I do not have my next process nailed down yet but I thought it might entertain you to watch as I work through it. What I ultimately end up doing is not written yet. The basic process is "expected" to be this:

1. I will lay down a layer of putty that I can form into larger waves. This will include a bow wave. I was not able to do larger waves in my last go by using the John Wayne TP alone. That process limits you.

2. This process calls for a layer of TP on top of the first layer. From what I can tell it will do two things. Firstly, it should help to smooth out irregularities in the first layer. Secondly, it allows you to form smaller waves as well. If done properly, the two complement each other, and it can form a very convincing sea.

3. Apply the base color, the churn color, and then dry brush the foam color.

4. Apply the high gloss varnish.

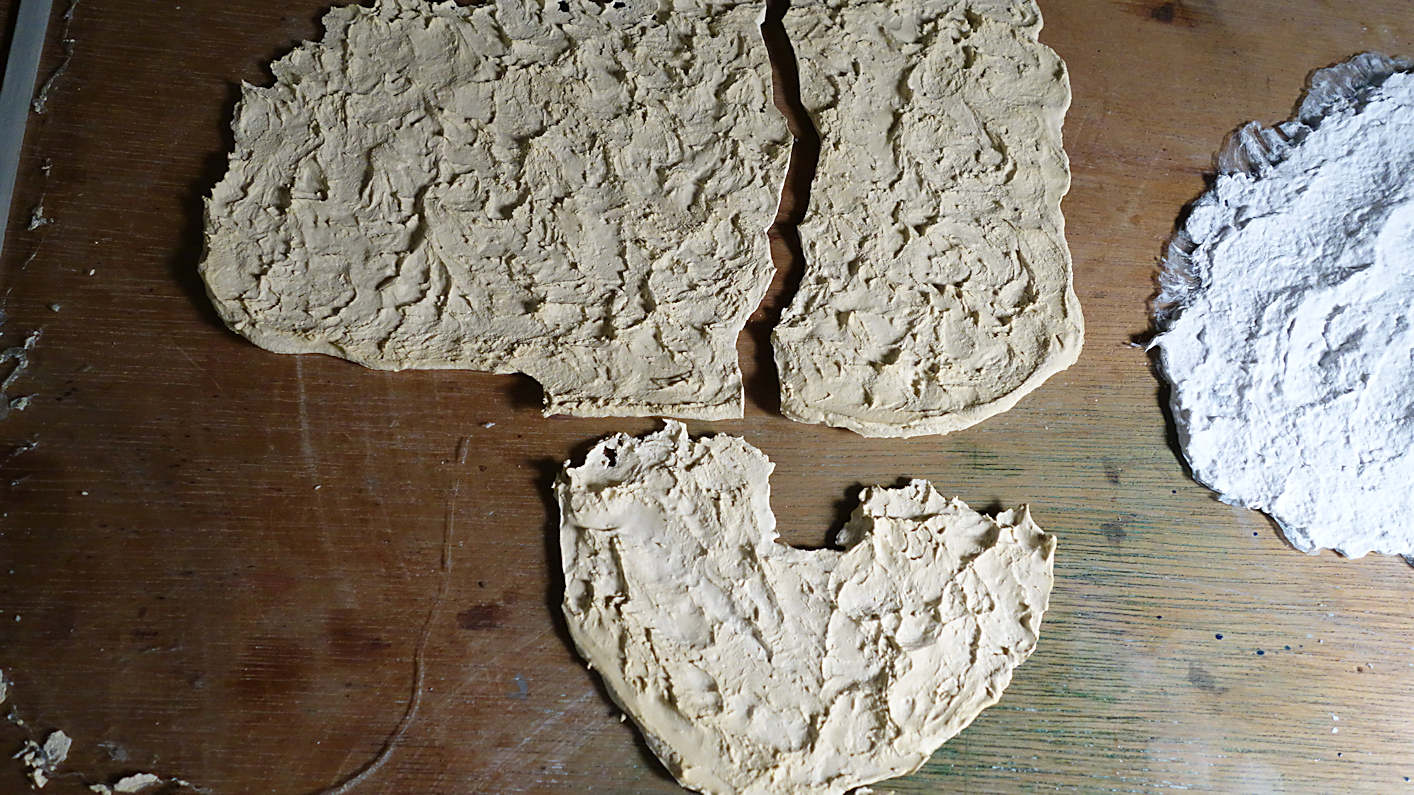

Below: While I waited for the other putty to arrive, I experimented with the first. This product is called Durhams Water Putty. They claim it won't shrink, it dries hard, it's sandable, and you can even drill it. I had worked with this stuff before and I have always thought that it might offer some hobby potential. Such as with a dio.

