In the previous post I promised that I will start the UV-unwrapping. However, last week I found a new edition of Bert Kinzey’s “SBD Dauntless” book. After ten years break, Bert started to continue his “Detail & Scale” series, this time in a different form: digital editions. This e-book is the “updated and revised” version of an earlier publication (from 1995). For me, the most important part of Kinzey’s books are the “walk around” photos. They differ from all other “walk arounds” by careful selection of the pictures and comprehensive comments that explain many technical details depicted on these images. Usually these comments are as important as the photos.

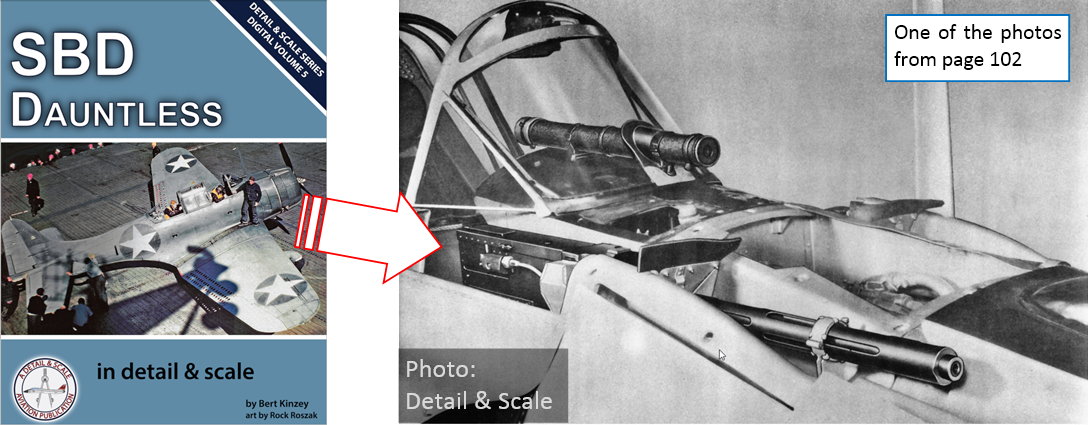

Take for example such a caption that you can find on page 102, below the picture of the forward firing guns (as in figure above):

All versions of the Dauntless had two fixed, forward-firing, .50-caliber machine guns which were fired by the pilot. This photograph was taken from the Pilot’s Manual for the SBD-2, and it shows both of the two fixed guns in place. However, the manual also states that the left side gun was usually removed from the SBD-2 in order to save weight. This was done only on the SBD-2 and usually only during peacetime. Once the war started, the additional firepower of the second gun was more important than the weight advantage gained from deleting one of these guns.

It is a great clarification that cites a reliable source: the original manual. In the other books on this subject you can find various, often contradictory versions about the SBD-1 and SBD-2 forward guns. For example:

Pilots’ armament [of the SBD-2] was increased from one to two .50 caliber guns (Barret Tillman, “The Dauntless Dive Bomber of World War Two”, Naval Institute Press, 2006, page 8);

This statement implies that the SBD-1 had a single 0.50 gun! (And it does not tell us about the source of this revelation).

Another one:

To retain the center of gravity (CoG) position [in the SBD-2], one of the forward-firing machine guns was removed (Robert Pęczkowski, “Douglas SBD Dauntless”, Mushroom Model Publications 2007, page 8);

This statement implies that all SBD-2 had a single 0.50 gun because of the design reasons (aircraft balance). This is also an information without specified source.

You can find in the Web many other descriptions of the SBD-1 and SBD-2. I remember that I encountered somewhere yet another variation of this story. It stated that the pilot in the SBD-1 had two smaller, 0.30-caliber guns.

I am really happy that Bert gives us the ultimate answer on this issue. (In another place in his book he mentions that for this writing he used the six original manuals, one for every Dauntless version. That’s why I take for granted his statement that all SBDs had two 0.50 forward guns).

