That is a handy tip PJ. I've made thin CA applicators that fit the end of the bottle from the tip of a plastic pipette about he size of an #80 bit and its stay hollow. I wonder how thin you can go?

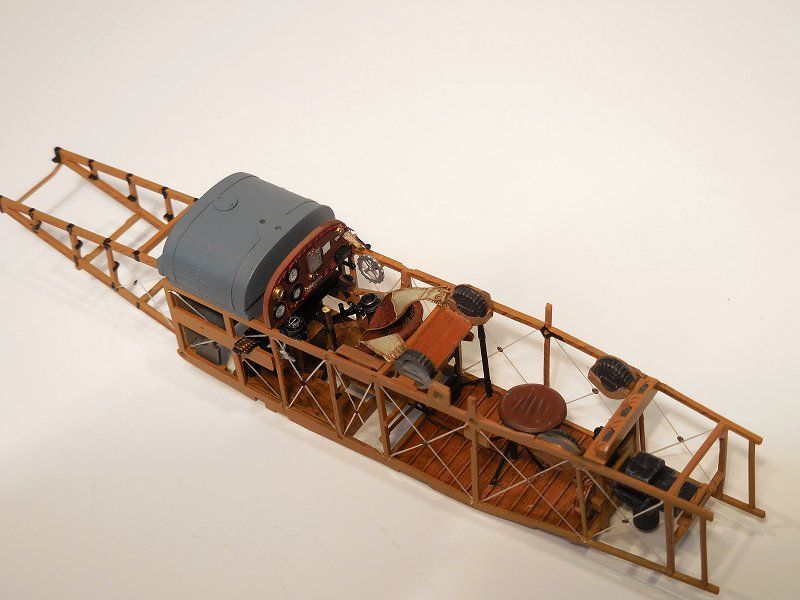

1st major sub-assembly photos and a couple of gripes.

Seems this would be a good time to make some observations about the engineering of this kit. So far I have found this to be quite different than the other WNW kits I’ve built. That is just 3 different aircraft so it may be that what I feel is superior about them may be the exception and the RE.8 is the norm.

