Work has been progressing nicely on the Warrior. In addition to all the AM, i am also doing some scratch building, partly down to an issue with the AA conversion set that doesn't convert the from right of the hull, and also some other minor changes to the kit. And i decided to deal with one of these later changes first, the handles and covers for the fire engine compartment suppression system. There is one located on each side of the hull.

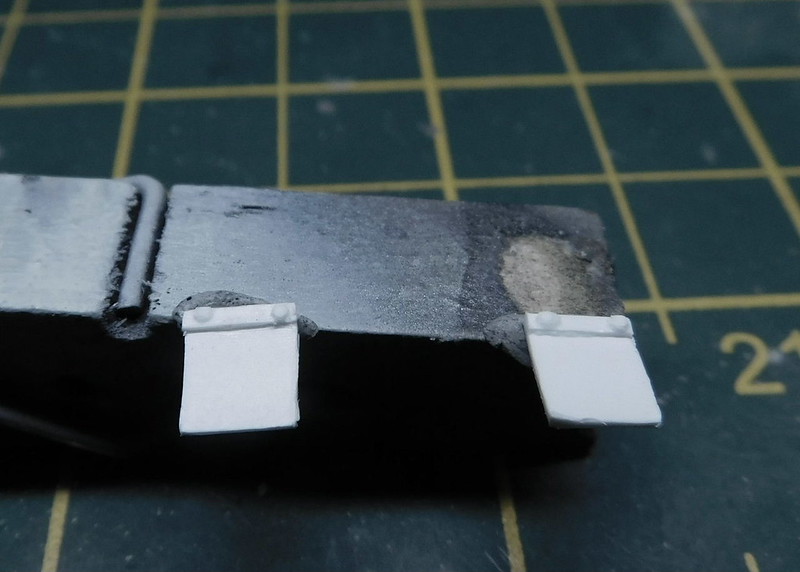

As you can see they are molded on and so very flat and un-natural looking. The real flaps are often curled up through regular lifting as part of the monthly inspections and other check. So the first thing i did is make some new ones with styrene sheet and strip useing the molded parts as a guide.

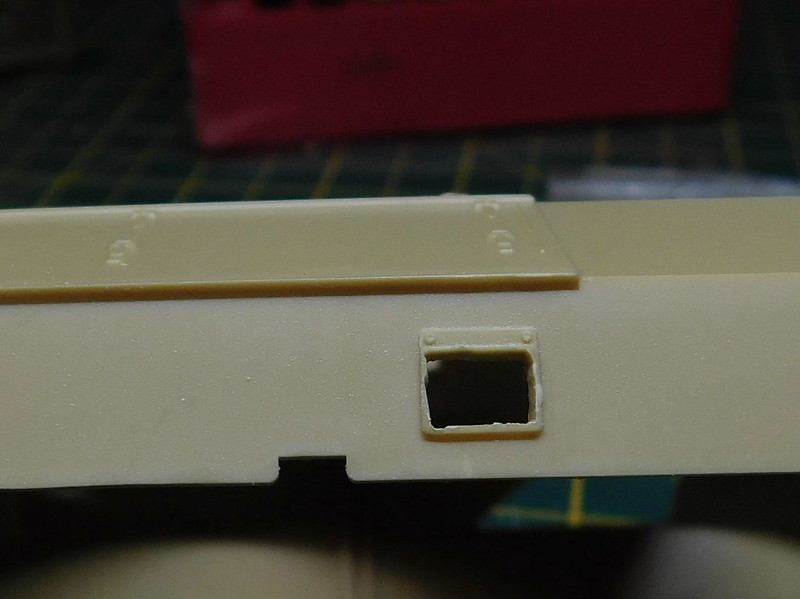

I then cut out the centre of the molded part leaving the securing strip and a bit around the edge.

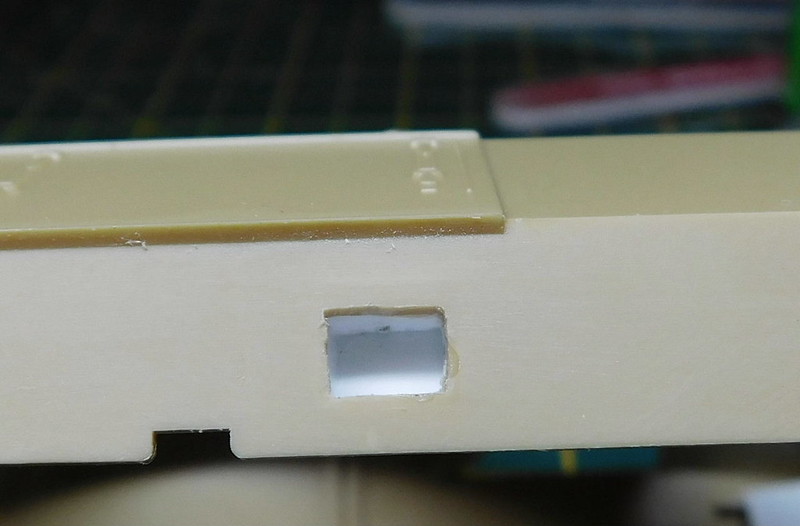

This was then sanded flat and the hole boxed in.

I then took a large piece of styrene rod, drilled it out, fitted into the hole. The space around was filled and then sanded flush. Now i just need to add the handle which i will probably have to scratch build.

I then decided to fit the running gear, a nice easy job, just attach the axle arms. But straight away i realised something didn't look right, and i realised that the opposing wheel stations didn't line up correctly. After a few moments and checking with a ruler, i noticed that the securing points for the torsion bars don't line up with there respective axle arm postions on the other side. This means that the torsion bars would run an angles across the hull and would have to cross over each other. makeing them un-workable.

