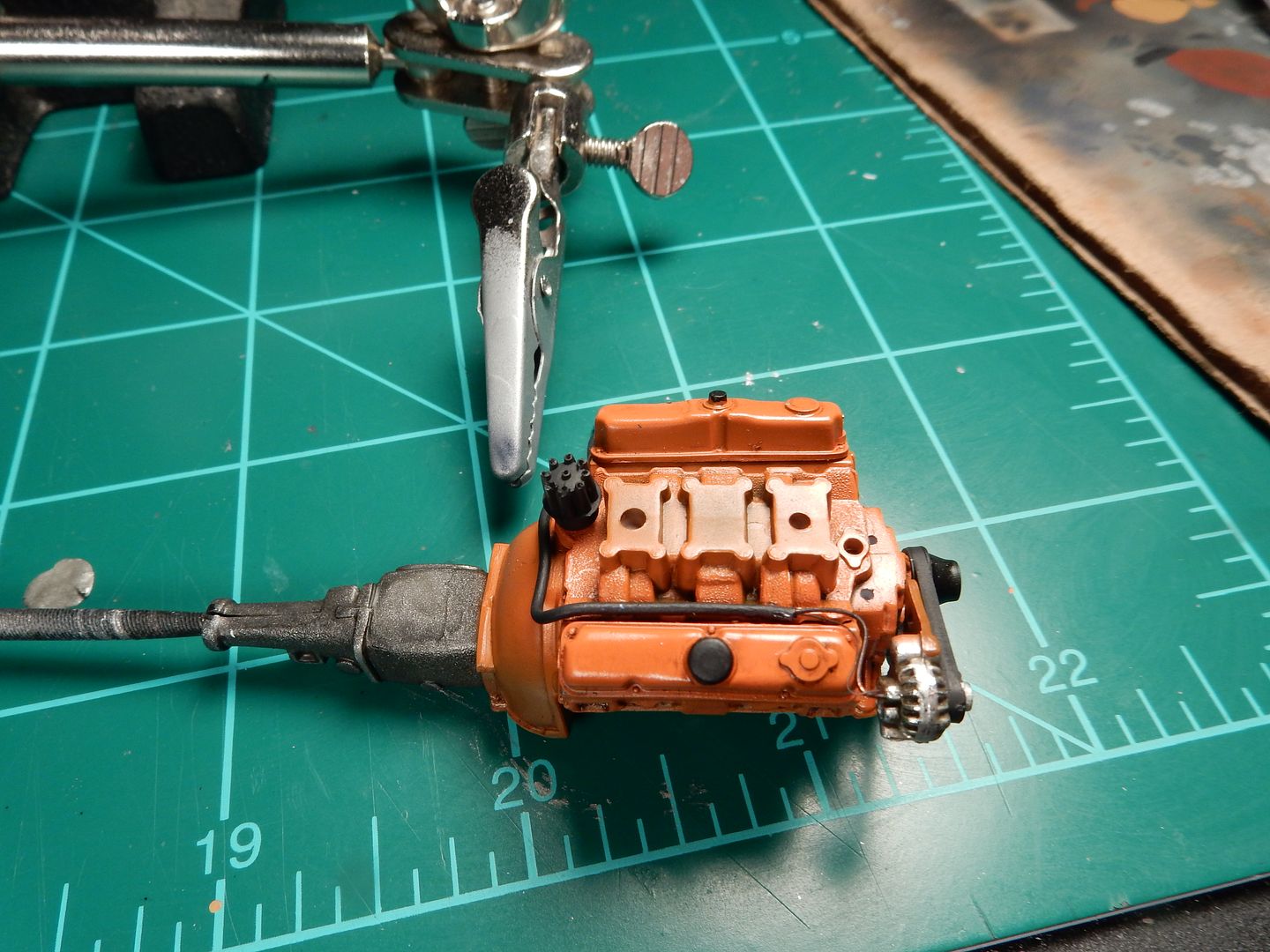

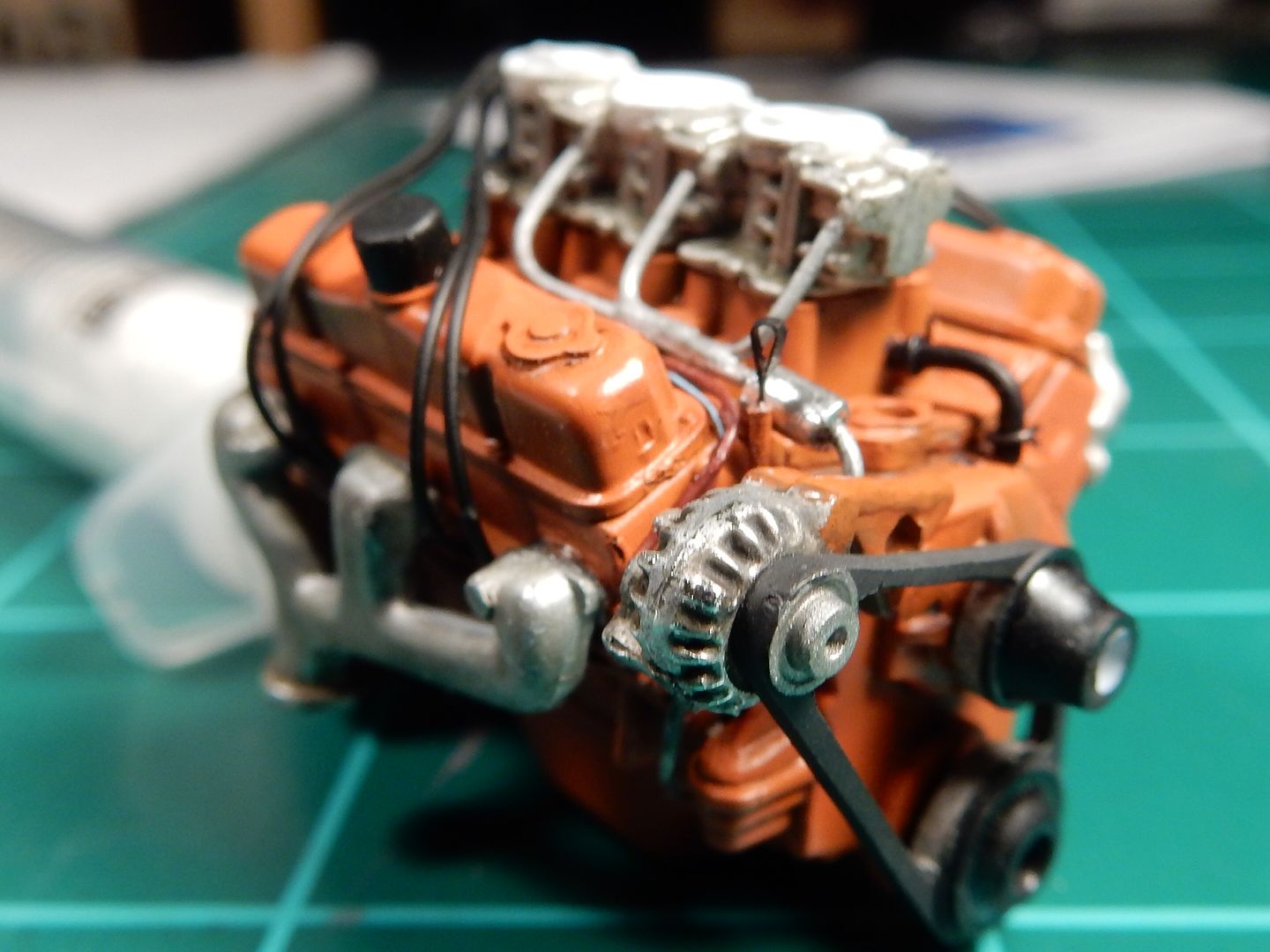

Well it's catch up time for the rest of the engine build up. This is where I left off from yesterday with the alternator and the alternator wiring to include the harness shrouding.

