Pat, thank you for following!

Below another post, this time about specific detail: recreating the aircraft skin abrasions. To provide a complete picture to eventual other 3D modelers, I described here the "kitchen details" of the Blender node setups. (I know that it may look like a "rocket science" for those who never used it :). However, this is one of the last posts about "painting". I will finish this phase soon, then will provide posts on modeling more classic elements when I start to work on the details: undercarriage, engine, etc.)

_________________________________________________________

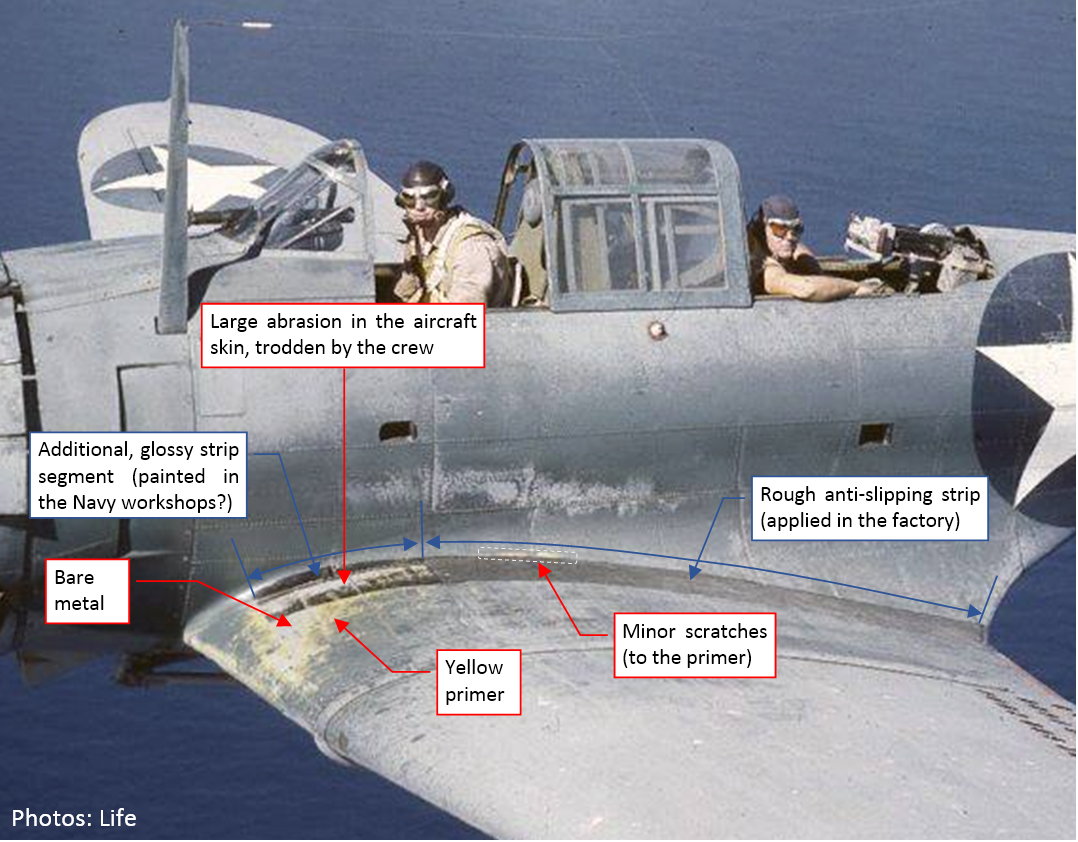

It seems that Douglas used a high-quality paint for their SBDs, because I cannot find any trace of chips/flakes, even on such a worn-out aircraft as this from VSMB-241 (see figure below). However, you can see some scratches on the center wing, trodden by the crew:

In the photo above, the minor scratches are yellow, because Douglas used a yellow layer of Zinc Chromate primer below the camouflage paint. (The interiors were painted with another layer of the Zinc Chromate, mixed with Lamp Black to obtain a darker, greenish hue).