I mixed a batch to a thick consistency and laid it on the glass pallet. Btw--the glass is what my picture frame base came with. I knew that I'd use it for something! I mixed it thick so that it would not self-level. Manipulating it around seemed to work OK I guess, but I was so-so about it. I struggled to make waves that I'd like. Maybe with practice. This was very preliminary.

Once when it appeared cured, I was able to lift it up off the glass. It popped off is more like it. This could be problematic since I will be using it on plexi. It seems the putty needs something porous to grab onto. I also tested its snap strength. The piece snapped in half far too easily. What started as what would probably be my go to putty is not so good now.

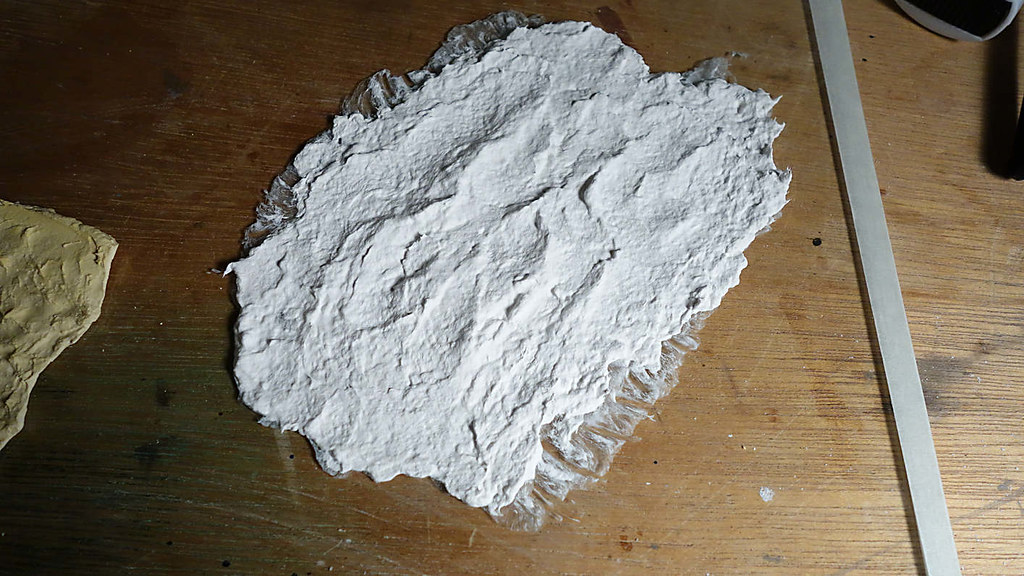

Below: The second product is called Sculptamold. They claim it is lightweight and strong. At first appearance the powder looks extremely fibrous and clumpy. I was like, "What is this (beep)." But--I had watched videos of people working with it ok. So, I pressed onward. I mixed it so it was thick and pliable. I plopped it on the glass and began working with it. "Well I'll be. This is working better than the Durhams." It formed deep waves much more readily. Once cured it seems very strong. And, it sticks to the glass like glue! If there is a downside, thus far, I'd say that it can a bit clumpy. I think that it should work ok once covered with the TP. Also--I know that this material can be smoothed out during the curing process. I did not attempt that yet. I fogot to mention that it IS light in comparison to the Durhams, or some other sort of plaster.

I see a nice potential with this. As of now--it is the stuff that I will move forward with for further testing.

So--this is a possible breakthrough to the next step. More to come as I travel along to the next boondoggle. I have to keep my hopes............ LOW.