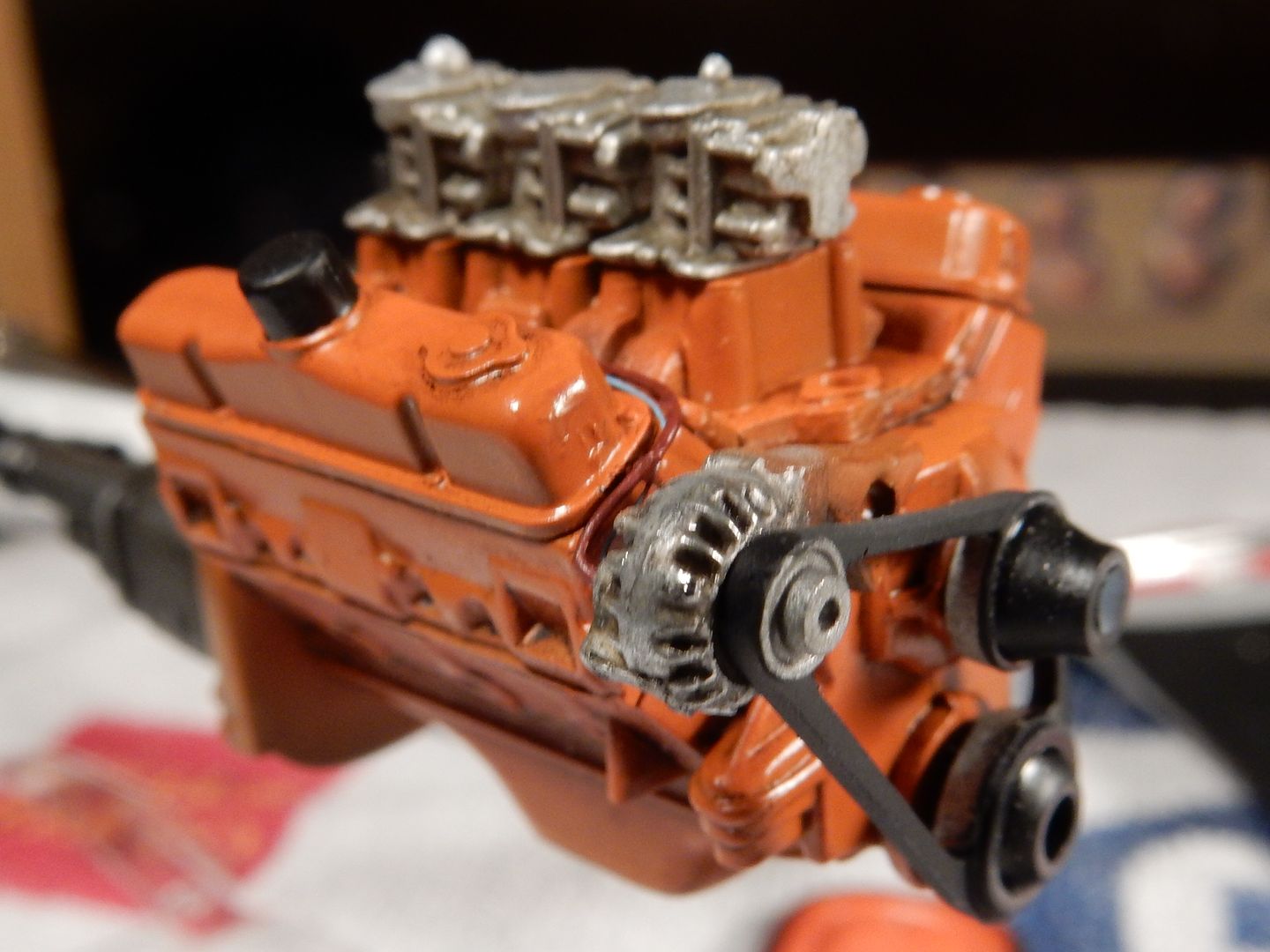

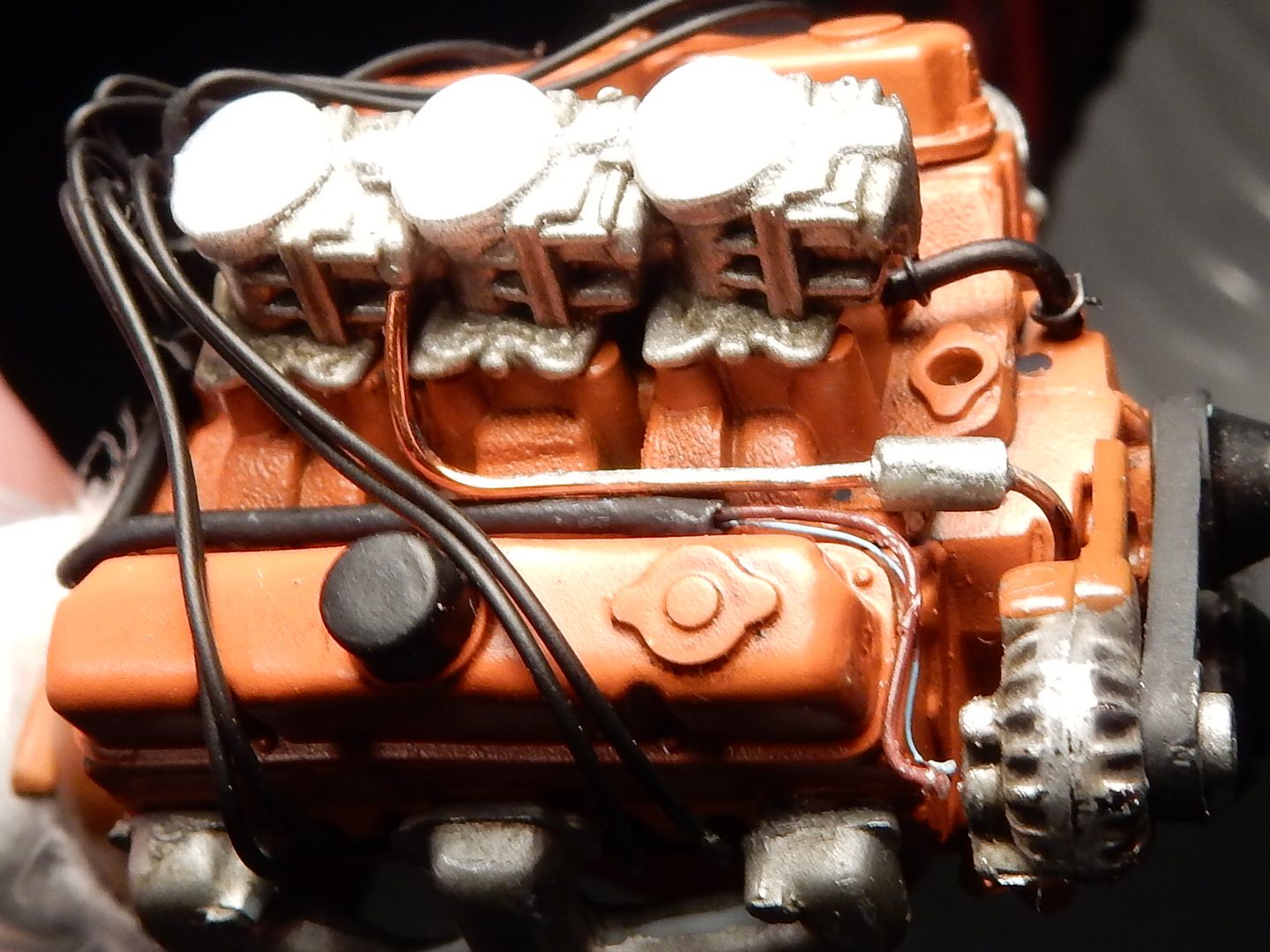

Then I painted and installed the carburetors and added a little extra weathering to the motor.

After this I installed the bypass hose from the intake to the timing cover area. This is supposed to go to the water pump area but in this case, there is no water pump to attach it to so I worked with what I had here.

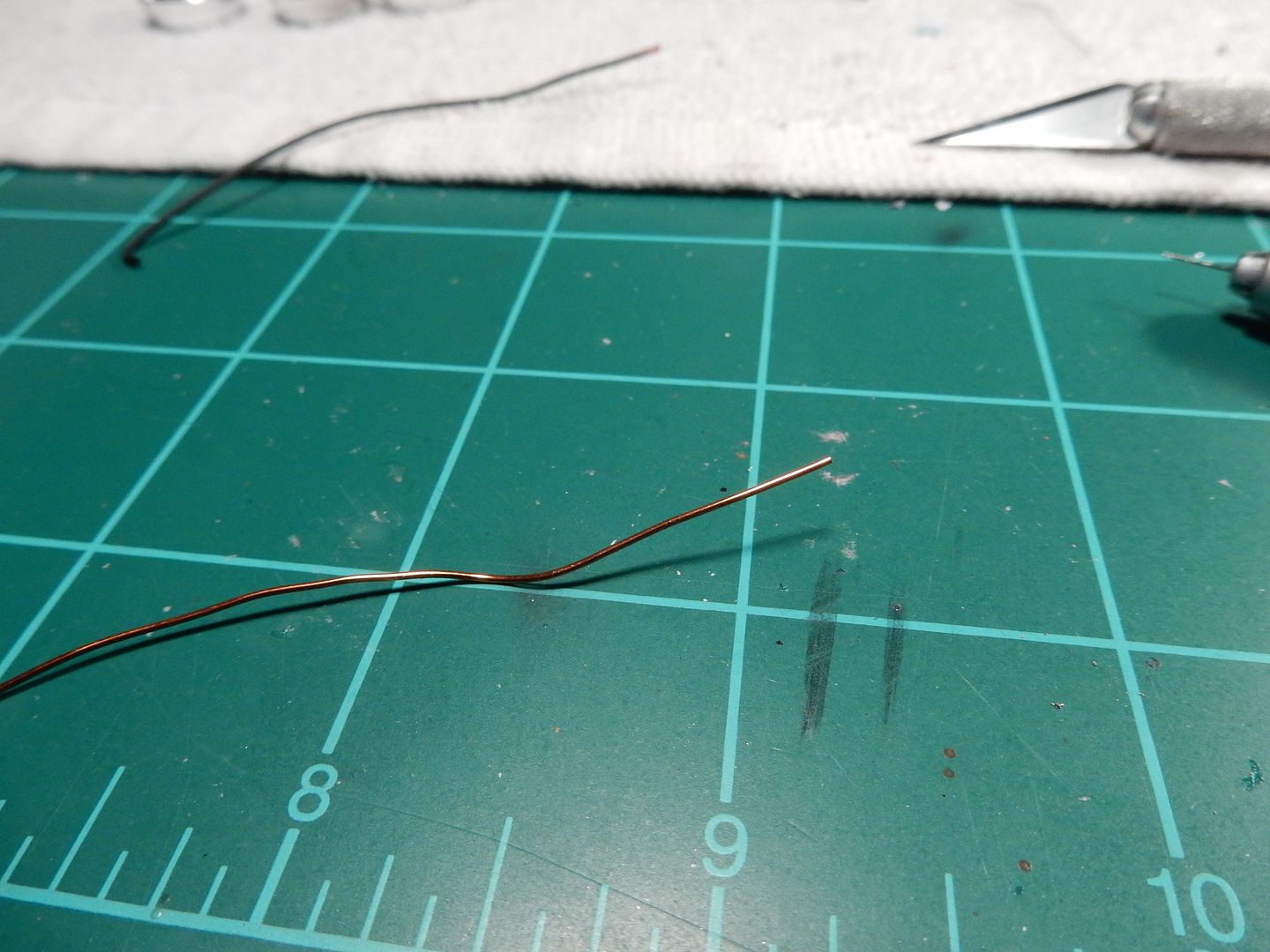

I fabricated the spring clamps out of small diameter copper wire.....