However, the larger area along the leading edge was often trodden to the bare metal, which you can see in the photo. This scratch has a typical, irregular band of the primer around its borders. In this post I will recreate these abrasions.

The aircraft producer anticipated this kind of damage (at least to some extent), placing a thick, rough, anti-slip strip along the fuselage. It seems to be made of a black, rough material, glued (?) to the aircraft skin (as in the picture above), and spans from the trailing edge to the main spar. However, the most “visited” by the servicemen area in the front of this spar had no such a cover. On some SBDs (including the one on the photo above) you can find a glossy, black continuation of the anti-slip strip. I suppose that it was added in the Navy workshops. It seems to be simply painted using a typical black paint, thus was more prone to the abrasion (as you can see in the photo).

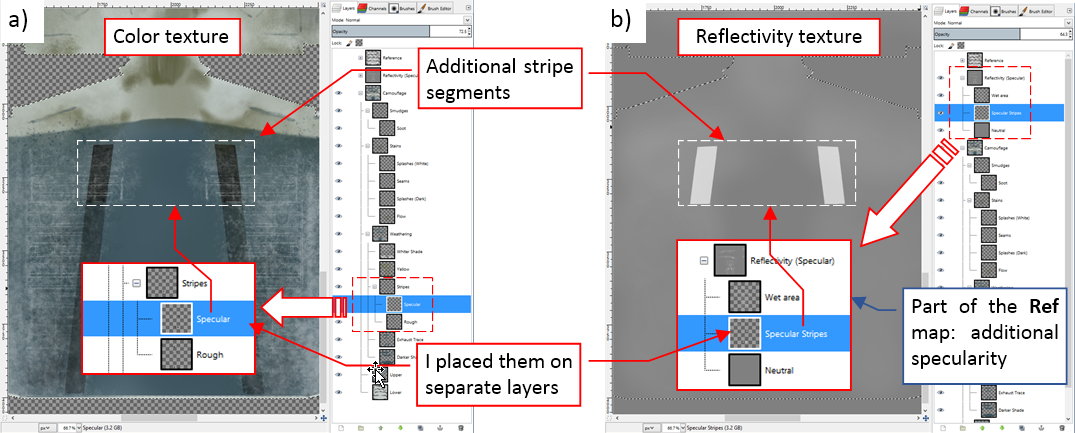

To recreate the effects from this archival photo, I had to paint this glossy black area first. It requires changes in the two textures: color map (because it was black) and reflectivity map (because it was glossy). I created in the source GIMP file separate layers to reproduce these shapes. This way I can simply turn them off while painting another aircraft that did not have this feature (like most of the SBD-5s and -6s). Figure "a", below, shows the color texture image, while figure "b" shows the additional reflectivity map (they share the same GIMP file):