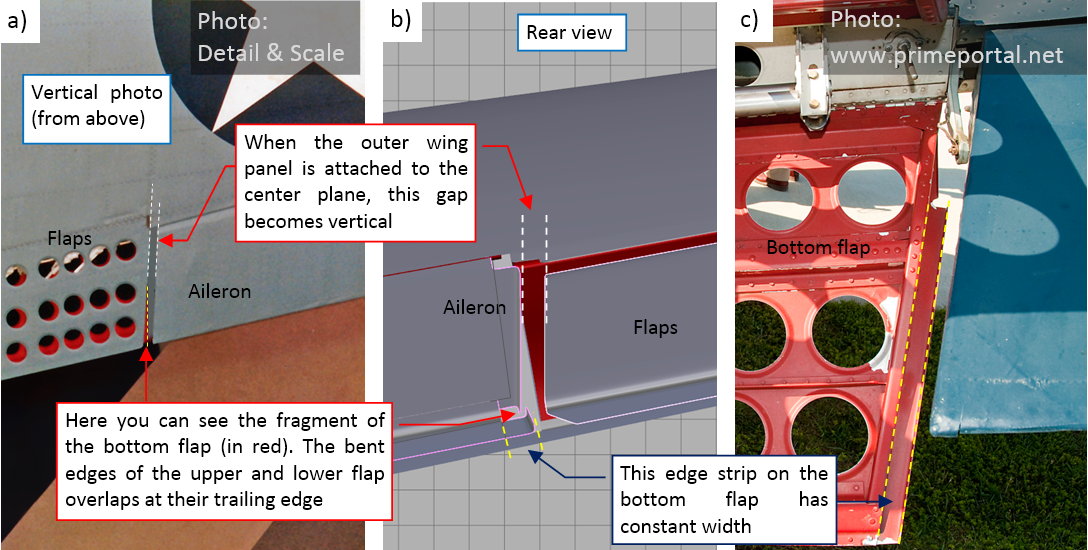

In the chapter about wings (page 85) I found the confirmation of my hypothesis about the overlapped flap edges:

Compare figure above with the second-last picture from my post from previous week. This was a result of the deduction, because when I wrote it, I had no such a vertical photo of the wing with closed flaps.