Then i realised where the issue was. The wheel stations on the right side are the wrong way round. Both sides have the torsion bar securing points to the front of each wheel station, but on the right, they should be at the rear. This image shows the right side and i have indicated one of the securing points.

This photo from Prime Portal is also of the right side, this time a real warrior of course, and again, i have marked the torsion bar securing point.

I am really annoyed about this. I wanted this bild to be as accurate as possable, more so than with any other build. And this is such a silly mistake. Its clear the makers of this kit have no idea how a torsion bar suspensipon works.

I spent a while considering my options. I thought about slicing off each wheel station and turning them around. But they are so thin i would be sure to destroy at least one, and its not a simple case of just turning some of them. But, i do have one thing in my favour. After 2 weeks on salisbury plain, this area is covered in mud and dust that sets like concrete. So, i'll just have to cover it up. But i am still bloody annoyed.

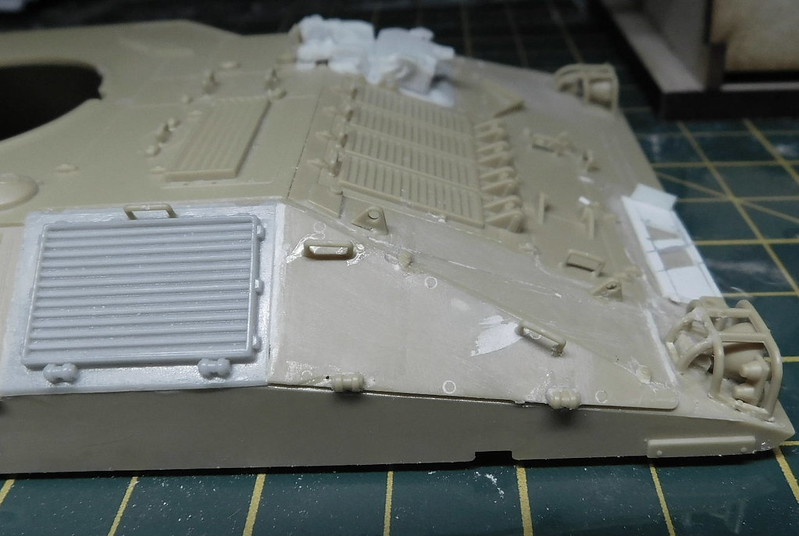

I also got the final drive housing fitted to the front. These are AA resin parts with weld seams around them and nice texture. You have top fill in the large hole for the kit part.

Next up i wanted to tackle the part of the conversion that the AA set leaves out, the front right corner. I think this is understandable given the shortage of close up photo's of that area of the Command and Artillery variants.

This pic shows the front of the upper hul The bit in blue and the bases for the lifting eyes which have to be removed, AA does tell you to do that. The large hole in the middle is where the main engine deck goes, and this is spot on for a 510. This would be removed along with the panels on top when lifting out the power pack. But on a 511, this piece of decking extends right to the edge, as indicated by the red line. Also, the molded piece to the bottom, which is the tool rack for the picks and sledge hammer need to be moved slight to the left side, right in the pic.

This is the main engine deck with the radiator covers. The parts indicated and the securing clamps and will have to be sliced off and moved to the new outer edge of the panel.

And this is the side panel. The liurve, whcih i had started to remove before i thought about getting a pic, need to come off. Thats fitted to the 510, 514 and 515 but not the 511. I also need to fit hinges to the bottom as this has to be opened to lift the main deck and reposion the handles.

And finally the light guards. On a 510, these are the same left and right. But on a 511, but the left one is the same as the 510, the right one does not extend so far back, otherwise it would extend onto the main engine deck.

And this is the result of the work need to correct this. The engine deck was fitted after the 2 clamps had been removed, and the seamed was filled in. The front of the engine deck has a slightly raised edge, so i carried this on with some styrene strip. The rear arms of the light guard were cut off, shortened and re-attached. I made a new tool rack useing the kit one as a guide, and after sanding the kit part smooth, i fited the new piece, 3mm further from the light that the kit part.

The side panel was smoothed out, the kit handles placed in the new positions. I thought i might have to scratch build the hinges, but after fitting the resin exhaust louvre, i realised the kit part had the same hinges, so this were sliced off and used here.

And you can see here that other parts have been fitted, all the handles, the new drivers hatch, lights etc. The lights are a vert tight fit as the edges of the light guards were to thick and i cut them down, but it meant the fit of the lights was slightly out. Also, the lights have solid lenses. But i will be covering these with sandbags anyway, so thats not a problem. You can just see a small object just between the light guard and the new tool rack. I don't kow anyone who ever figured out what that is for, but its on the vehciles. I thouhgt i mght have to scratch that, but after fitting the new drivers hatch, i noticed that the hinges for the kit hatch were exactly the same, and so i used one of those.

Also made a start on the rear deck, removing the periscope bases and fitted the top hatch. The domed piece on the edge of the hull with the 4 bolt heads on top is part of the NBC filter system. AA says not to fit this, but thats not correct.

And finally the right side with the resin exhaust part. The molded on straps to the rear will have to be removed and i will make a cover for the side stowage bin.

There a a few photo's on line of 511's, but most are not close up or very clear. One of the best is on Wikipedia, the main photo is labeled as a 510, but its nit, its a 511. As my memory is having to stretch back 13 years, all these pics have been useful in confirming certain items and the location of some thing. But i am guessing many of these did not come out until after AA did there conversion set. So they just used what info they had at the time.

More soon.