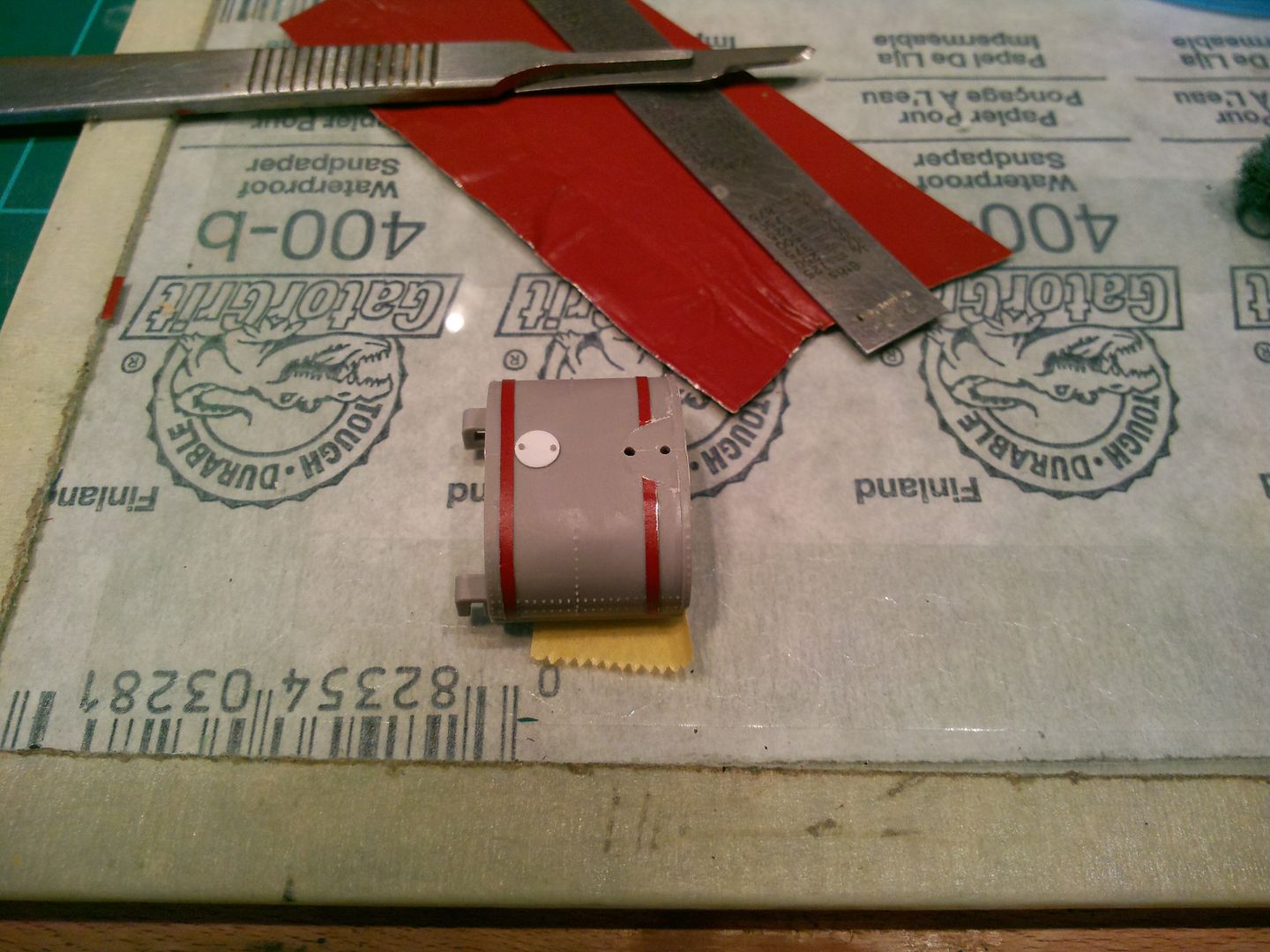

The interior frame work is very thin and fragile and molding as 2 halves puts a mold line along the edge that are fair big compared to other kits, and not just their own. Lots of delicate clean up. In the case of the tank on the interior frame, this is molded as 2 halves side by side. The seam runs down the center across some very fine detail. This tank is exposed when the fuselage it put together so there isn’t any, “Oh well, that won’t be seen once all buttoned up.” The easiest thing to do was sand it all clean, fix he seam and re-make the detail. Given the size and shape of other parts of the kit I would have though it could have been down as a top and bottom half. Like I said, no clue what dictates that kind of decision. In the end not a big job and more of a head scratcher.

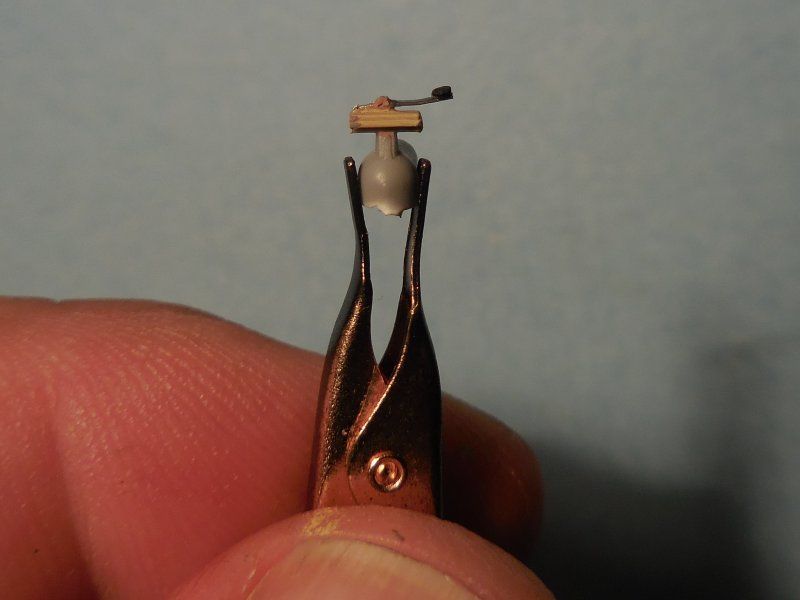

I reworked the telegraph key that was just a little layered chunk of plastic with a round thing for the end of the key. Some spare PE fret and a slice off a .3” did the trick.

