I got frustrated with this build due to the very poor fit of the exhaust cone, and had to let it sit for awhile while I put it on the back-burner of my brain and let it simmer for a bit. The gaps and poor fit were something that I hadn't experienced on my previous two builds of this same kit, so I was actually ready to throw it in the trash. But, then I read some of the other posts in this Group Build where others had had worse fit problems than this, but they persevered, and finished what they started. And that inspired me to get this one finished. I ain't gonna let a piece of plastic kick my butt! That just ain't the American/Marine Corps way, by golly!!

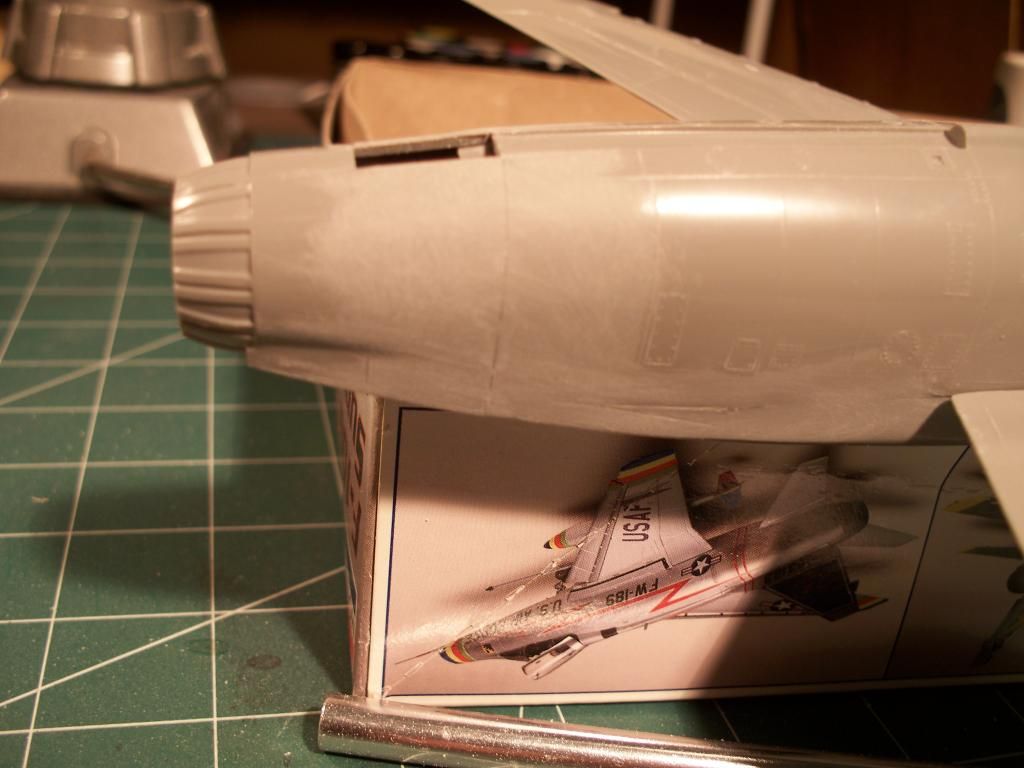

So, I finally pulled the kit back to the bench tonight & glued the exhaust cone on. And, as you can see, lots of gaps and a very poor fit to contend with, but how?

.

So, after much consideration about what to do about the gaps and very poor fit, I decide that, regardless of how I approached the issue, the horizontal stabilizers were gonna have to come off. So, with a rarely-used razor saw, I performed my first plastic surgery on my F-100.......

Not too bad. I thought that the razor saw would take off more plastic than it did, but my assumptions were way off base; very little plastic was removed. I made sure to mark the stabilizers once off to make sure that I put them back on the correct sides upon re-installation.

Not too bad. I thought that the razor saw would take off more plastic than it did, but my assumptions were way off base; very little plastic was removed. I made sure to mark the stabilizers once off to make sure that I put them back on the correct sides upon re-installation.