Macro pictures really bring out the worst sometimes. This isn't HALF as bad as it looks here as far as the area surrounding the hose:

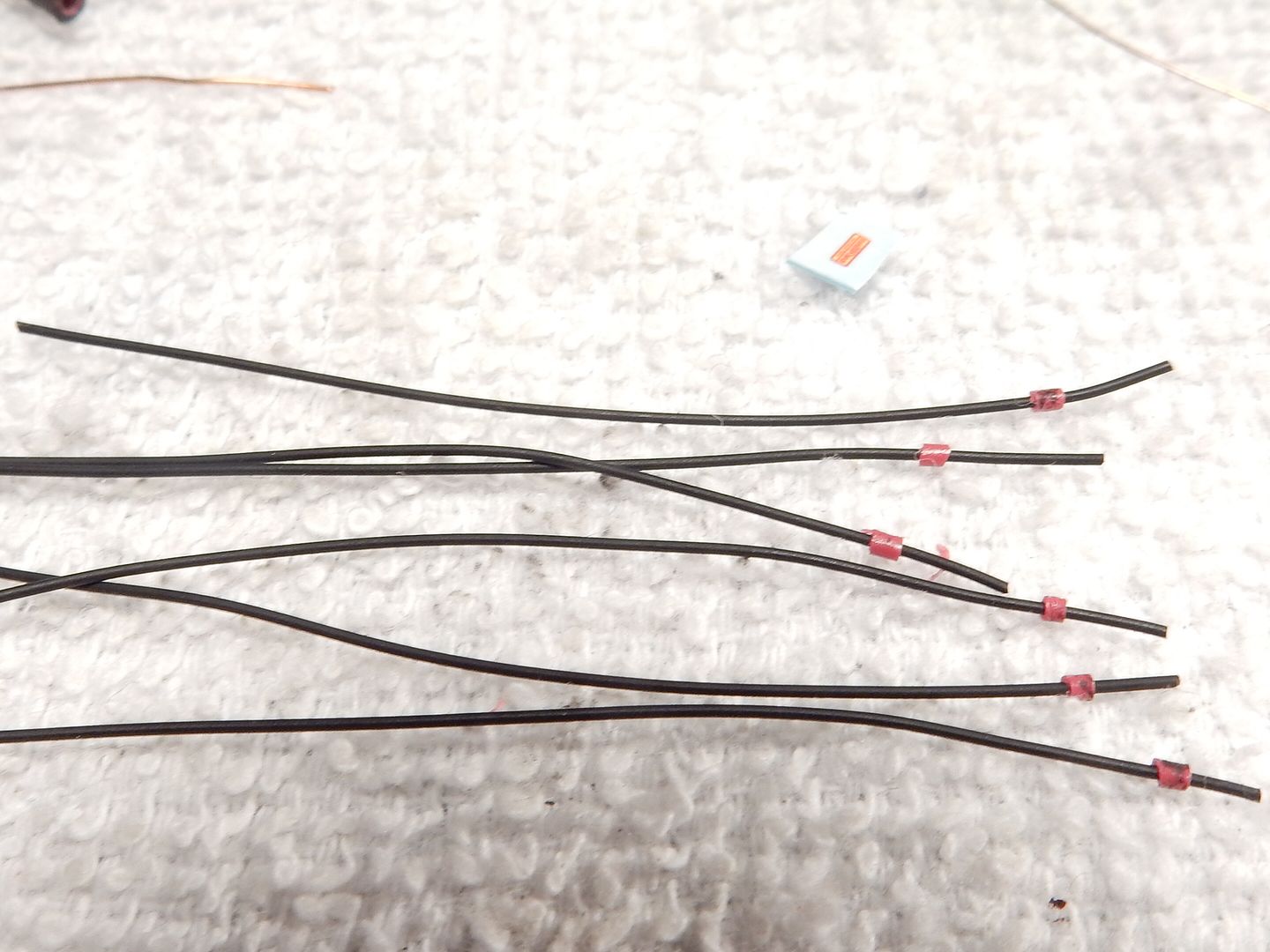

Next I started prepping the heater hoses and made clamps for those. I'll post installation pictures later after I've taken care of the rest of the detail surrounding those but for now here are the hoses:

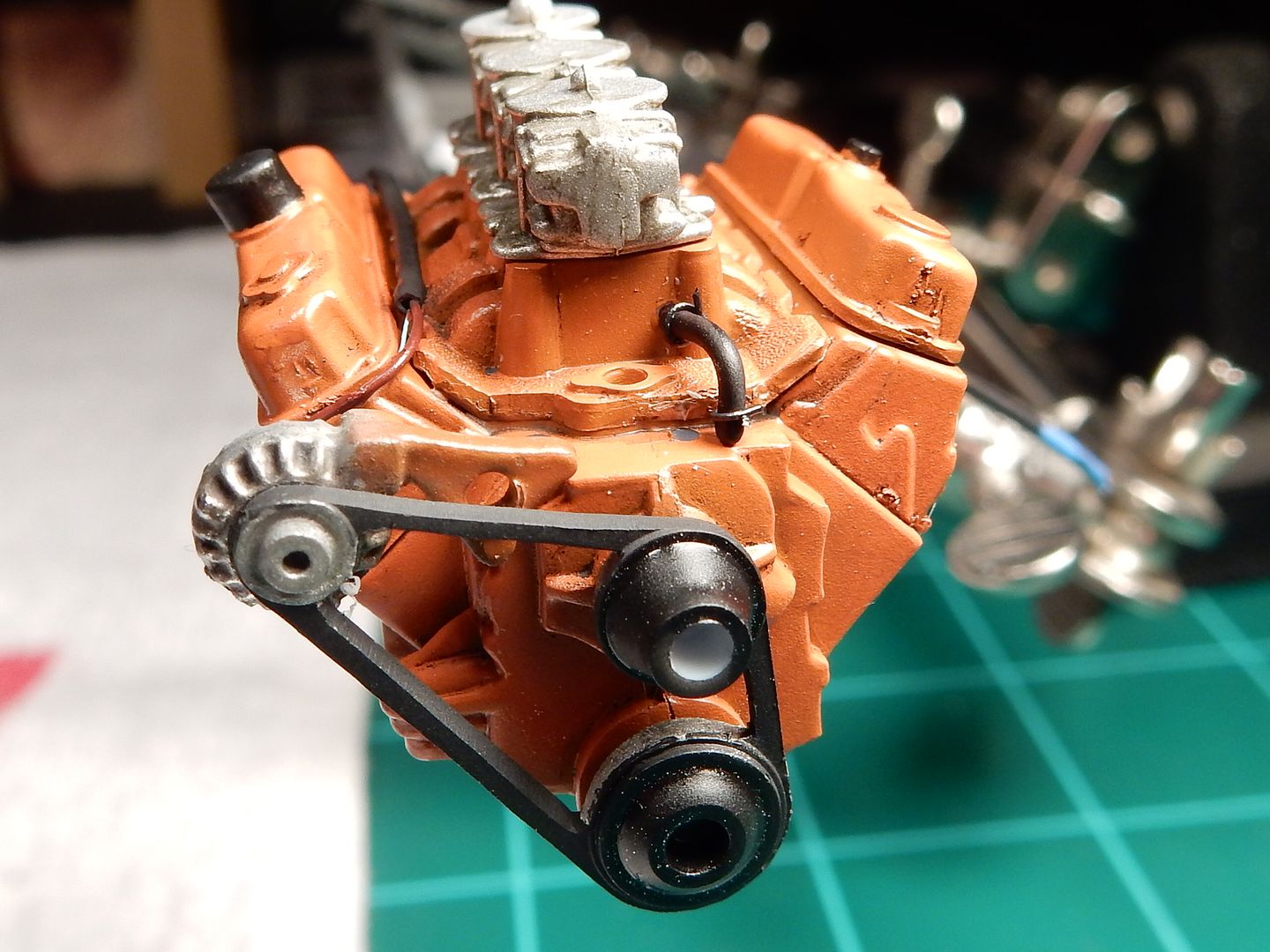

Then I started prepping the engine for ignition wire installation using Lex's Scale Modelworks colored ignition wire:

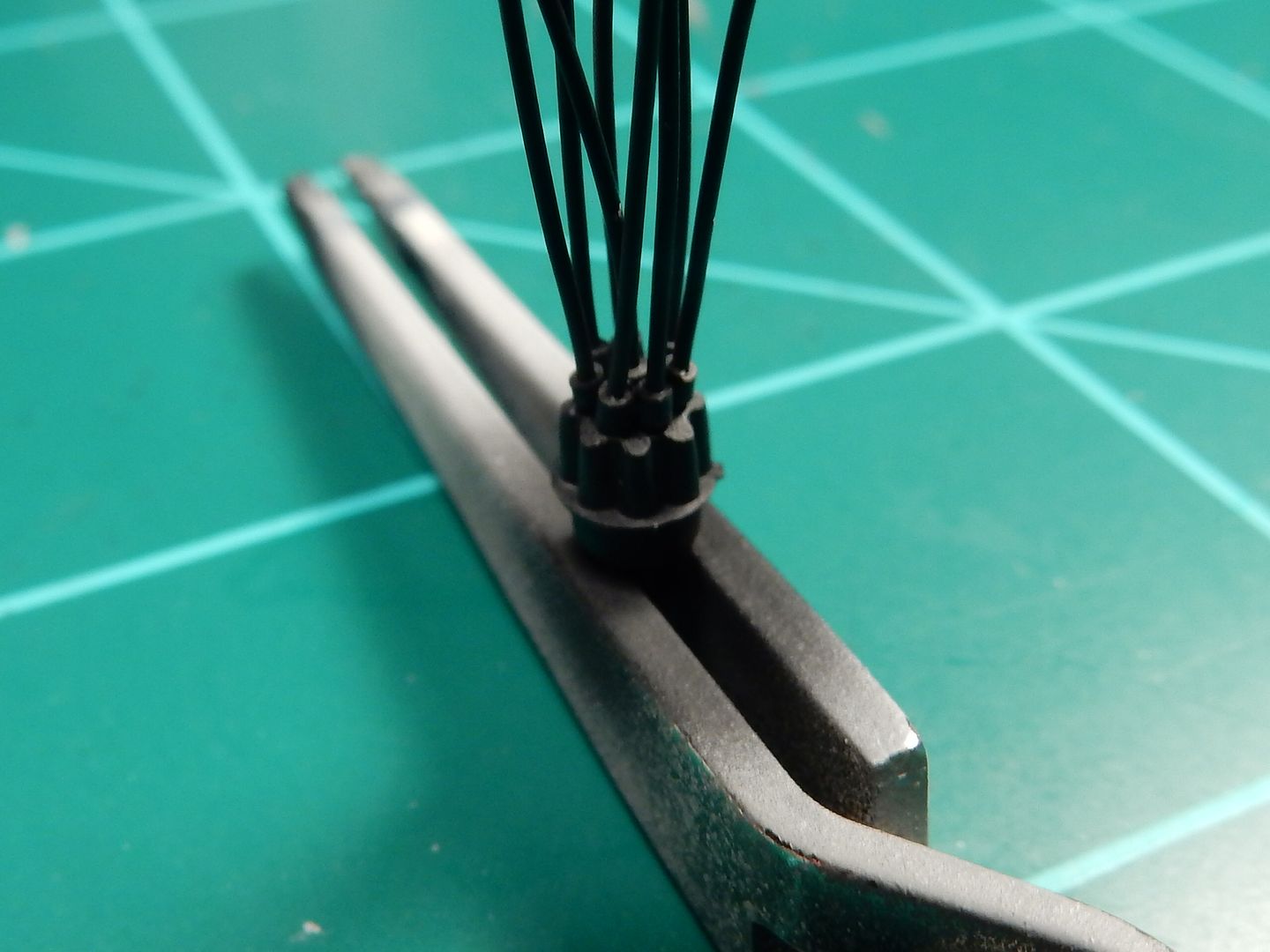

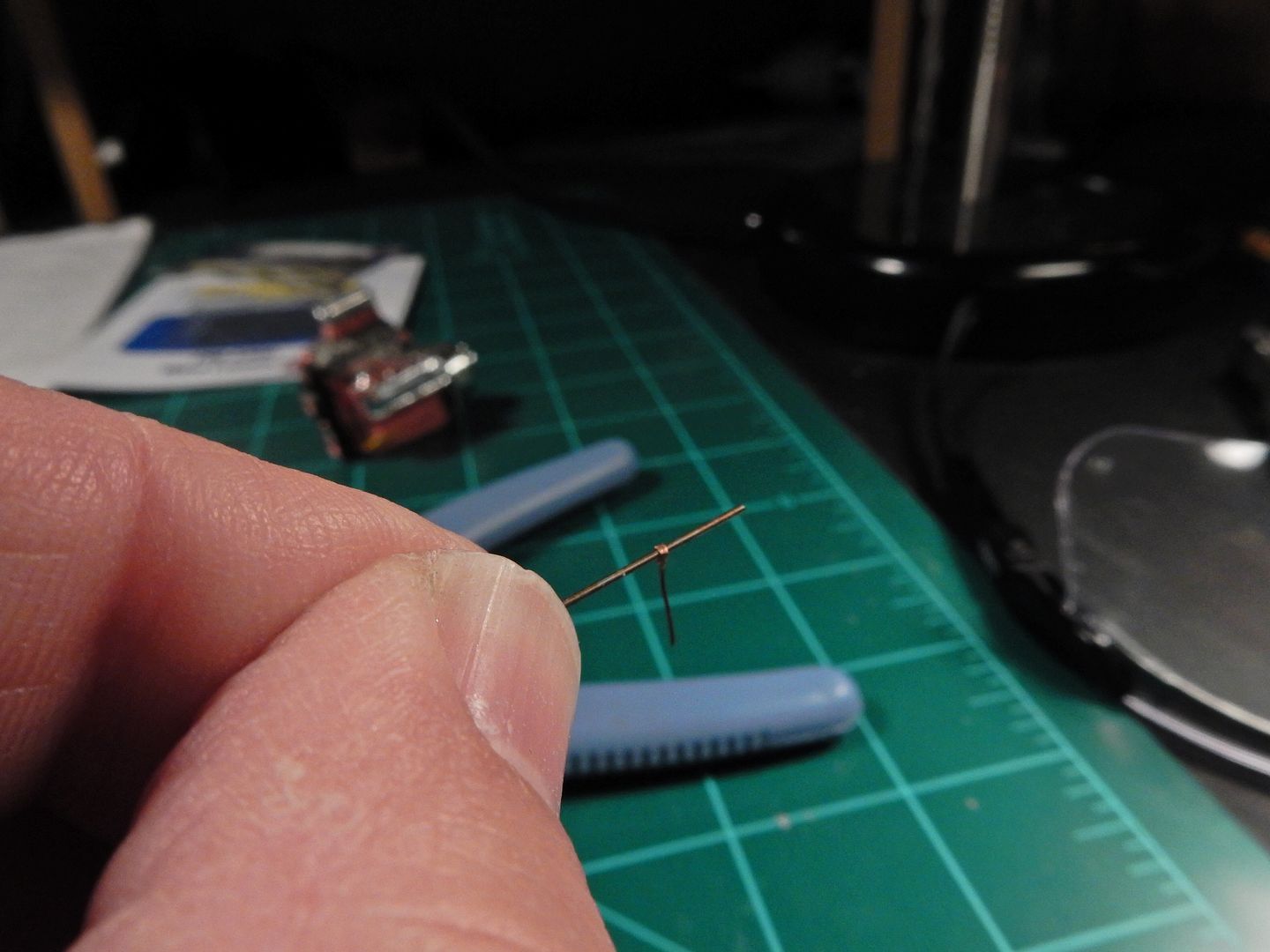

I got a tip from Fred (who you all will get a chance to meet here) on cutting wire insulation sections and sliding it over the wire to replicate ignition wire boots:

Then I painted the boots, drilled holes in the distributor cap and adhered the wires into the cap with super glue gel.

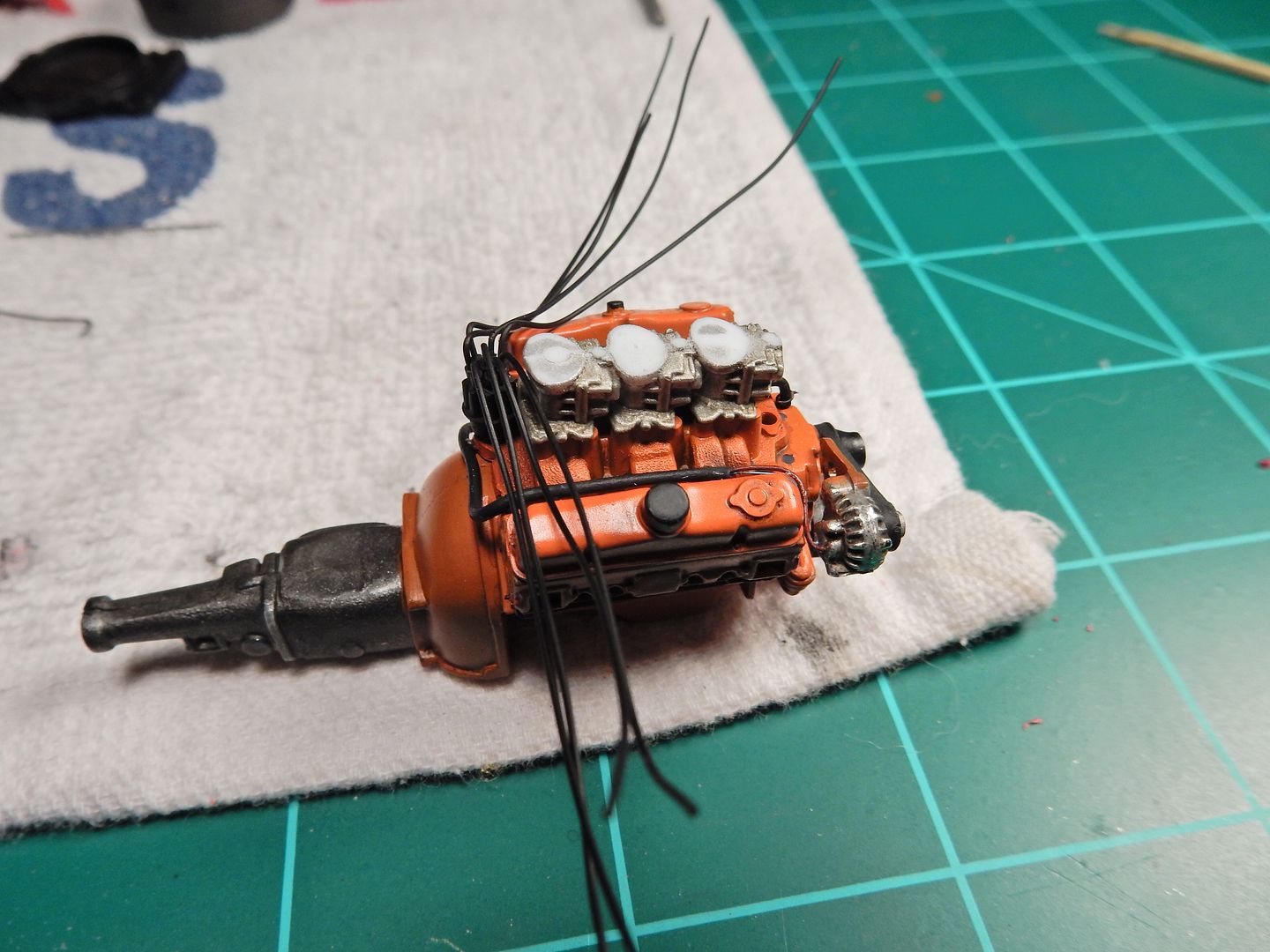

Here I installed the distributor into the engine and separated the wires out for routing:

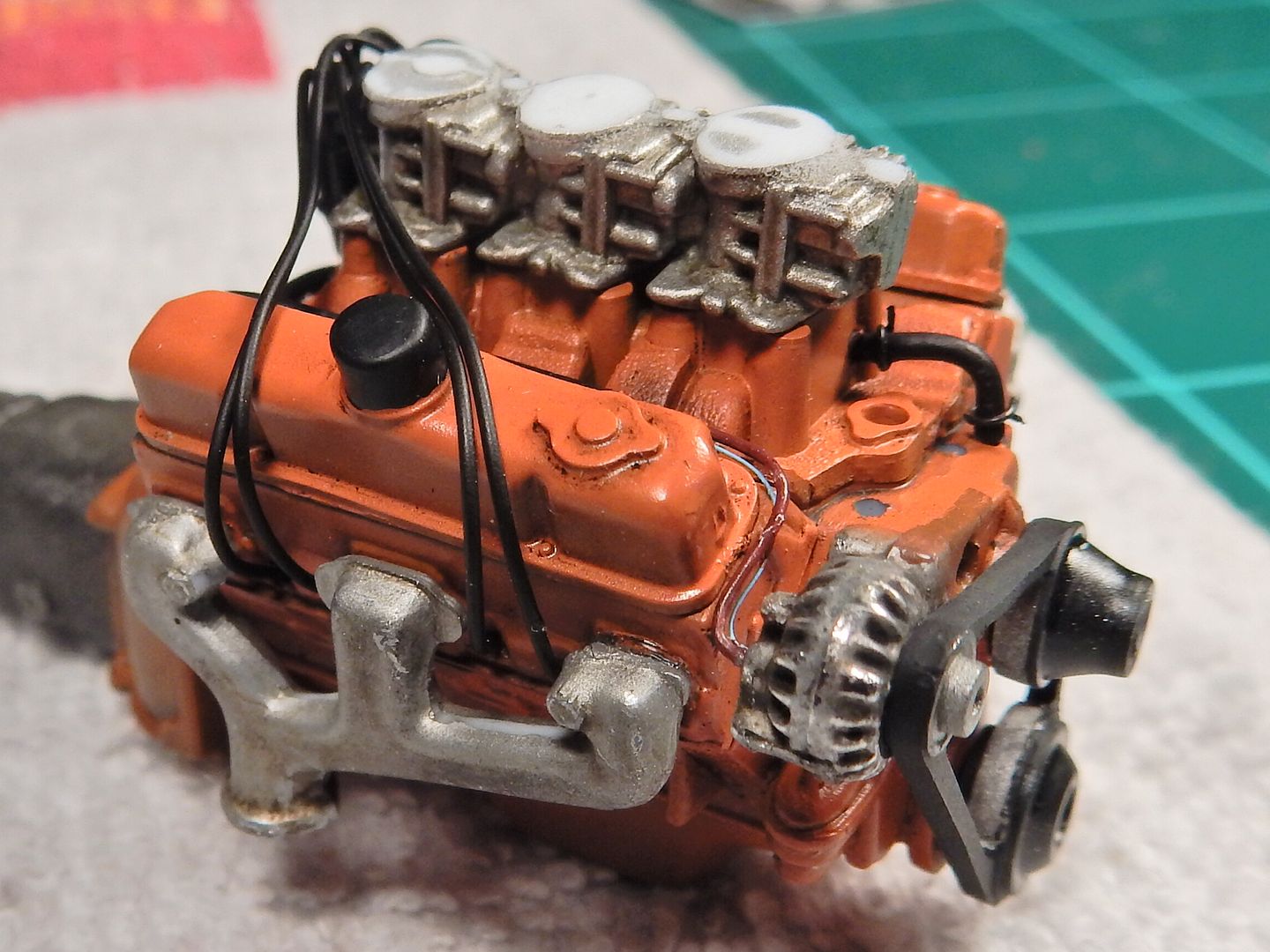

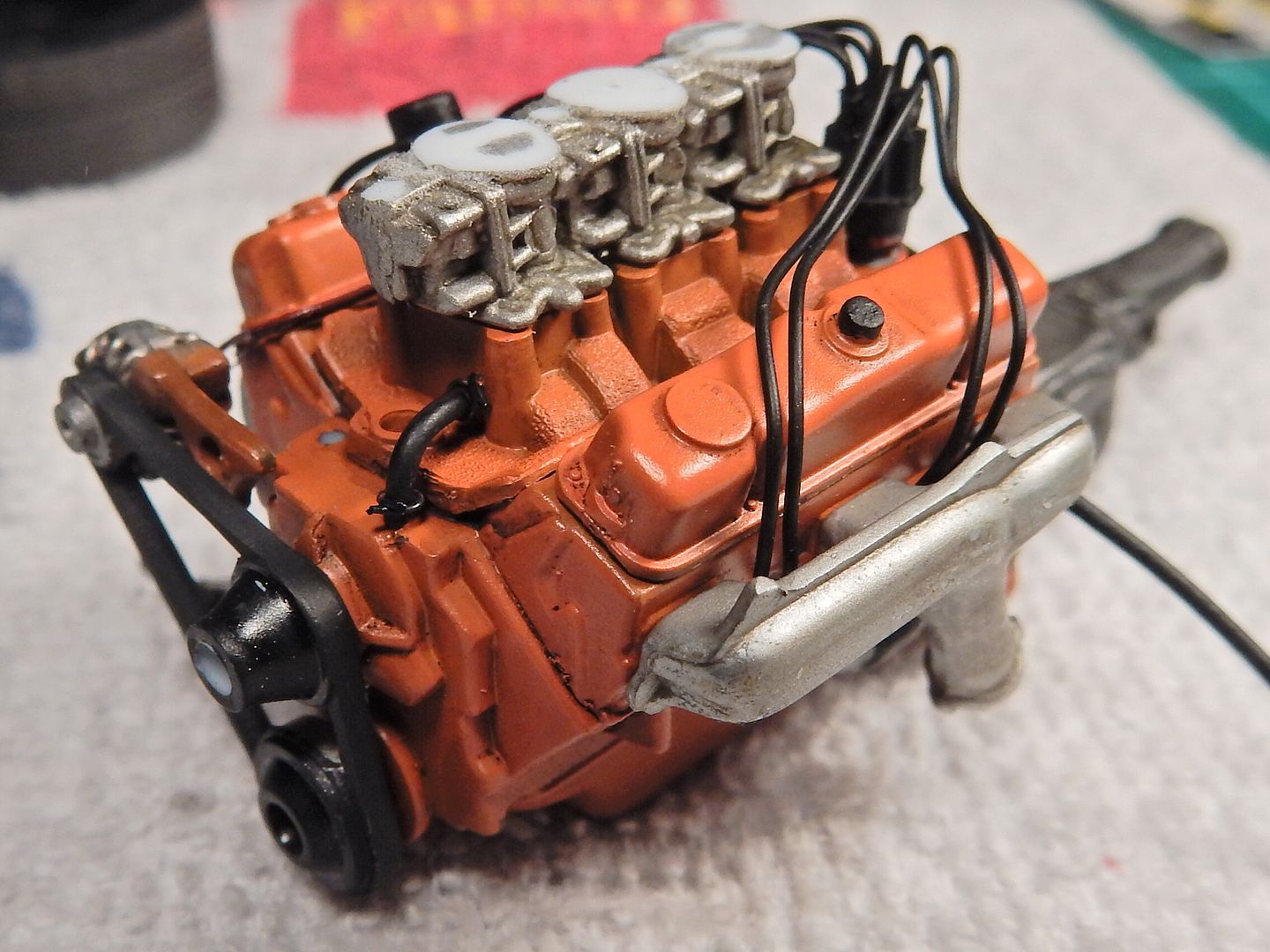

Here we have 'em routed and after drilling holes in the cylinder head, installed into the head.

After this came the fuel inlet line that I formed out of copper wire. The fuel filter is a piece of round resin stock that I had cut to the length of a fuel filter and drilled a hole through. I then slid it up on the wire to the approximate place where the fuel filter is supposed to be and adhered it with super glue. Here is a test fit between the rear carburetor and the fuel pump:

I then beveled two lines out of the same diameter copper wire to merge into the main fuel inlet line and bent them at a 90 degree turn to route to the first two carbs.

Test fit of the two lines to the carburetors....