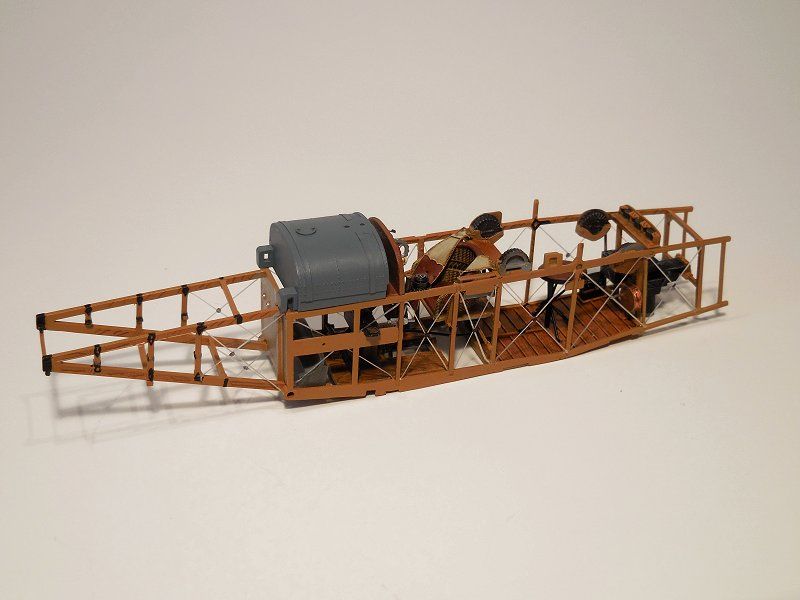

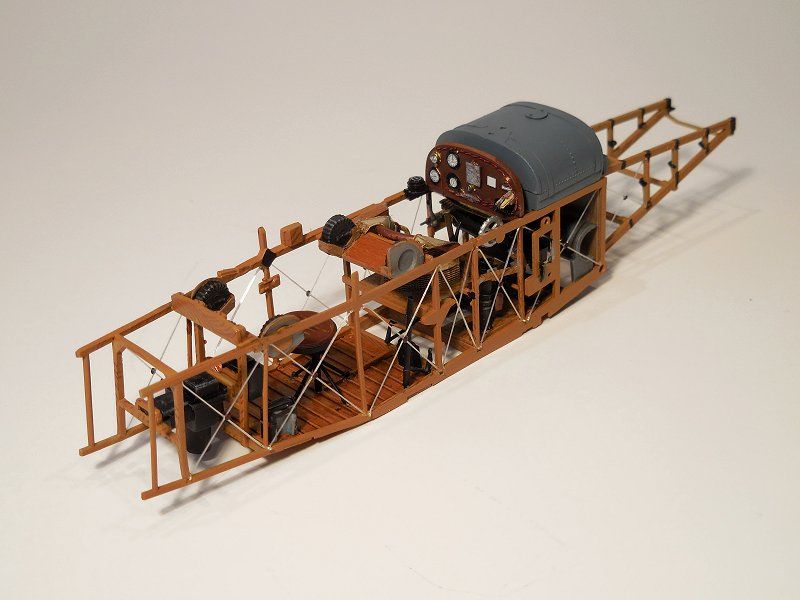

Here’s the interior to go into the fuselage. More stuff will be added later for the “passenger” as the instruction refers to the guy in the back. Some how I don’t think that guy is kicking back waiting for the flight attendant to bring more peanuts when there’s an Albatros hot on their tail.