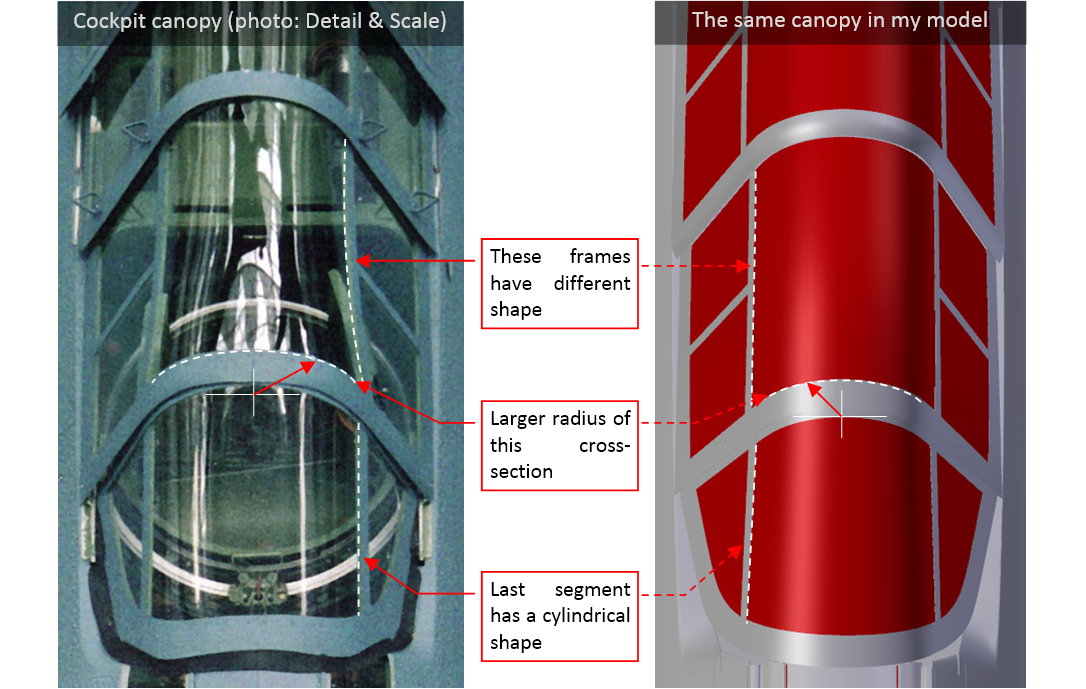

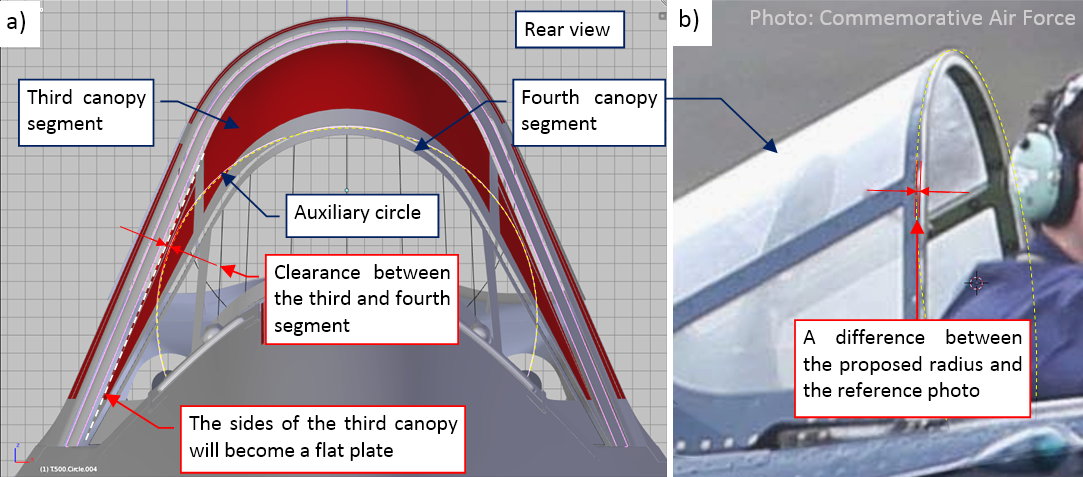

However, when I studied the photos of the cockpit canopy, I noticed a difference in the shape of the rear segments:

Figure "a", above, shows a fragment of the photo, taken from above. It reveals that the upper part of the last segment had a cylindrical surface, and the radius of the cross section between the third and the last canopy segment was larger than in my model (shown in figure "b", above).