While we are working on the fuel line I decided to install an engine oil dipstick in this thing too.

Here's what we start with for that. A piece of copper wire here:

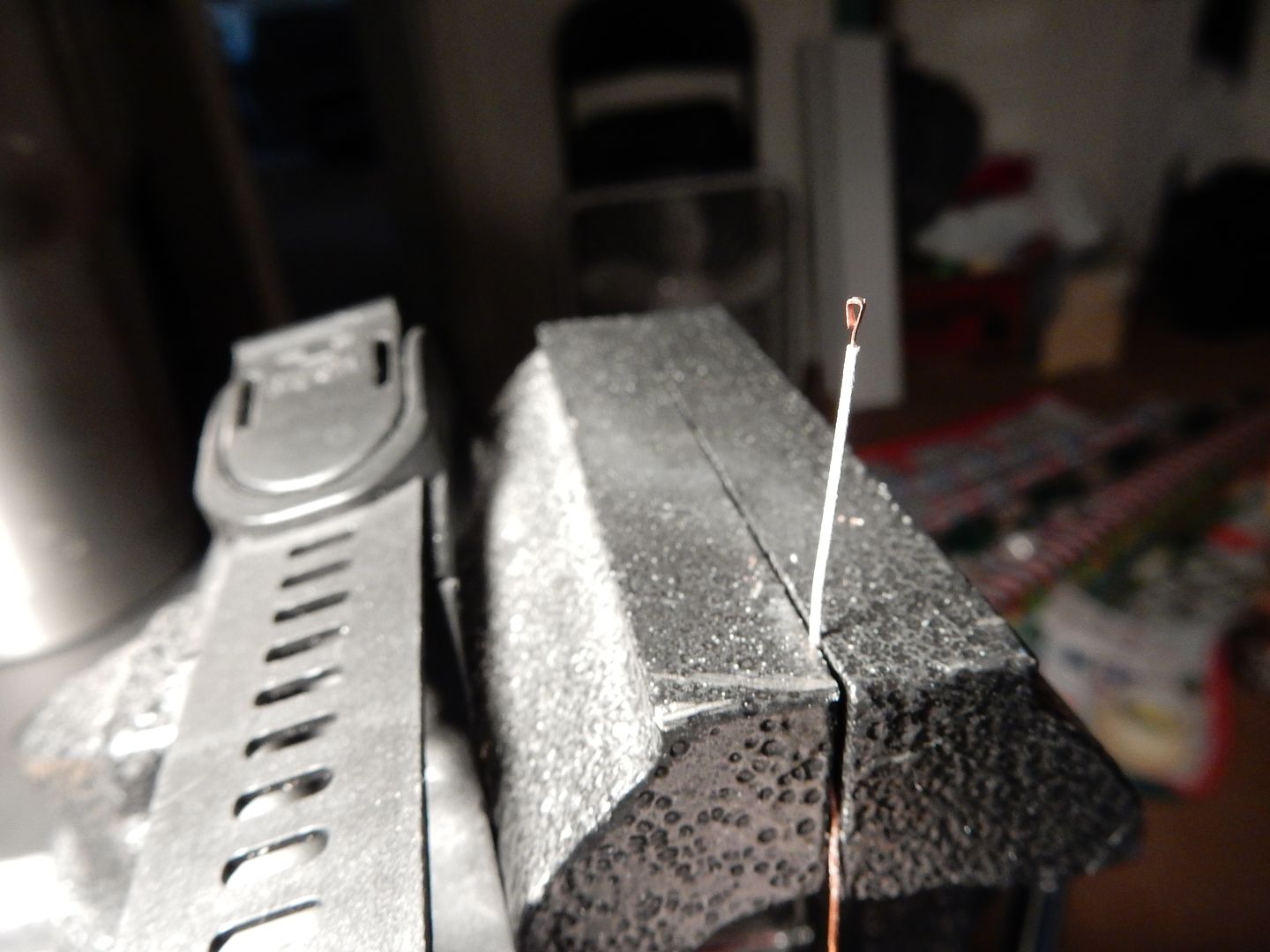

Then drill a fairly deep hole in it:

like so:

Then take a smaller piece of copper wire and hammer the end out to flatten it and wrap it around a drill bit to form the engine oil level indicator stick

and trim the bottom off to where it's not so long and insert that all into the "tube":

and then paint it all up and install it into the engine. And now we have the fuel line, filter and dipstick tube with indicator handle all painted, installed and purdy'd up with no where to go:

Still adding some detail to the engine here and there but caught up to where I'm at now with it. More coming......