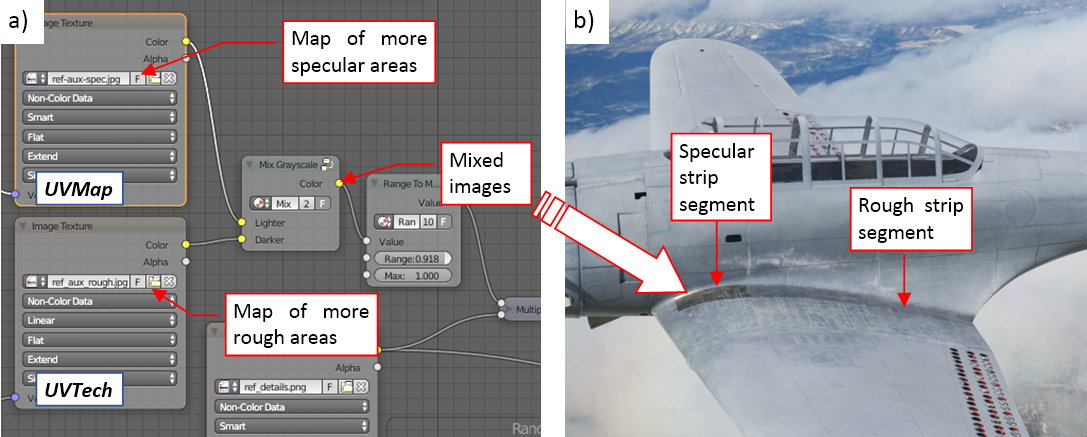

Note that I introduced here another part of the reflectivity texture: the map of the areas that are more specular than other. This is a natural addition to the ref-aux.png map that I used in this post to make the remaining anti-slip strip more rough. There are also some other areas that look more “wet” (specular) than the others. For example – the fuselage sides (because of the small amounts of the oil, spreaded from the engine). I painted them in GIMP in a lighter gray, on a separate layer named Wet area (see Figure "b", above). I saved this image to a file named ref-aux-spec.jpg. However, I could not simple merge it with the ref-aux.png map, because it uses the different UV layout (UVTech). Thus I had to join these images in Blender, using special node that mixes two grayscale pictures (as in Figure "a", below):

For the brevity I renamed the ref-aux.png file to ref-aux-rough.png. Figure "b", above, shows these updated textures on the rendered picture. Frankly speaking, the weak increase in the specularity of the fuselage sides is not visible here, but you can see the much more accented difference between the reflectivity of the forward and the rear anti-slip strip segments.

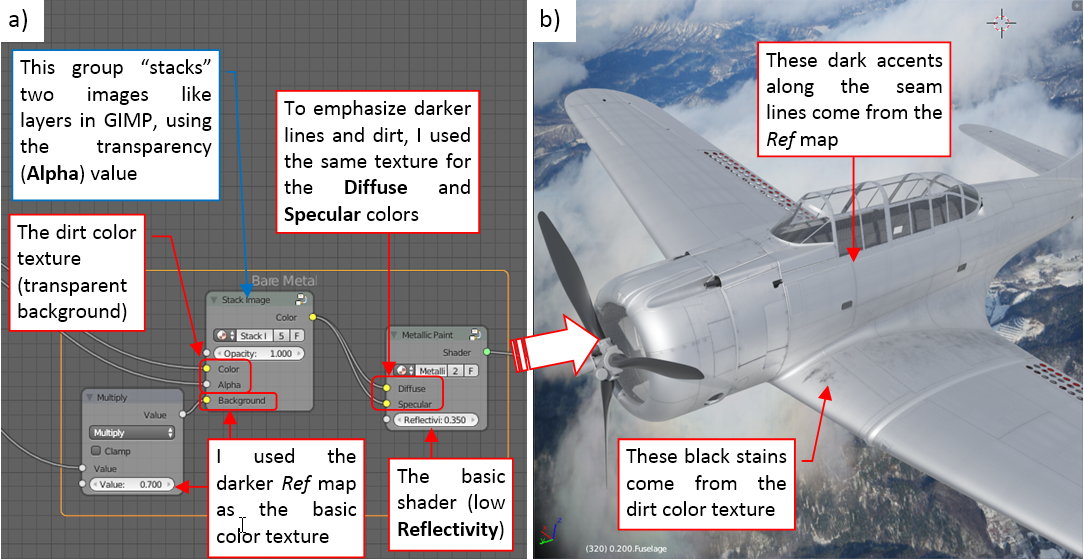

I am going to recreate the scratches that you can see in the archival photo using so-called shader mask. Thus, in addition to the weathered camouflage shader that I used so far, I need a “bare metal” shader, which looks like a rough duralumin skin. Figure below shows such a thing:

Note that this shader uses the ref_details.png image (see Figure 73-4 in this post) as the base color texture (for the Diffuse as well as the Specular colors). The dark lines from this image create appropriate shadows along the seam lines. I just made this input image somewhat darker (using a Multiple node), to transform the semi-white background color of the original ref_details.png image into metallic gray. What’s surprising, it’s better to use a fixed Reflectivity for such rough (low-reflectivity) metallic shaders. When I tried to use the same ref_details.png image as the reflectivity map for this case, it made the panel seams lighter, reverting the effects of the color texture.

