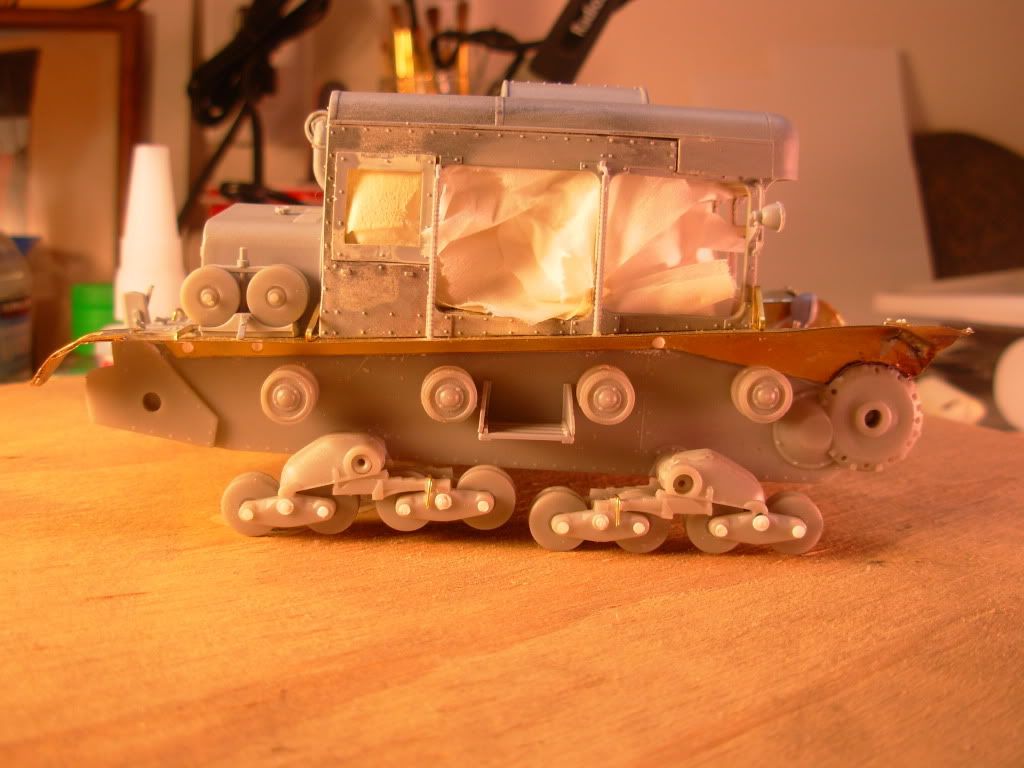

Well, the construction phase of this little guy is coming to an end. As much fun and growing as I did, despite it being a pretty crappy kit, it was my first attempt at scratchbuilding using brass for fenders, my first soldering, pin punch, all that jazz. Without Indy/Adam pushing me like Bull Meecham in he Great Santini, this thing would be on the shelf already with chunky style manwich fenders made of plastic.

Despite the time spent and the challenges, I am really glad I chose this one to do, and glad I took so much time to try to get it right, or at least better than it originally was. I'm a bit sad that now I need to cover it all up, I love painting and weathering, but I hate to cover up all this brass and styrene rivets.

Anyhow, here's my last review before priming, I don't mind putting off priming a while (although it might kill Ed) if I can fix anything anyone is nice enough to point out.

On to the walk around, sorry dial up guys, you are going to hate this:

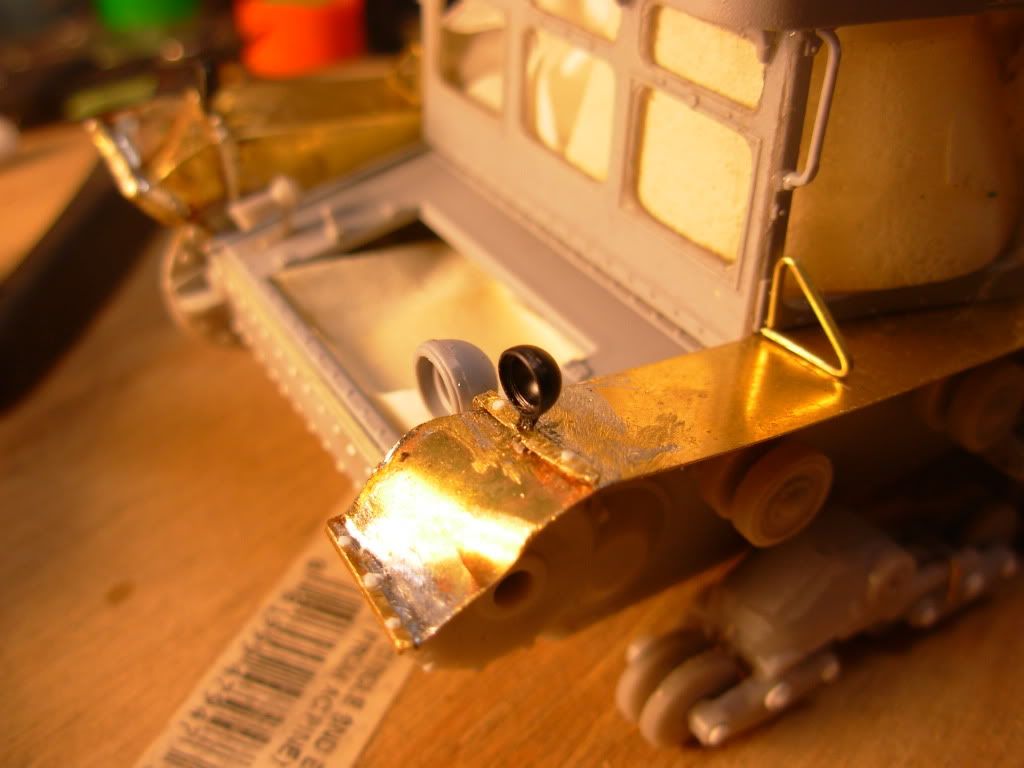

Finally, I almost forgot the fender mounted headlights, which turned out to be solid styrene "bullets," so I busted out the ELF replacement headlights, sized small on the large set, courtesy of Ed's recommendation, and voila, nicer lights.

Next time anyone sees her, she will be monotone primer grey, then I'll keep it under wraps until I get the paint done.

THanks for looking, please sound off if you see any problems that need to be dealt with before paint.

Bill