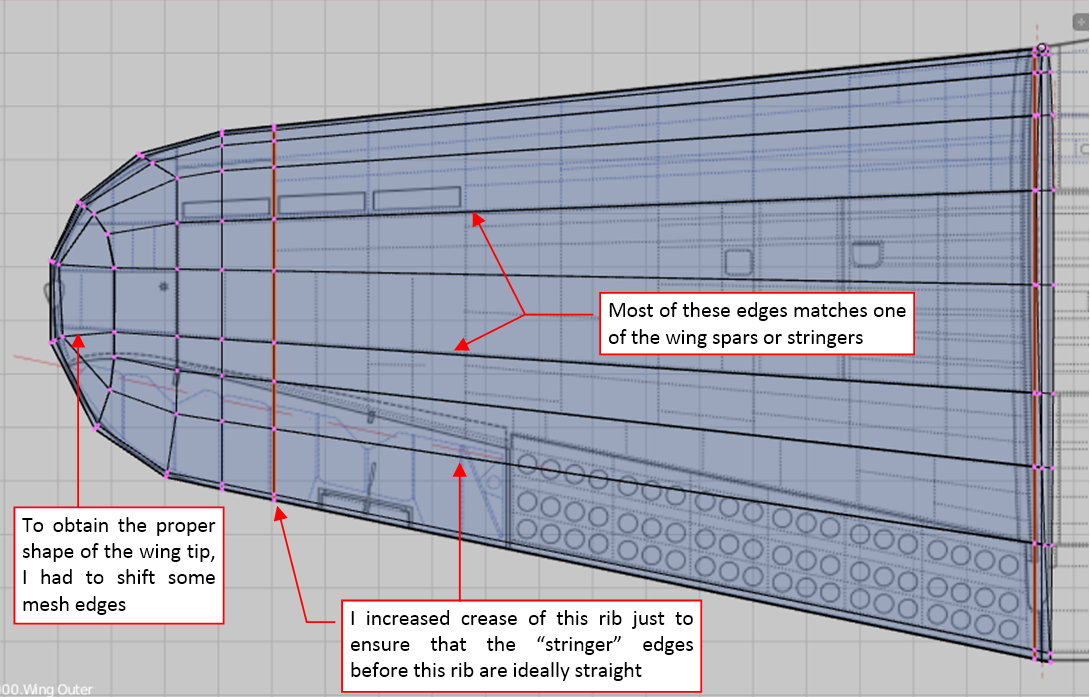

In the figure below you can see the control (i.e. not subdivided) mesh of this wing:

Note that I tried to align as many “longitudinal” mesh edges as possible to the stringers and spars visible on the reference drawing. This will be extremely useful when I draw skin details on the wing surface unwrapped in the UV space (for texturing).

In this source *.blend file you can check any detail of the mesh presented in this post. The next post will describe further steps of the wing modeling: separation of the aileron and forming of its bay in the wing.

This blog provides just an overall picture of the process. If you want to learn more about Blender, digital aircraft modeling and subdivision surfaces, see this guide: “Virtual Airplane” (vol. II).