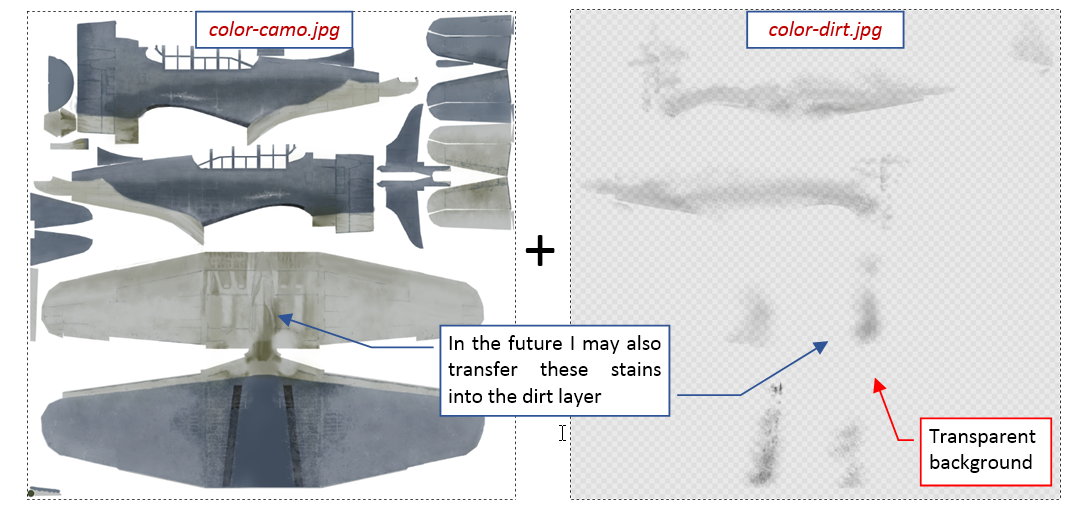

To share the dirt between the “bare metal” and the camouflage shaders, I separated it from the color texture. I named the two resulting images as color-camo.jpg (the weathered camouflage) and color-dirt.png (the soot traces and some stains on transparent background). I used the Stack Image nodes (see Figure "a", above) to combine them with corresponding backgrounds, like the layers in GIMP. Figure below shows these two components of the color texture image:

In the color-dirt.png image I initially grouped only the soot traces. It is possible that I will also transfer other layers there. (We will see if I have to do this during the work on the pre-war “natural finish” painting scheme of the SBD-1).

Then I prepared a B/W “shader mask”, painting white, feathered scratches on a black background:

As you can see in Figure "a", above, I decreased the opacity of these shader mask layers while painting, using as the reference the camouflage from the layers below. I also used a copy of the reference image (layer Rivets and seams) to precisely recreate technical details visible inside this scratch. (SBD had flush rivets on this area. Usually the paint remains on their heads even when there is bare metal around). Figure "b", above, shows the final material mask. I saved it to a file named mask-scratches.jpg.

