Hi all,

Thunderbolt379 reporting back for duty on the burning sands of the Sinai!

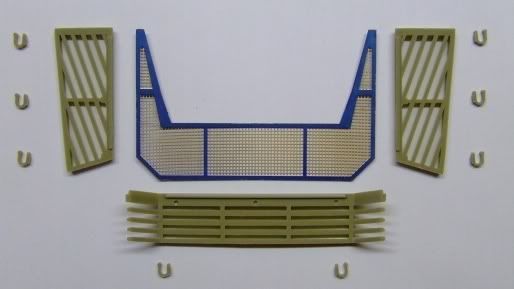

Guess what was in the mail? YES! The Airwaves PE set for the Merk II was waiting on my bench for me this morning, and I was not about to let the grass grow under my feet. I was VERY impressed with the quality, the parts appear anodised to create relief. Here they are, along with the Eureka XXL towcables set I laid in months ago:

![]()

" border="0" />

" border="0" />

I'm not sure how many bits I'll be using. I really only wanted the basket grill! The grills for the hull vents are beautifully etched but would require me to grind away the exising detail, and I really can't be bothered. The ammo can holders are possible users, though! We'll see... Must get some single-edge razor blades to fold with. There are even sets of individual foundary numbers -- how you're expected to trim and apply them I don't know!

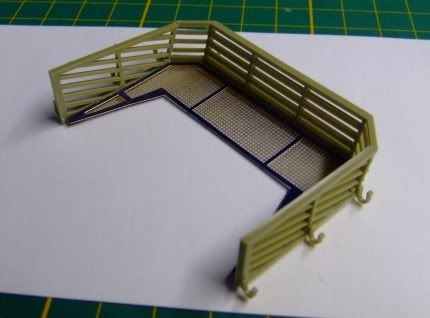

Well, I trimmed out the plastic parts for the basket and the cable clamps and got everything filed up smooth. Here's the parts layout:

![]()

" border="0" />

" border="0" />

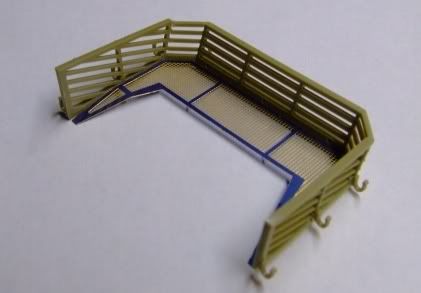

I wish I could say assembly was easy but 'fiddly' is a good word for it. I spent a while getting the plastic-to-metal bonds firm, then added the teensy cable holders, and re-added them as they keep falling off. The carpet ate one but Academy thoughtfully include a spare or two. The angle of the mating faces between the three plastic parts don't match, and needed filing, and the metal floor does not quite fit the contours of the rear plastic part. But I got it all together:

![]()

" border="0" />

" border="0" />

Naturally, at this point I dry-fitted the basket to the turret, and found out it didn't. Fit. It took a bit of pondering to figure out why, but the PE was meant to be bent. I realised this when I compared it to the plastic part, which is molded with the narrow arms of the floor inclined downward to clear the turret flanks. This does not appear in the instructions for Academy or Airwaves, and the side panels of the basket walls are molded with a straight-line locator flange which would inhibit the fit of an inclined floor anyway, unless the floor was meant to be fitted from below (which makes no sense, as the flange would then be visible). What to do? Fortunately, the plastic-to-metal bond is not so strong that it wouldn't readily part if flexed with a knife blade, so I parted the floor from the side panels, then pared away the flange back to the fold point of the PE. When it was smoothed back, I reattached the PE with a subtle bend introduced simply (and remounted half the cable guides which fell off in the process). Note the bend, below:

![]()

" border="0" />

" border="0" />

The subassembly was then dry-fitted and found to match up acceptably well. I went ahead and superglued it into place on the turret:

![]()

" border="0" />

" border="0" />

This round of work added another 12 parts to the model. Remaining structures include all topside MGs, a few top and tail-end fittings, tow shackles, a few bow fittings, mount the rear hatch, the skirts and join the hull. Overall, this model has generally built easily, so I'm optimistic I'll be getting her into the paintshop in the near future.

I'm glad to be back in the saddle here, after more than three months out!

Cheers,

Mike/TB379