Inserted 7/3/19 from my notes.

Adding the Longitudinal Stiffeners to the Fuselage

The longitudinal stiffeners were thick metal strips added to both sides of the fuselage to strengthen the frame and reduce the side-to-side motion of the tail during flight. These stiffeners are not rendered in the kit but they are a noticeable feature of the real B-52D.

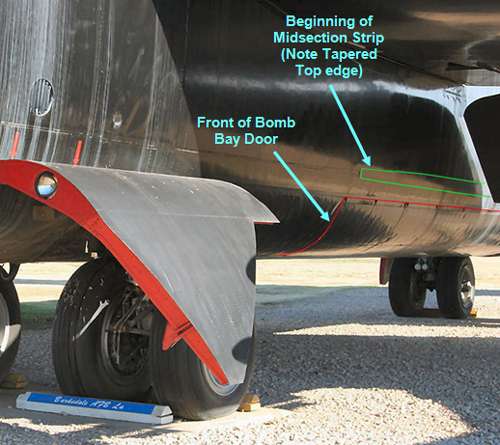

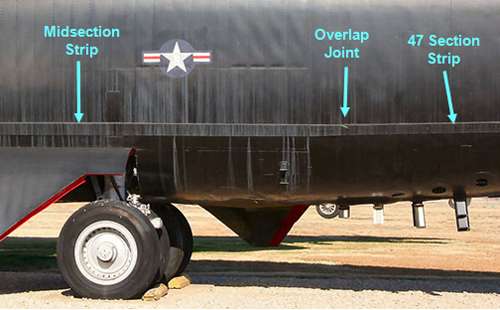

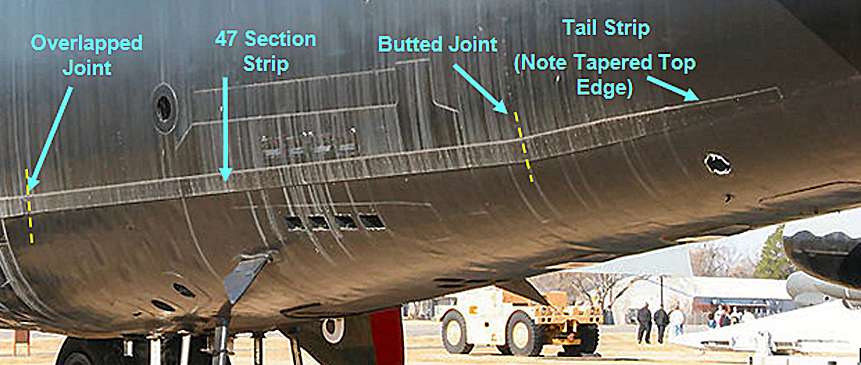

Each stiffener begins at the front edge of the bomb bay and goes all the way back to just under the leading edge of the horizontal stabilizer, as shown in the three photos below. It looks like a single piece but was actually made up of three strips which I've named: Midsection strip, 47-Section strip and Tail strip.

The stiffiners are made from 1 mm sheet styrene or equivalent stock. Cut 6 strips as follows:

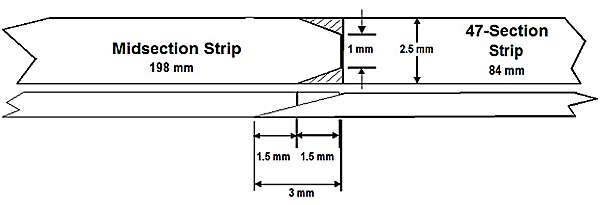

2 strips 2.5 mm wide x 198 mm long (Midsection Strips)

2 strips 2.5 mm wide x 84 mm long (47-Section Strips)

2 strips 2.5 mm wide x 33 mm long (Tail Strips)

Add the Left Side Tail Strip First

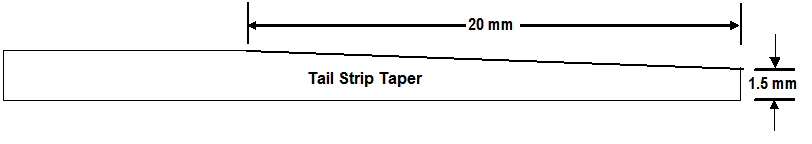

1.) Lay a Tail strip on a cutting surface, then taper the right end according to the diagram below.

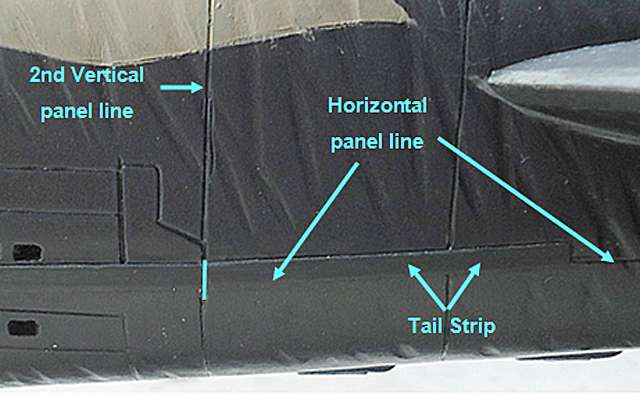

2.) Starting with the left fuselage half, locate the second vertical panel line in front of the horizontal stabilizer, as shown below. Follow this panel line down to the horizontal panel line that runs along the bottom half of the fuselage. This junction will mark the location of the left end of the Tail strip.

3.) Place the strip so that the bottom edge is aligned with the horizontal panel line and the bottom left corner is flush with the vertical panel line. The top edge will be slightly past the vertical panel line due to the change in direction of the horizontal panel line at this point.

4.) Trim the left end of the strip so it is parallel with the vertical panel line, as shown below.

5.) Glue the Tail strip to the fuselage.

Next, Add the 47-Section Strip

1.) Lay a 47-Section strip along the horizontal panel line and trim the right end as necessary to butt up against the Tail strip.

2.) Since the Midsection strip will overlap the left end of the 47-Section strip (overlap joint), you will need to taper the left end about 3mm, as shown in right half of the drawing below.

3.) Glue the 47-Section strip in place along the horizontal panel line.

Now Add the Midsection Strip

1.) Trim one end of the strip as shown in the left half of the drawing above. This will be the end that overlaps the 47-Section strip. Sand the overlapped ends so there is no buldge in the joint.

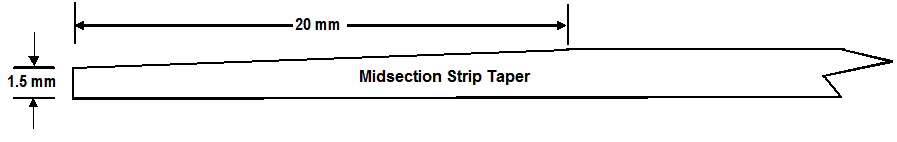

2.) Now taper the left end of the Midsection strip as shown in the drawing below.

3.) Align the bottom of the strip with the horizontal panel line and the right end with the 47-Section strip.

4.) Trim the left end as necessary to align it with the panel line at the front edge of the bomb bay door.

5.) Glue the strip in place.