.

And so, after a lot of gap-filling with super glue and accelerator, plus using some .005" sheet plastic for the wider gaps, I finally got it looking decent. I used a 150-grit sanding stick to get it this far. Quite a bit of raised panels lines were lost to this. I'll worry about replacing those later on.

Although it still looks as though the gaps are still present, they are actually filled with super glue and sanded smooth. The clear super glue gives the effect that gaps are still present. You can see in the third & fourth photos immediately above where I had to use some .005" sheet plastic to fill the wider gaps. worked very well.

Although it still looks as though the gaps are still present, they are actually filled with super glue and sanded smooth. The clear super glue gives the effect that gaps are still present. You can see in the third & fourth photos immediately above where I had to use some .005" sheet plastic to fill the wider gaps. worked very well.

.

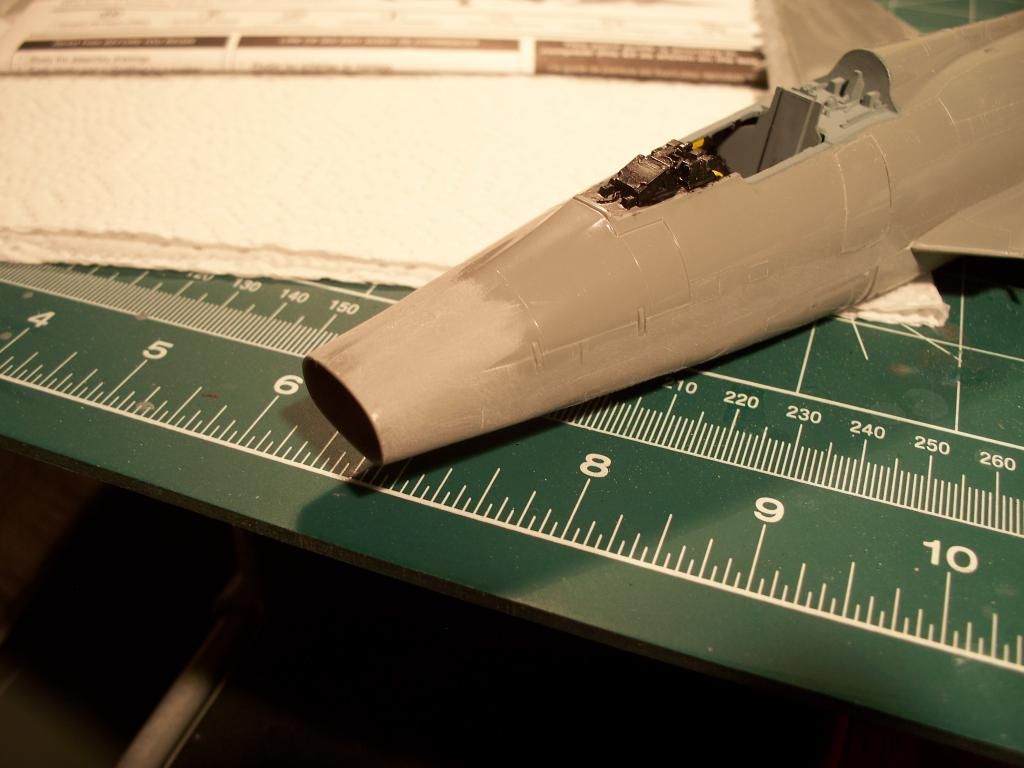

And now, for the nose cone.......

It had a few fit issues, too, but 150-grit sanding sticks will do wonders for ill fits. More raised panel lines were lost here, too, but I'll replace those later on, once I figure out how.........

It had a few fit issues, too, but 150-grit sanding sticks will do wonders for ill fits. More raised panel lines were lost here, too, but I'll replace those later on, once I figure out how.........

More to come soon (I hope!!).