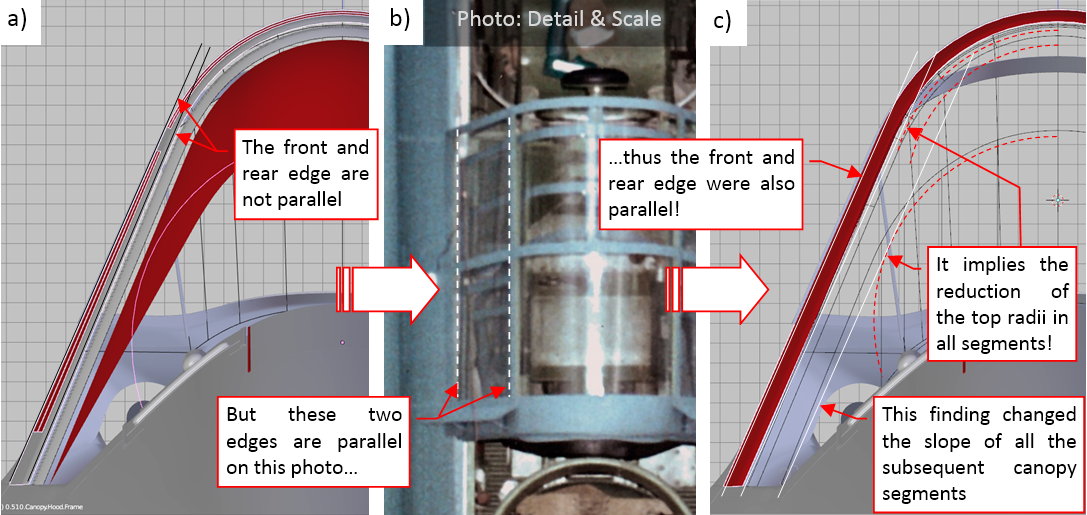

It was further confirmed by all other photos: the side edges of all cockpit canopy segments were parallel, while in my model they are not:

I had to be blind that I did not noticed this mistake before! In fact, it happens when you stick too much to your assumptions about particular shape. In such a state of mind you can see only the details that confirm your hypothesis, and neglecting the others. I assumed that the top radius of the subsequent canopy segments decreased like in the telescope tube: each segment has smaller radius than the previous one. In the effect I received much smaller radius at the end of the third canopy segment than you can see on the Detail & Scale photo.

As the first approximation of this radius I placed inside the model an auxiliary circle (Figure "a", below):

I fitted this circle between the sides of the previous segment and decreased it by an appropriate clearance. Then I checked how it looks in another reference photo (Figure "b", above). In this way I have found that it should be slightly smaller. Thus I started to search for the reason of such a result.

BTW: I used the same reference photo before, to verify the pervious cross section. I determined then that it had much smaller radius than the result presented above. This situation shows that you always have to double check every model element on multiple pictures!

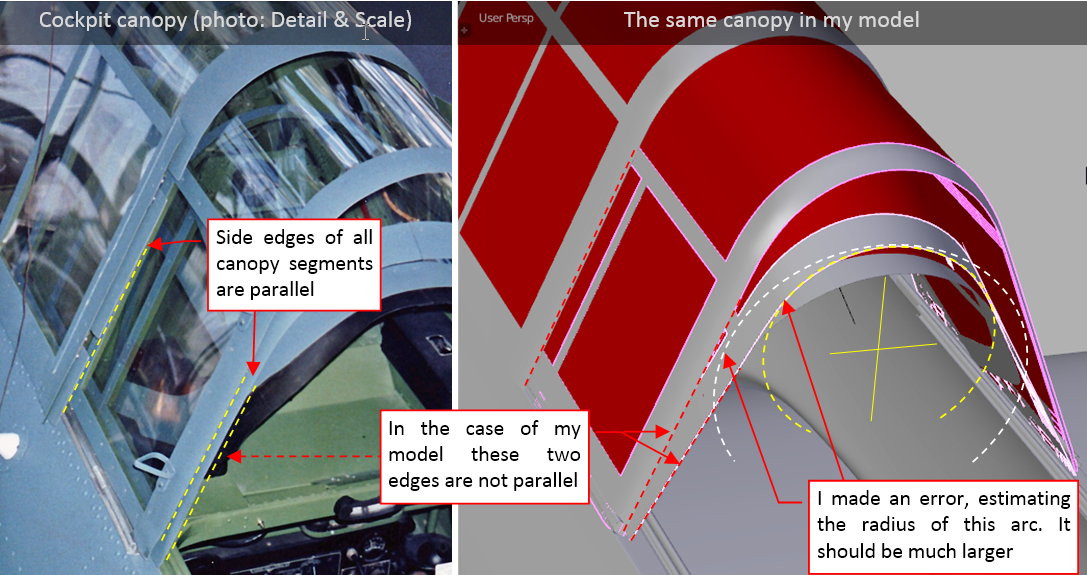

Finally I think that I found the reason: the canopy sides should have a little less steep slope in the rear view. The error comes from the wrong assumption about the shape of the pilot’s canopy:

I assumed that the upper horizontal “sticks” of this canopy frame were nearly parallel to the fuselage centerline. In the effect the front and the rear edges of this segment were not parallel (figure "a", above). The photo from Detail & Scale book reveals that I was wrong (Figure "b", above). You can see on this shot from above that both horizontal elements of this canopy frame are parallel to the cockpit border edge. Thus I had to rotate a little the rear edge of the pilot’s canopy, making it parallel to the front edge. It forced me to decrease (by scaling) the radius of the arc that closes the upper part of this canopy. In the effect, I will have to decrease the corresponding arcs in all subsequent canopy segments, including the last segment. As I mentioned in one of the previous posts, I tried to avoid such things, but nevertheless I am prepared: the meshes of my model are relatively simple, so such a modification is not a great problem.