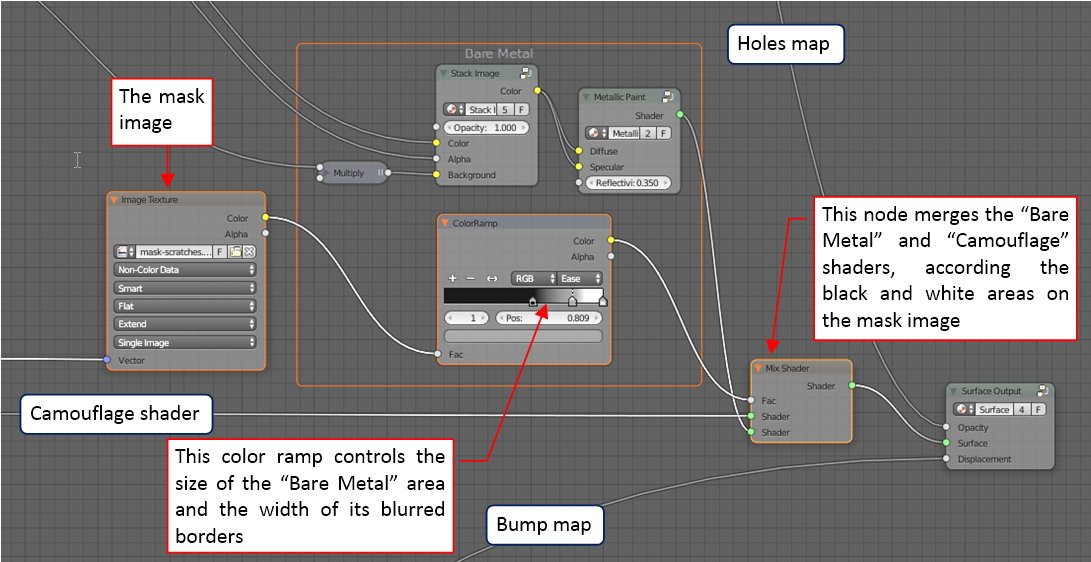

Below you can see how I used this mask in the material scheme:

Note that I placed a Color Ramp strip between the mask and the Mix Shader node. The pattern, set in this node, controls the ultimate size of the scratches, and the width of the transition area. (The transition area is “feathered” border of these bare metal scratches, where the share of both shaders is greater than 0). For example, if I want to get the “chips” effect (bare metal areas with sharp borders) I should switch this color ramp mode from Ease to Constant. (It creates a strip that contains just sharp black and white spans, without any “gray transition” between them).

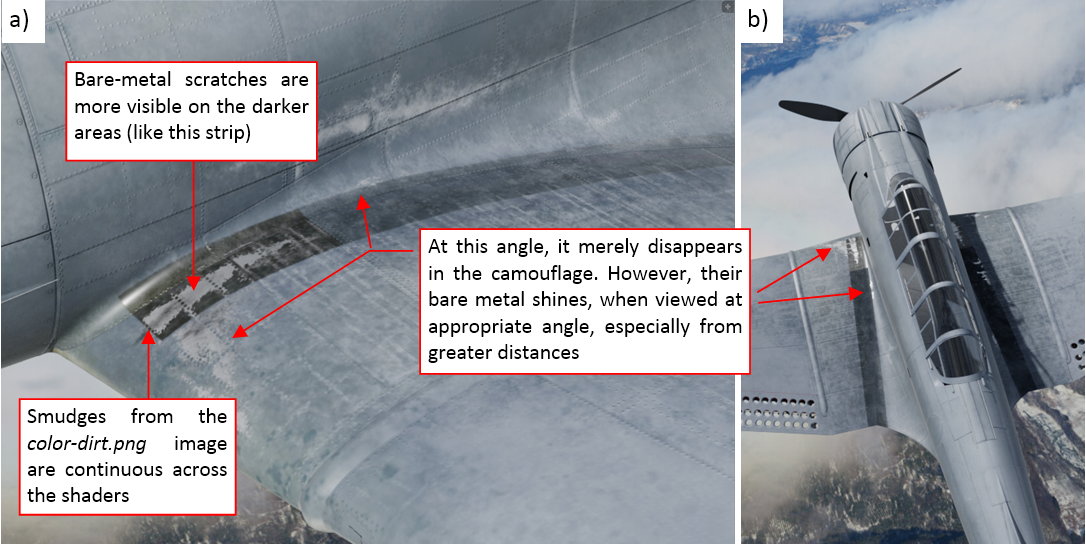

The result of this shader mask looks like the test render below:

The bare metal scratches look good on the dark background (like the anti-slip strip). For certain viewing angles they disappear in the camouflage, because of their gray color (as in Figure "a", above). Still, they can shine (as in Figure "B", above) when you view them from other sides, especially when you do it from greater distances. (This shining effect looks quite convincing – this is the advantage of this method over scratches painted directly on the color texture).

