When I started this WIP I was determined to show the good, the bad, and the ugly. I still am, and here is some bad for you.

I snapped off the knee. I did it not just once, not twice, but three times. After the third time of fixing it I said, "(Bleep) it. I will fix it once I get closer to paint."

It happened earlier on in the build and always when I was working on the transom. It's crazy. No matter how careful that I tried to be, I invariably, unknowingly, had the beak resting on my leg and then... snap! It's not the worst thing in the world, it just creates more work. So for anyone building this kit, be advised.

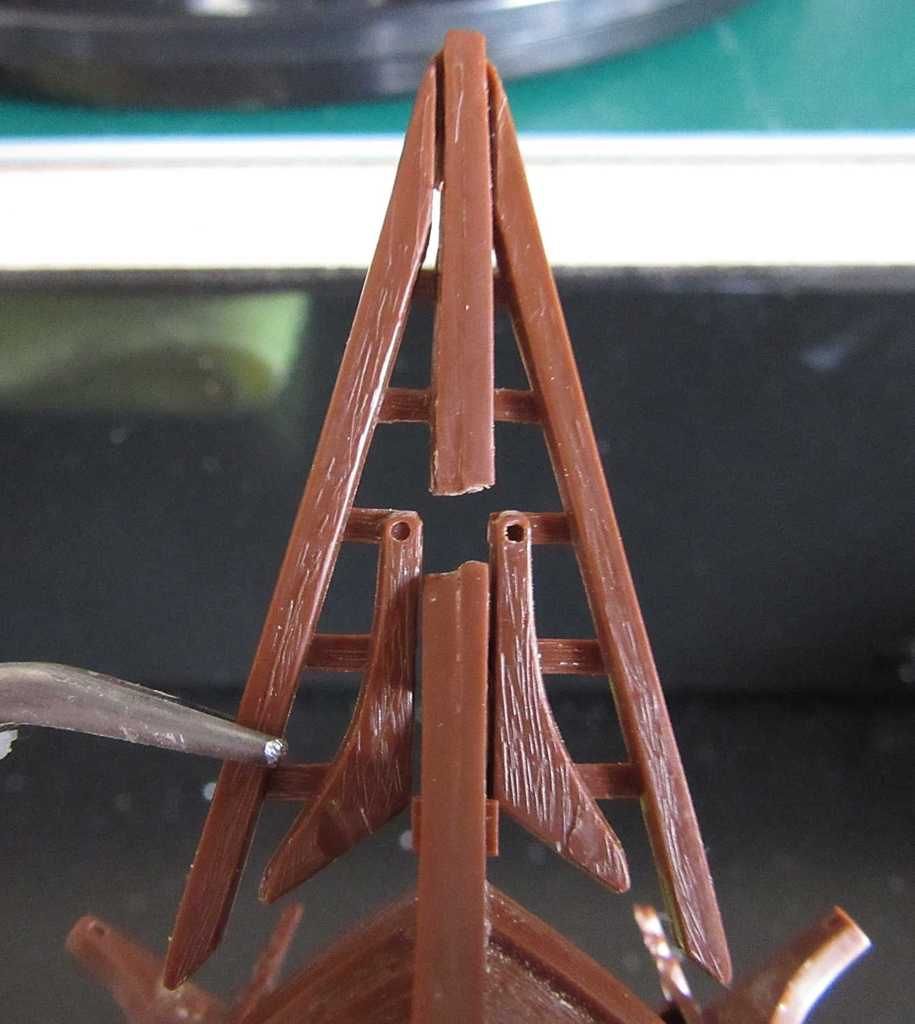

With this repair I did something different. Rather than just gluing the knee to the hull like I did before, I instead glued it to the triangular piece first. I did it this way because I was able to align the broken piece better with it resting into the other.

Below: The problem as viewed from underneath and looking up.

Below: Glued in.

Below: Some plastic surgery using CA as filler. It's not perfect, but close enough for me.

And that is that.

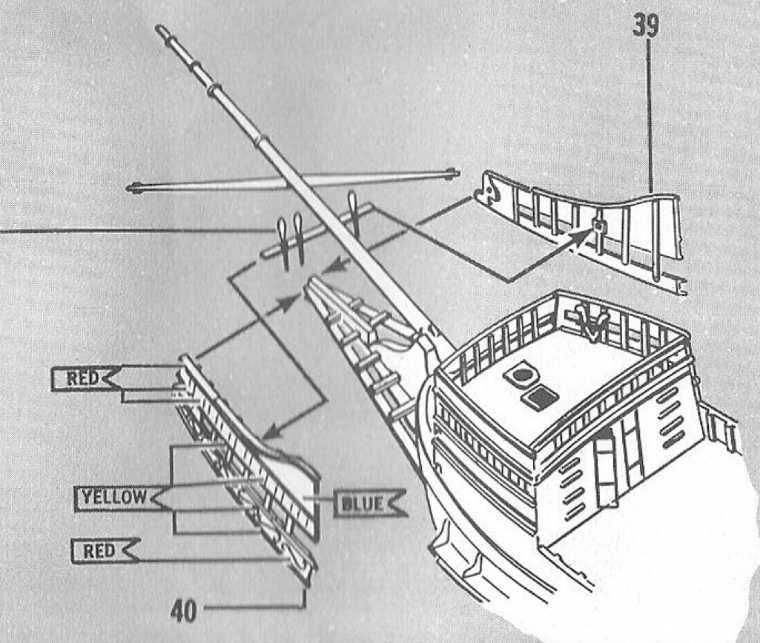

This assembly is tricky to align correctly and if you get wrong, it just won't fit, nor look right. This is especially true when installing the beakhead rails. If these first steps are wrong, the rails won't fit right, and the rails are a very noticeable part of the ship. It took a lot of test fitting, but I think that I have it correct now.

My next dilemma is if to install the rails now, or after paint. I have to ponder that more. I am leaning to after. It will make painting easier. The downside is that it will be a little harder to get nice solid joins.

So, I have the rails to consider, then mask the transom windows, then prepare for paint.

Anyway, this is where this build stands. As a reference, the beakhead rails are shown below as number 39 and 40.