If you want to create a precise copy of any complex object, be prepared that from time to time you have to step back and alter the shape of some finished elements. The work on such a model more resembles a “spiral” than the classic “waterfall” process.

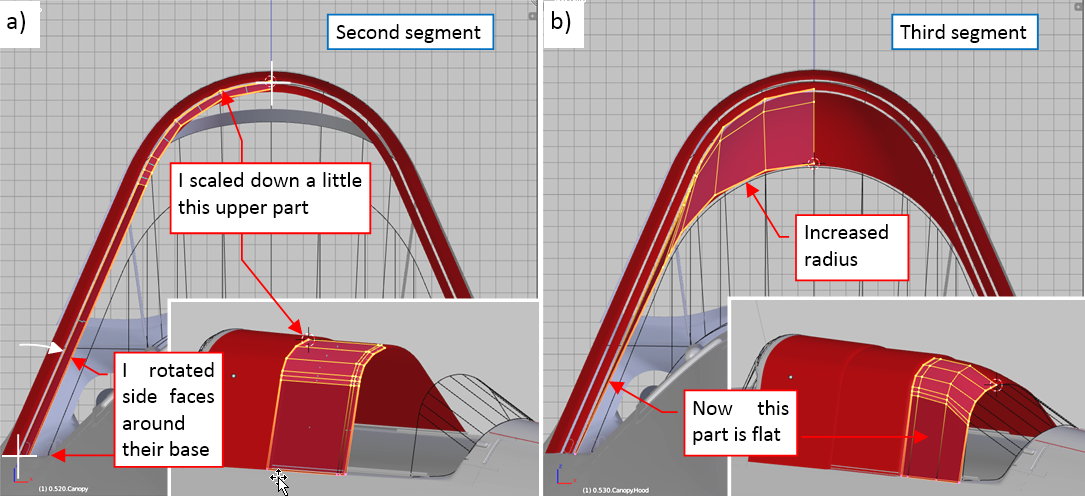

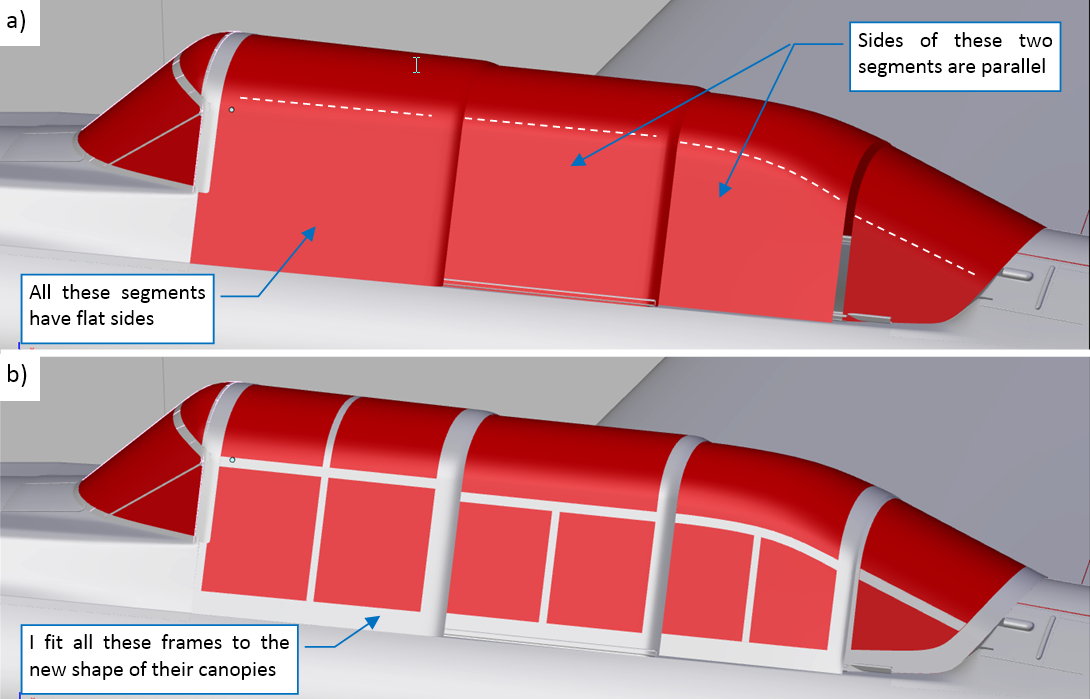

Well, I documented these small bur laborious modifications on the pictures below. Generally, in each canopy segment I had to rotate the side faces along their base (see it in the second segment, depicted in Figure "a", below). Then I scaled down (a little) the upper faces of such a mesh, decreasing in this way the cross-section radius of the resulting surface.

The third segment was more difficult, because the radius of the top arc in its cross sections increases toward the rear (Figure "b", above).

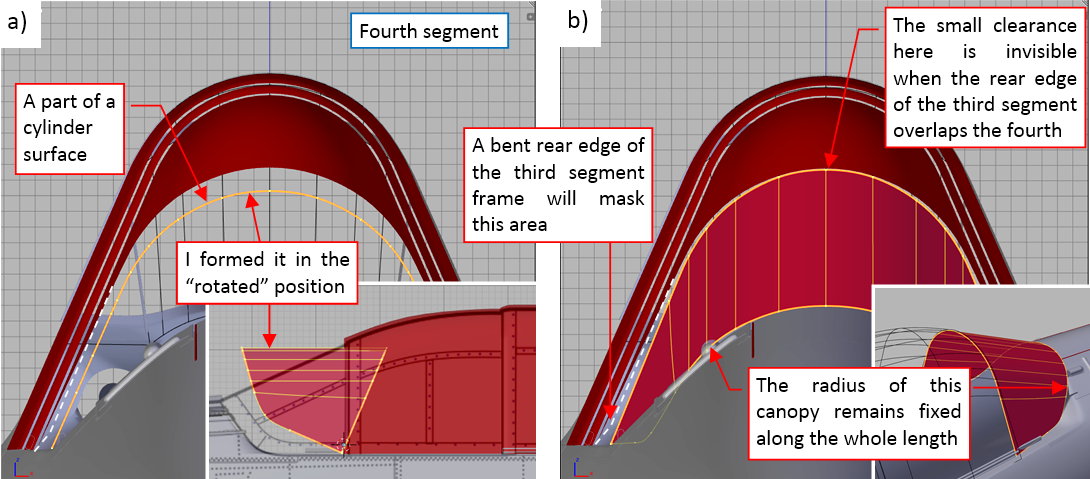

The most difficult part was the last, fourth canopy segment (see the picture below). First I formed its faces in the rotated position (figure "a", below), ensuring that it properly slides into the previous segment, and that its upper part forms a clean cylindrical surface:

Then I rotated it back into “closed” position, and verified all other details (figure "b", above). Fortunately, it seems that the radius of its rear edge did not significantly change, and it still fits the rear border of the cockpit. (It still looks like in the reference photos). The biggest change occurred in the frontal cross section of this canopy segment.

Indeed, I already altered this radius before: see this post, Figure 57-5. You can see that I made a wrong decision that time, decreasing this section instead of increasing the rear edge of the previous canopy segment. This is a typical “fitting” error, which occurs quite often!