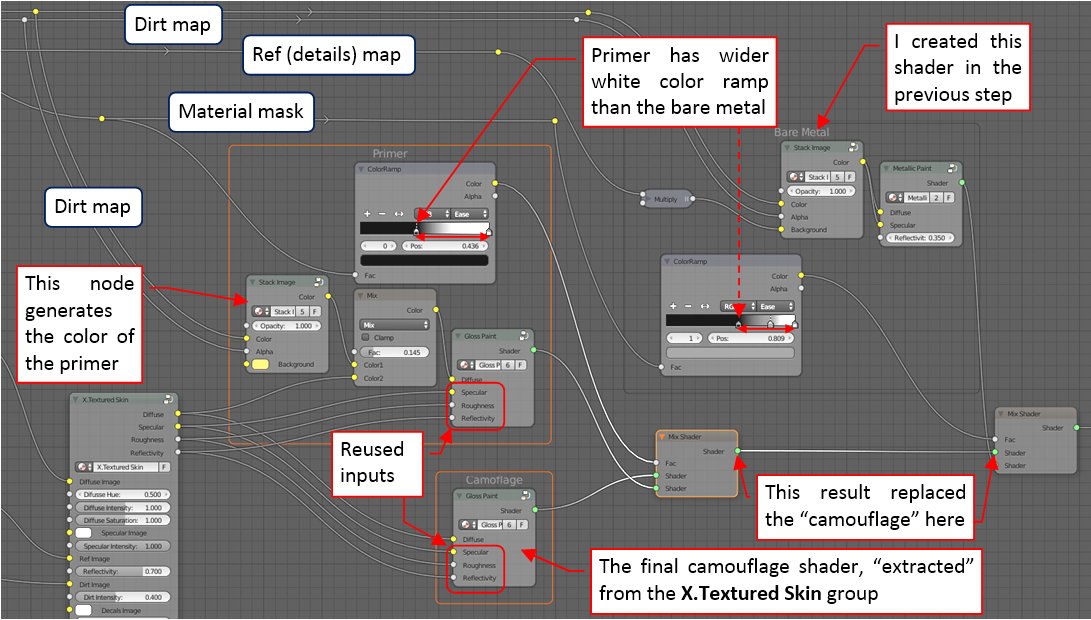

Now, let’s add the primer to these abrasions! This means that we have to add yet another shader to our material scheme. It is similar to the camouflage shader, with one exception: it has to have a uniform yellow color, instead of the camouflage texture. To reuse all the other settings, I decided to “extract” the final Gloss Paint shader from the X.Textured Skin group. Figure below shows the modified material scheme:

I “cascaded” the camouflage, primer and bare metal shaders, using two Mix Shader nodes. In general, each Mix Shader could use a different mask image. In this case both use the same input mask, but each one modifies it in a different way, using its Color Ramp node.

You can see the result below:

I think that it looks good enough. These and other details bring the final effect closer to the original photo from the beginning of this post (compare the picture below with the first picture in this post):

Of course, there are still differences. (For example - I have impression, that I should use stronger sunlight in my scene, to obtain such a high contrast between the lighter and darker areas as in the original photo). Well, I will work on these issues later.

Using the shader setup presenting in this post, painting all other scratches is a breeze: you just have to add another white splash on the shader mask image.

In the next post I will prepare the “decals” texture, containing national insignia, tactical numbers, and some service labels. (I will add more of these labels during the detailing phase, when I review each area of the aircraft skin).

In this source *.blend file you can evaluate yourself the current version of the model, and here is the GIMP source file of its textures. Because of the large size of the original GIMP file (*.xcf), this post is accompanied by its smaller version (2048x2048px), packed into *.zip file. I think that such a version is sufficient for checking all the details of this image (the structure of its layers, their opacities and mixing functions). The resulting textures (4096x4096) are packed into accompanying Blender file.