The Bow Light

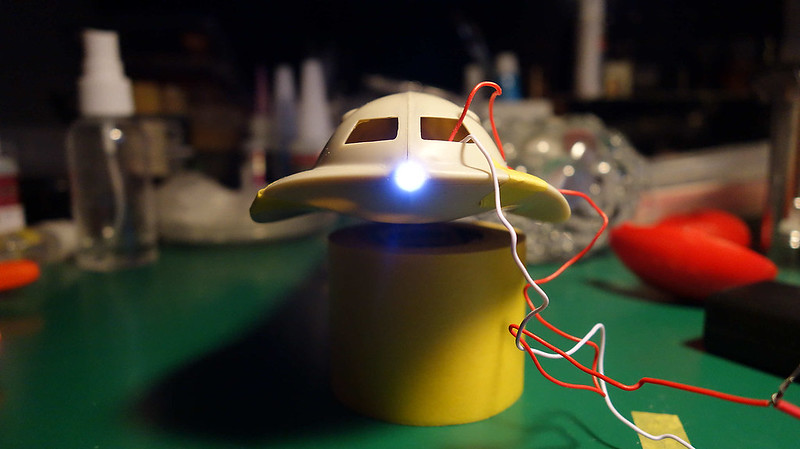

I was not sure if my 2 AA 3 volts battery pack could handle a third LED. So, I ran a test. I hooked up a third LED to the pack and flipped the switch. All three LEDs lit up. Yea! I left the LEDs on for about 4 hours and I didn't see any appreciable reduction in light output. I did this again for another 2 hours and with the same outcome.

This was good news. If I can get at minimum 6 hours on two AA batteries, I am good with that. Btw--the LEDs didn't heat up at all. They were cool to the touch. That is the beauty of LED technology. They have low power consumption, and they produce little heat.

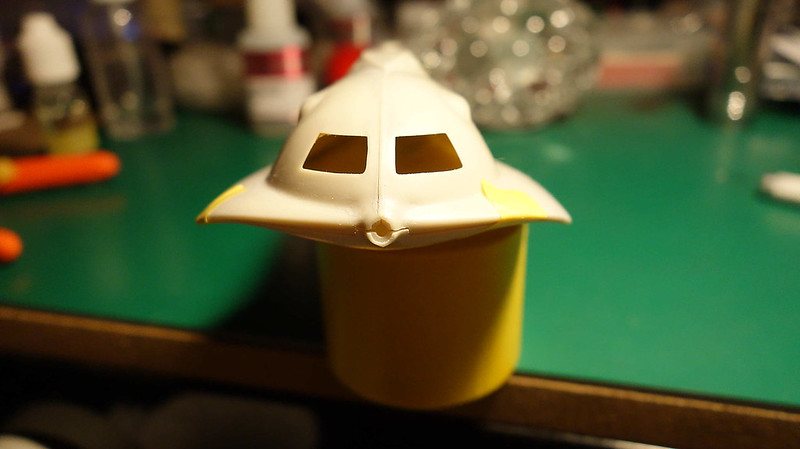

I measured the bow light port and behold... the LED size that I have will fit. This was a stroke of good luck. One thing though, I have to remove the mounting base, and I will have to open up that port some.

Below: 3M tape pulled away.

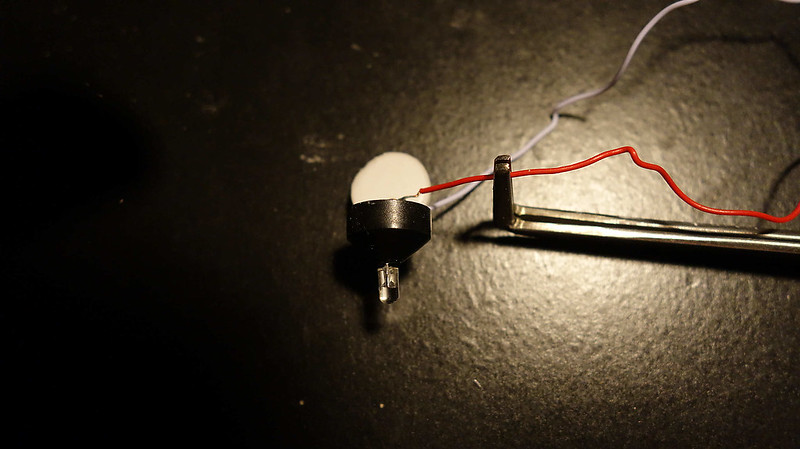

Below: How it looks from the back.