Figure "a", below, shows the modified shape of the cockpit canopy:

Figure "b", above, shows the same canopy with the updated frames. It is hard to notice any of my changes in this side view, isn’t it? In fact, fitting anew the frame meshes to the altered canopy segments required even more time than the adjusting of the canopy basic shapes! I am really happy that some posts ago I managed to tame the temptation to recreate the internal frames of these canopies. Now I would have much more work with them.

That’s why I am going to recreate all the internal details in the last, fourth phase of this project. In this way I am just creating “time buffer” for eventual new findings, like this one.

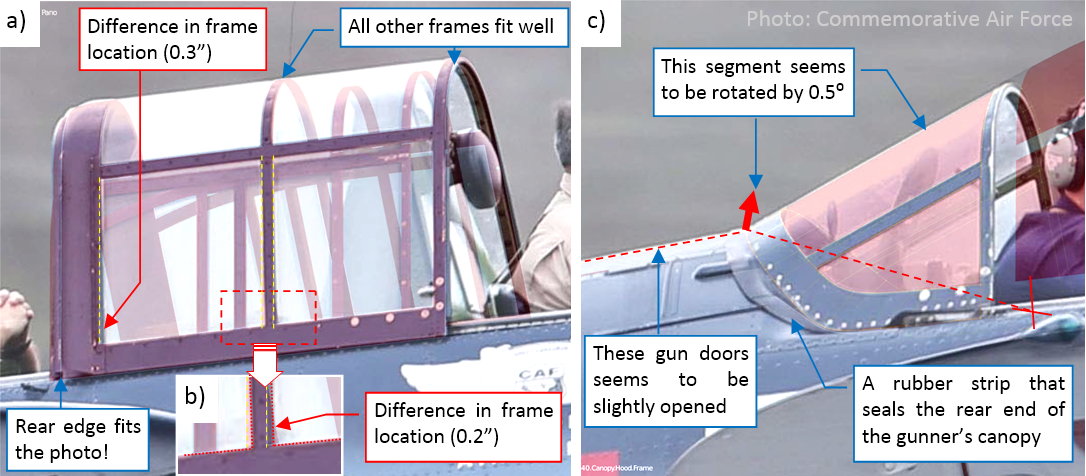

Of course I checked the updated canopy on the reference photos. This time I did not want to be blind on eventual differences — as you saw in this post, even slight distance between the model and the photo can indicate a significant error. I slid all the canopy segments into “open” position, to compare them to the CAF photo (this photo has the highest available resolution - see figure "a", below):

To better see the model on this picture, I assigned a red material to these frame objects. As you can see, most of the canopy frames match the photo. However, there are two exceptions, on the pilot’s cockpit canopy. The bottom ends of the middle and rear frames seem to be shifted (by about 0.2” and 0.3”). It could mean that the slope of these canopy sides had a slightly different angle. However, the front edge and the rear edge of this segment match the photo (figure "a", above). At this moment I will leave this difference unresolved — maybe in the future I will find something, which will help me to explain this difference.

There are also slight differences in the last canopy segment (figure "b", above). However, I think that I can explain them now. This part of the cockpit canopy has two degrees of freedom: you can slide it as well as rotate around its corner. The canopy in figure "b" seems to be rotated by about 0.5⁰. Such a small rotation can be within the tolerance of its lock mechanism. It can be caused by the gun doors, which seem to be slightly opened in this photo. There is also a thick rubber (or leather) strip around the rear edge of this canopy segment. It seals the rear border of the cockpit. (I will recreate it later). I think that the influence of the gun doors and this strip can rotate of this last canopy segment by such a small angle.

In this source *.blend file you can evaluate yourself the current version of the model, described in this post.

This post ends the “modeling” stage of this project. During this phase I formed the general shape of the model, and created all the surfaces which require the classic “image” textures. In the next post I will unwrap these surfaces in the UV space, preparing them for the “painting”. For all other details that I will create during the last, “detailing” phase, I will use procedural textures, which do not require UV-mapping. (The only exception are certain elements of the cockpit interiors, like the instrument panels, but they will have their own, separate texture images).