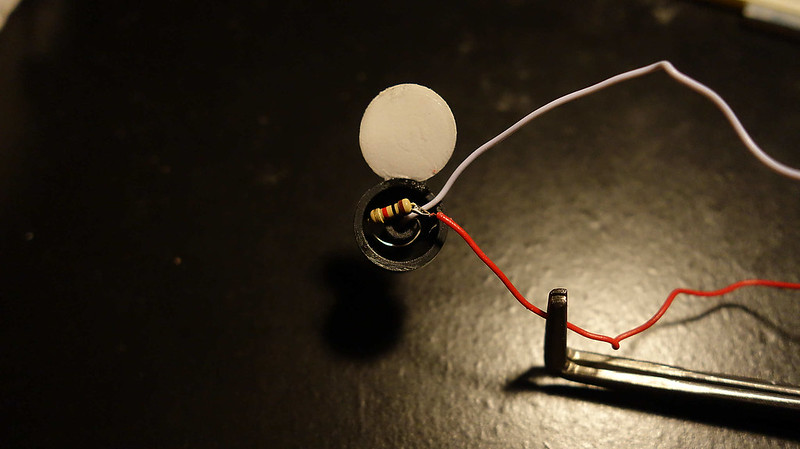

Below: Neither the resistor nor the LED would fit through the front hole. I have two options to remove that black piece. Either cut the resistor or LED off and pull the wires through. Or, cut the plastic away. I opted for the latter.

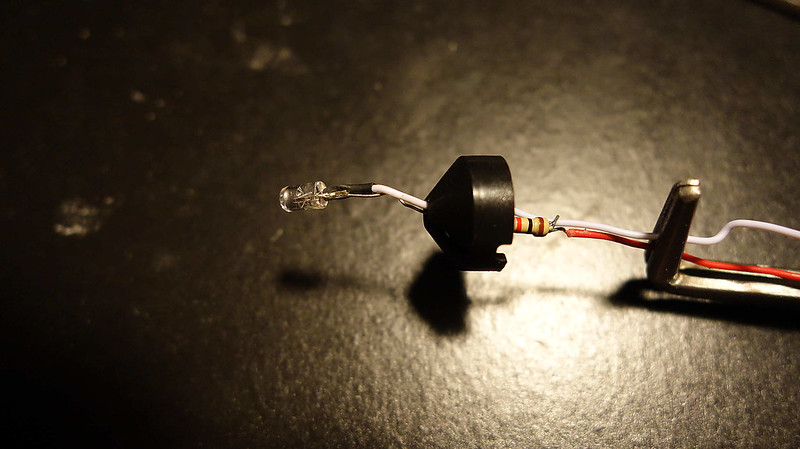

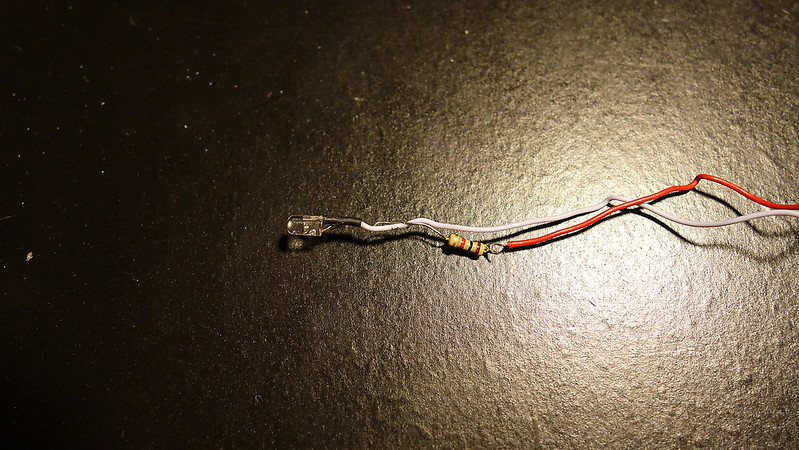

A naked LED assembly. Don't stare too long.

Below: How the light port looks before cutting. I have two ways that I could go with mounting the LED.

1. I could insert the bezel that comes with the model and then mount the LED behind it. In this case, I would not need to cut the opening much. I think that this option would drastically reduce the amount of light that comes out of the bezel. I bet it would look cool as heck though.

2. Cut away that inner flange so that the LED can come through it. In this case the LED will act as its own bezel. You will definitely get more light this way.

For this project...I need the light. Option 2 is the way that I am going.

Below: This will need some fine tuning and filler work, but you get the gist.

Lastly, here is a link that offers a nice and simplified synopsis of how to work with LEDs. The easiest way to do a simple lighting project may be by using what I have bought. The LEDs already have the correct current limiting resistors for a 3 volts power supply. You can use batteries for the power, or... buy a wall transformer that outputs 3 volts. Then--it is just a matter of hooking up the wires and mounting things.

http://www.instructables.com/id/LEDs-for-Beginners/